Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Torque - Caliper Mounting BoltsСодержание книги

Поиск на нашем сайте

Front: 34 N·m (3.5 kgf·m, 25 ft·lb) Rear: 25 N·m (2.5 kgf·m, 18 ft·lb) Brake Hose Banjo Bolts: 25 N·m (2.5 kgf·m, 18 ft·lb) • Check the fluid level in the brake reservoirs. • Bleed the brake line (see Brake Line Bleeding). • Check the brake for good braking power, no brake drag,

and no fluid leakage.

Front Caliper Disassembly • Refer to the Caliper Rubber Parts Replacement in the Pe- riodic Maintenance chapter. Front Caliper Assembly • Refer to the Caliper Rubber Parts Replacement in the Pe- riodic Maintenance chapter. Rear Caliper Disassembly • Refer to the Caliper Rubber Parts Replacement in the Pe- riodic Maintenance chapter. Rear Caliper Assembly • Refer to the Caliper Rubber Parts Replacement in the Pe- riodic Maintenance chapter.

The fluid seal (piston seal) [A] is placed around the pis- ton to maintain clearance between the pad and the disc. If the seal is in a poor condition, it could lead the pad to wear excessively or the brake to drag, which may cause the tem- perature of the discs or the brake fluid to increase. • Replace the fluid seal if it exhibits any of the conditions listed below. ○Brake fluid leakage around the pad. ○Brakes overheat.

○Seal and piston are stuck together.

well. Also, replace all seals every other time the pads are changed.

• Check that the dust boot [A] and friction boot [B] are not cracked, worn, swollen, or otherwise damaged.

scores or rusty.

The caliper body must slide smoothly on the caliper holder shafts [A]. If the body does not slide smoothly, one pad will wear more than the other, pad wear will increase, and con- stant drag on the disc will raise brake and brake fluid tem- perature. • Check to see that the caliper holder shafts are not badly worn or stepped, and that the rubber friction boots are not damaged.

Front Brake Pad Removal

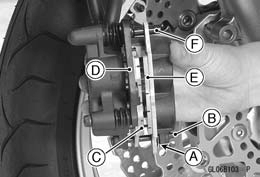

• Draw out the holder shaft pin [A], and take off the holder shaft [B]. • Remove the pad [C] on the piston side. • Push the holder [D] towards the piston, and remove the pad of the other side [E] from the holder shaft [F].

Front Brake Pad Installation • Push the caliper pistons in by hand as far as they will go. • Install the anti-rattle spring in its correct position. • Install the pad on the piston side first, then install the other pad on the holder.

• Remove the rear caliper with the hose installed (see Rear Caliper Removal). • Draw out the holder shaft pin [A], and take off the holder shaft [B]. • Remove the pad [C] on the piston side. • Push the holder [D] towards the piston, and remove the pad of the other side [E] from the holder shaft [F].

Rear Brake Pad Installation • Push the caliper piston in by hand as far as it will go. • Install the anti-rattle spring in its correct position. • Install the pad on the piston side first, then install the other pad on the holder.

Brake Pad Wear Inspection • Refer to the Brake Pad Wear Inspection in the Periodic Maintenance chapter.

Front Master Cylinder Removal

stallation).

• Unscrew the clamp bolts [B], and take off the master cylin- der as an assembly with the reservoir, brake lever and

brake switch installed.

Brake Lever Pivot Bolt [A] and Locknut Brake Lever [B] Front Brake Light Switch [C]

• Install the front master cylinder so that the punch mark [A] of the handlebar is aligned with the mating surface [B] of the master cylinder clamp to level the reservoir.

• Tighten the upper clamp bolt [B] first, and then the lower clamp bolt [C]. There will be a gap at the lower part of the clamp after tightening. Torque - Front Master Cylinder Clamp Bolts: 8.8 N·m (0.90 kgf·m, 78 in·lb) • Replace the washers on each side of the hose fitting with new ones. • Tighten the brake hose banjo bolt. Torque - Brake Hose Banjo Bolt: 25 N·m (2.5 kgf·m, 18 ft·lb) • Bleed the brake line (see Brake Line Bleeding). • Check the brake for good braking power, no brake drag, and no fluid leakage.

Rear Master Cylinder Removal

• Remove the cotter pin [B]. NOTE ○Pulloff the joint pin while pressing down the brake pedal. • Pull off the reservoir hose lower end [C], and drain the brake fluid into a container. • Remove the master cylinder.

