Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

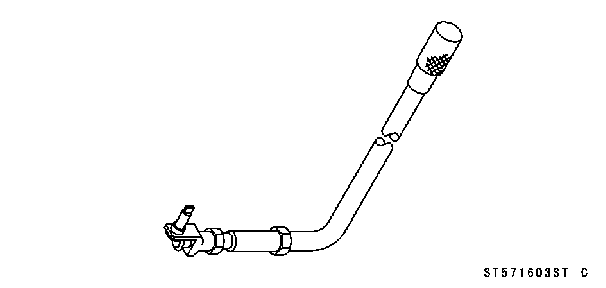

Pilot Screw Adjuster, E: 57001-1603Содержание книги

Поиск на нашем сайте

Fuel System (DFI) Air Cleaner Element Cleaning NOTE ○In dusty areas, the element should be cleaned more frequently than the recommended interval. ○After riding through rain or on muddily roads, the ele- ment should be cleaned immediately.

Fuel Tank (see Fuel Tank Removal in the Fuel System (DFI) chapter) Air Switching Valve Hose [A] (Disconnect) Air Cleaner Element Screw [B] Air Cleaner Element [C]

Upper Plastic Holder [A] Element [B]

○The wire screen [A] is fastened with an adhesive for the shaded portion [B]. Do not remove the wire screen.

and then dry it with compressed air or by shaking it. • After cleaning, saturate a clean, lint-free towel with SE, SF, or SG class SAE 30 oil and apply the oil to the element by tapping the element outside with the towel. • Visually check the element for tears or breaks. • If the element has any tears or breaks, replace the ele- ment.

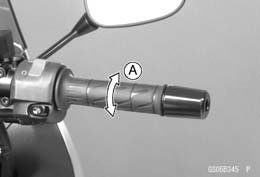

• Check that the throttle grip moves smoothly from full open to close [A], and the throttle closes quickly and completely by the return spring in all steering positions.

Throttle Grip Free Play Standard: 2 ~ 3 mm (0.08 ~ 0.12 in.)

• Loosen the locknut [A] at the upper end of the accelerator cable. • Turn the adjuster [B] in completely so as to give the throttle grip plenty of play.

• Loosen the locknut [A] at the middle of the decelerator cable. • Turn the adjuster [B] until there is no play when the throttle grip is completely closed. • Tighten the locknut. • Turn the accelerator cable adjuster until the proper amount of throttle grip free play is obtained. • Tighten the locknut.

NOTE ○These procedures are explained on the assumption that the inlet and exhaust systems of the engine are in good condition. • Situate the motorcycle so that it is vertical. • Remove the center fairings (see Center Fairing Removal in the Frame chapter). • Pull off the rubber caps [A] from the fitting of each throttle body (In the photo, the throttle body has been removed

for clarity.). • Connect a commercially available vacuum gauge and hoses [A] to the fittings of the throttle body as shown.

coil primary leads.

• Check the idle speed. Tachometer [A] • Open and close the throttle.

If the idle speed is out of the specified range, adjust it. If the idle speed is out of the specified range, adjust it.• While idling the engine, inspect the engine vacuum, using the vacuum gauge [B]. Engine Vacuum Standard: 35.3 ±1.3 kPa (265 ±10 mmHg) at Idle Speed 1 300 ±50 r/min (rpm)

Special Tool - Pilot Screw Adjuster, E [A]: 57001-1603

#1 [A] and #2 [B] to the lower vacuum. • Open and close the throttle valves after each measure- ment and adjust the idle speed as necessary. • Inspect the vacuums as before.

gine vacuum synchronization.

○Check the bypass screw and its hole for carbon deposits.

screw and the hole, using a cotton pad penetrated with a high-flash point solvent. ○Replace the O-ring with a new one. ○Check the tapered portion [E] of the bypass screw for wear or damage.

• Turn in the bypass screw until it seats fully but not tightly.

• Repeat the same procedure for other bypass screws. • Repeat the synchronization.

the main throttle sensor (see Main Throttle Sensor Output Voltage Inspection in the Fuel System (DFI) chapter).

|

||||||||||||||||

|

Последнее изменение этой страницы: 2016-08-10; просмотров: 575; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 3.144.6.144 (0.006 с.) |

Oil Filter Wrench: 57001-1249

Oil Filter Wrench: 57001-1249

• Remove:

• Remove: • Remove:

• Remove: NOTE

NOTE

• Clean the element [A] in a bath of high-flash point solvent,

• Clean the element [A] in a bath of high-flash point solvent, • Install the element unit [A] with the foam element side (gray) [B] facing down.

• Install the element unit [A] with the foam element side (gray) [B] facing down. Throttle Control System Inspection

Throttle Control System Inspection • Check the throttle grip free play [A].

• Check the throttle grip free play [A]. If necessary, adjust the throttle cable as follows.

If necessary, adjust the throttle cable as follows. • Remove the right center fairing (see Center Fairing Re- moval in the Frame chapter).

• Remove the right center fairing (see Center Fairing Re- moval in the Frame chapter). Engine Vacuum Synchronization Inspection

Engine Vacuum Synchronization Inspection • Connect a highly accurate tachometer to one of the stick

• Connect a highly accurate tachometer to one of the stick • Start the engine and warm it up thoroughly.

• Start the engine and warm it up thoroughly. If any one vacuum is not within the specification, turn in the bypass screws until it seats fully but not tightly.

If any one vacuum is not within the specification, turn in the bypass screws until it seats fully but not tightly. • Turn out the bypass screw of the higher vacuum between

• Turn out the bypass screw of the higher vacuum between • Remove the bypass screw [A], spring [B], washer [C] and O-ring [D].

• Remove the bypass screw [A], spring [B], washer [C] and O-ring [D].