Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Ignition coil primary peak voltageСодержание книги

Поиск на нашем сайте

Shift the transmission into neutral and disconnect the spark plug cap (page 3-5).

Connect a known good spark plug [1] to the spark plug cap [2] and ground it to the cylinder head as done in a spark test.

[1]

[2]

Avoid touching the spark plug and tester probes to prevent electric shock.

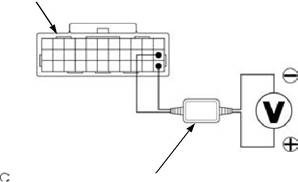

With the ignition coil primary wire connected, connect

TOOL:

Imrie diagnostic tester (model 625) or

with commercially available digital multimeter (impedance 10 MΩ/DCV minimum)

CONNECTION: Green/red (+) – Ground (–)

Shift the transmission into neutral.

Turn the ignition switch ON and engine stop switch "

Crank the engine with the starter motor with the throttle grip fully opened and read ignition coil primary peak voltage.

PEAK VOLTAGE: 100 V minimum

If the peak voltage is abnormal, follow the checks described in the troubleshooting table (page 5-2).

5-4 IGNITION SYSTEM

CKP SENSOR PEAK VOLTAGE

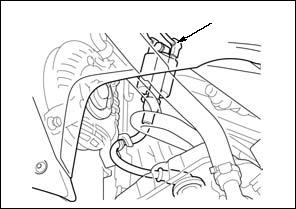

Remove the reserve tank cover (page 2-4).

[1]

Disconnect the ECM 33P (Black) connector [1].

5-5 IGNITION SYSTEM

IGNITION TIMING

Connect the timing light [1] to the spark plug wire.

Start the engine and let it idle.

IDLE SPEED: 1,450 ± 100 min-1 (rpm)

Apply engine oil to a new O-ring and install it to the timing hole cap.

Apply engine oil to the timing hole cap threads.

Install and tighten the timing hole cap to the specified torque.

TORQUE:6.0 N·m (0.6 kgf·m, 4.4 lbf·ft)

IGNITION COIL

REMOVAL/INSTALLATION

Disconnect the spark plug cap [1].

Disconnect the primary wire connectors [2] from the ignition coil.

Release the spark plug wire [3] from the guides [4] on the fan motor shroud.

Remove the bolts [5], spacers [6] and ignition coil [7]. Installation is in the reverse order of removal.

[5]/[6] [2]

[4]

[3] [1]

5-6 ELECTRIC STARTER SYSTEM

SERVICE INFORMATION·····························6-2 STARTER MOTOR ·······································6-4

TROUBLESHOOTING···································6-2 STARTER RELAY SWITCH ·························6-8

SYSTEM LOCATION·····································6-3 NEUTRAL DIODE ·········································6-9

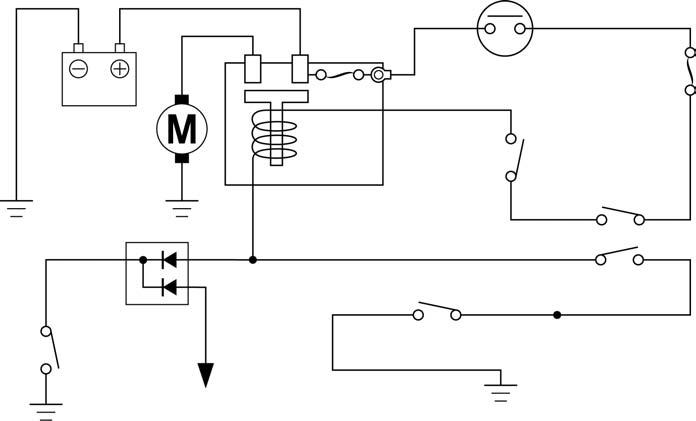

SYSTEM DIAGRAM ······································6-3

6-1 ELECTRIC STARTER SYSTEM

SERVICE INFORMATION

GENERAL

• When servicing the starter system, always follow the steps in the troubleshooting flow chart (page 6-2). • A weak battery may be unable to turn the starter motor quickly enough, or supply adequate ignition current.

TROUBLESHOOTING

6-2

SYSTEM LOCATION

ENGINE STOP SWITCH ELECTRIC STARTER SYSTEM

STARTER SWITCH

MAIN FUSE (30 A)

FI. IGN FUSE (10 A)

STARTER MOTOR

NEUTRAL SWITCH

SYSTEM DIAGRAM

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Последнее изменение этой страницы: 2016-04-08; просмотров: 587; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 3.149.29.192 (0.009 с.) |

the peak voltage adaptor or Imrie tester to the ignition [1] coil primary terminal [1] and ground.

the peak voltage adaptor or Imrie tester to the ignition [1] coil primary terminal [1] and ground.

".

".

CKP sensor connector.

CKP sensor connector.

[7]

[7]