Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Starter motor turns, but engine does not turnСодержание книги

Поиск на нашем сайте

• Faulty starter clutch • Damaged reduction gear • Damaged starter driven gear • Damaged or faulty starter motor pinion gear

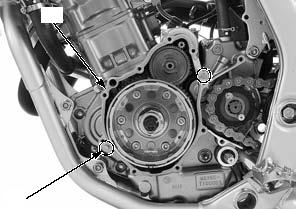

COMPONENT LOCATION

128 N·m (13.1 kgf·m, 94 lbf·ft)

13-2 ALTERNATOR/STARTER CLUTCH

LEFT CRANKCASE COVER

REMOVAL

Drain the engine oil (page 3-9).

Remove the following:

– Left side cover (page 2-3) – Drive sprocket cover (page 2-6) – Gearshift pedal (page 12-14)

Disconnect the following:

– Alternator 3P connector [1] – CKP sensor/neutral switch 3P (Black) connector [2]

Release the alternator wire [3] from the clamp [4].

Disconnect the neutral switch connector [1] and release the wire from the left crankcase cover groove.

The left crankcase Loosen the left crankcase cover bolts [2] in a crisscross cover (stator) is pattern in 2 or 3 steps and remove the bolts and left

magnetically crankcase cover [3]. attracted to the flywheel, be careful during removal.

Remove the dowel pins [1] and gasket [2].

INSTALLATION

Be careful not to Clean any gasket material from the mating surfaces of damage the mating the left crankcase and cover. surfaces. Install the dowel pins [1] and a new gasket [2].

[1] [3]

[2]

[2]

[3]

[2]

[1]

[1]

[4]

[1]

13-3 ALTERNATOR/STARTER CLUTCH

The left crankcase cover (stator) is magnetically attracted to the flywheel, be careful during installation.

Install the left crankcase cover [1] and bolts [2]. Tighten the bolts in a crisscross pattern in 2 or 3 steps.

Connect the neutral switch connector [3] and set the wire into the left crankcase cover groove.

Connect the following:

– Alternator 3P connector [1] – CKP sensor/neutral switch 3P (Black) connector [2]

Secure the alternator wire [3] with the clamp [4]. Install the following: – Gearshift pedal (page 12-17) – Drive sprocket cover (page 2-6) – Left side cover (page 2-3)

Fill the engine with the recommended engine oil (page 3-9).

[2]

[1] [3]

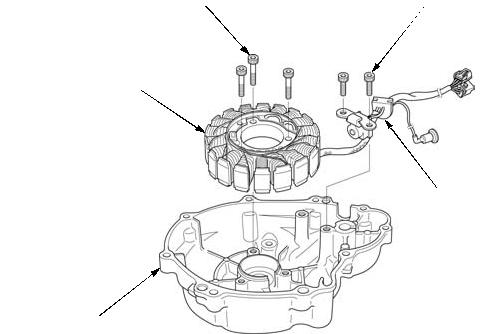

STATOR/CKP SENSOR

REMOVAL/INSTALLATION

Remove and install the stator/CKP sensor as following illustration.

• Apply locking agent to the CKP sensor mounting bolt threads as specified (page 1-12).

• Apply sealant to the alternator/CKP sensor wire grommet sealing surface (page 1-15).

STATOR/CKP SENSOR

GROMMET

LEFT CRANKCASE COVER

13-4 ALTERNATOR/STARTER CLUTCH

FLYWHEEL

REMOVAL

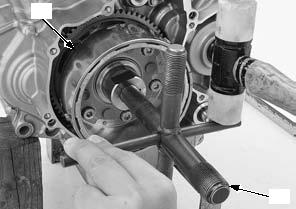

Remove the left crankcase cover (page 13-3). Remove the starter reduction gear [1] and shaft [2].

Hold the flywheel with the special tool and remove the flywheel bolt [1] and washer [2].

Remove the flywheel [1] using the special tool.

Remove the needle bearing [1].

Be careful not to Remove the woodruff key [2]. damage the key groove and crankshaft.

[1]

[2]

[1]

[2]

[2]

[1]

13-5 ALTERNATOR/STARTER CLUTCH

INSPECTION

Inspect the following parts for scratch, damage, abnormal wear and deformation. Replace if necessary.

– Starter reduction gear shaft – Starter reduction gear – Woodruff key – Needle bearing

INSTALLATION

Apply molybdenum oil solution to the needle bearing [1] rotating area.

Install the needle bearing onto the crankshaft. Clean any oil from the crankshaft taper surface.

Be careful not to Install the woodruff key [2] onto the crankshaft. damage the key groove and crankshaft.

Install the flywheel while aligning the woodruff key on the crankshaft with flywheel keyway.

Apply engine oil to the flywheel bolt [1] threads and seating surface.

Install the washer [2] and bolt.

Hold the flywheel with a special tool and tighten the bolt to the specified torque.

TORQUE:128 N·m (13.1 kgf·m, 94 lbf·ft)

[3]

[2]

Align

[2]

13-6 ALTERNATOR/STARTER CLUTCH

Apply molybdenum oil solution to the starter reduction gear shaft [1] outer surface and starter reduction gear [2] inner surface.

Install the shaft and starter reduction gear. Install the left crankcase cover (page 13-3).

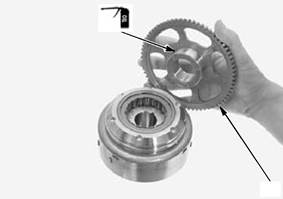

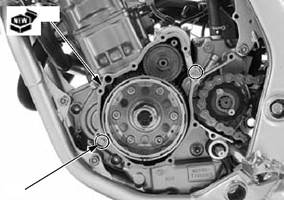

STARTER CLUTCH

REMOVAL

Remove the flywheel (page 13-5).

Make sure that the starter driven gear [1] turns counterclockwise smoothly and does not turn clockwise.

Remove the starter driven gear while turning it counterclockwise.

Remove the starter clutch outer and starter one-way clutch.

INSPECTION

Inspect the following parts for scratch, damage, abnormal wear and deformation. Replace if necessary.

– Starter driven gear

Measure each part according to ALTERNATOR/ STARTER CLUTCH SPECIFICATIONS (page 1-7). Replace any part if it is out of service limit.

[2]

[1]

[1]

[1]

13-7 ALTERNATOR/STARTER CLUTCH

INSTALLATION

STARTER DRIVEN GEAR

STARTER CLUTCH OUTER

STARTER ONE-WAY CLUTCH

FLYWHEEL

30 N·m (3.1 kgf·m, 22 lbf·ft)

[2]

TORQUE:30 N·m (3.1 kgf·m, 22 lbf·ft)

[2]

13-8 ALTERNATOR/STARTER CLUTCH

Apply engine oil to the starter driven gear [1] sliding surface.

Install the starter driven gear while turning it counterclockwise.

[1]

Make sure that the starter driven gear turns counterclockwise smoothly and does not turn clockwise.

Install the flywheel (page 13-6).

13-9

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Последнее изменение этой страницы: 2016-04-08; просмотров: 349; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 3.129.23.110 (0.007 с.) |

[2]

[2]