• Replace the cotter pin [A] with a new one. • Replace the washers on each side of hose fitting with new ones. • Tighten the following bolts. Torque - Rear Master Cylinder Mounting Bolts: 25 N·m (2.5 kgf·m, 18 ft·lb) Brake Hose Banjo Bolt: 25 N·m (2.5 kgf·m, 18 ft·lb) • Bleed the brake line (see Brake Line Bleeding). • Check the brake for good braking power, no brake drag, and no fluid leakage. Front Master Cylinder Disassembly • Refer to the Master Cylinder Rubber Parts Replacement in the Periodic Maintenance chapter. Rear Master Cylinder Disassembly • Refer to the Master Cylinder Rubber Parts Replacement in the Periodic Maintenance chapter. Master Cylinder Assembly • Refer to the Master Cylinder Rubber Parts Replacement in the Periodic Maintenance chapter.

• Remove the master cylinders (see Front/Rear Master Cylinder Removal). • Disassemble the front and rear master cylinders. • Check that there are no scratches, rust or pitting on the inner wall [A] of each master cylinder and on the outside of each piston [B].

• Inspect the primary cup [C] and secondary cup [D].

the piston assembly should be replaced to renew the cups.

Front Master Cylinder [J]

• Check the piston return springs [F] for any damage.

• Check that relief port [G] and supply port [H] are not plugged.

Rear Master Cylinder [K]

Brake Disc Removal • Remove the wheel (see Front/Rear Wheel Removal in the Wheels/Tires chapter). • Unscrew the mounting bolts, and take off the disc.

Brake Disc Installation • Replace the gaskets with new ones. • Install the brake disc on the wheel so that the marked side [A] faces out. • Apply a non-permanent locking agent to the threads of the front and rear brake disc mounting bolts [B]. • Tighten: Torque - Brake Disc Mounting Bolts: 27 N·m (2.8 kgf·m, 20 ft·lb)

• Measure the thickness of each disc [A] at the point where it has worn the most.

Brake Discs Thickness Standard: Front: EX650A Models 4.3 ~ 4.7 mm (0.17 ~ 0.19 in.) EX650B Models 4.8 ~ 5.2 mm (0.19 ~ 0.20 in.) Rear 4.8 ~ 5.2 mm (0.19 ~ 0.20 in.) Service Limit: Front 4.0 mm (0.16 in.) Rear 4.5 mm (0.18 in.)

• Raise the wheel off the ground with jack (see Front/Rear Wheel Removal in the Wheels/Tires chapter).

|

||||||||||||

|

Последнее изменение этой страницы: 2016-08-10; просмотров: 299; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 18.218.231.116 (0.006 с.) |

Caliper Fluid Seal Damage

Caliper Fluid Seal Damage ○Considerable difference in inner and outer pad wear.

○Considerable difference in inner and outer pad wear. If the fluid seal is replaced, replace the dust seal [B] as

If the fluid seal is replaced, replace the dust seal [B] as Rear Caliper Dust Boot and Friction Boot Damage

Rear Caliper Dust Boot and Friction Boot Damage Caliper Piston and Cylinder Damage

Caliper Piston and Cylinder Damage

Rear Caliper Holder Shaft Wear

Rear Caliper Holder Shaft Wear • Remove the front caliper with the hose installed (see Front Caliper Removal).

• Remove the front caliper with the hose installed (see Front Caliper Removal).

Rear Brake Pad Removal

Rear Brake Pad Removal

• Remove the banjo bolt [A] to disconnect the brake hose from the master cylinder [B] (see Brake Hose Removal/In-

• Remove the banjo bolt [A] to disconnect the brake hose from the master cylinder [B] (see Brake Hose Removal/In- • Disconnect the front brake light switch connectors [A].

• Disconnect the front brake light switch connectors [A]. • Remove:

• Remove: Front Master Cylinder Installation

Front Master Cylinder Installation • The master cylinder clamp must be installed with the ar- row mark [A] upward.

• The master cylinder clamp must be installed with the ar- row mark [A] upward. • Unscrew the brake hose banjo bolt [A] on the master cylin- der (see Brake Hose Removal/Installation).

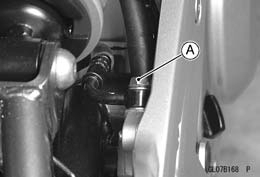

• Unscrew the brake hose banjo bolt [A] on the master cylin- der (see Brake Hose Removal/Installation). • Unscrew the master cylinder mounting bolts [A].

• Unscrew the master cylinder mounting bolts [A]. Rear Master Cylinder Installation

Rear Master Cylinder Installation Master Cylinder Inspection

Master Cylinder Inspection • Check the dust covers [E] for damage. If they are damaged, replace them.

• Check the dust covers [E] for damage. If they are damaged, replace them. • Remove the gaskets.

• Remove the gaskets. Brake Disc Wear

Brake Disc Wear If the disc has worn past the service limit, replace it. Measuring Area [B]

If the disc has worn past the service limit, replace it. Measuring Area [B] Brake Disc Warp

Brake Disc Warp