Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Sealant - Kawasaki Bond: 92104-1064Содержание книги

Поиск на нашем сайте

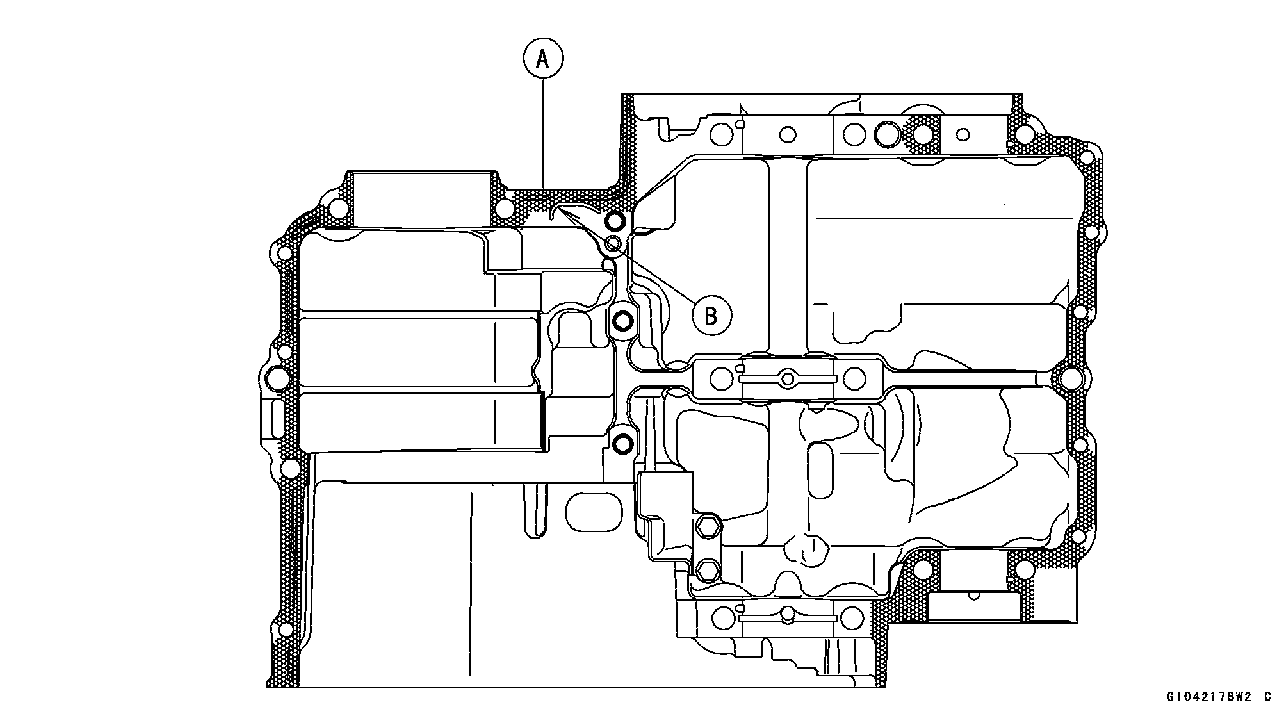

NOTE ○Especially, apply a liquid gasket carefully so that it shall be filled up on the grooves.

○Do not apply liquid gasket to the oil passage [B].

○Insert [A] the breather pipe [B] on the upper crankcase half through the hole [C] on the lower crankcase half. NOTE ○Make the application finish within 20 minutes when the liquid gasket to the mating surface of the lower crankcase half is applied. ○Moreover fit the case and tighten the case bolts just after finishing the application of the liquid gasket.

• Apply molybdenum disulfide oil solution to both sides [A] of the M9 bolts washers and the threads [B] of the M9 bolts.

[7 ~ 10] only (see the next figure).

○Following the sequence numbers on the lower crankcase half, tighten the M9 bolts [1, 2] L= 113 mm (4.45 in.) with washers. Torque - Crankcase Bolts (M9): 44 N·m (4.5 kgf·m, 32 ft·lb) ○Tightenthe M9 bolts [3, 4] L= 83 mm (3.27 in.) with wash- ers. Torque - Crankcase Bolts (M9): 44 N·m (4.5 kgf·m, 32 ft·lb) ○Tighten the M9 bolts [5, 6] L= 113 mm (4.45 in.) with washers. Torque - Crankcase Bolts (M9): 44 N·m (4.5 kgf·m, 32 ft·lb) ○Tighten the M8 bolts [7 ~10]. Torque - Crankcase Bolts (M8): 35 N·m (3.6 kgf·m, 26 ft·lb) ○Tighten the M8 bolts [A] (Do not apply molybdenum oil solution). Torque - Crankcase Bolts (M8): 27.5 N·m (2.8 kgf·m, 20 ft·lb) ○Tighten the M6 bolts [B]. Torque - Crankcase Bolts (M6): 19.6 N·m (2.0 kgf·m, 15 ft·lb)

○The upper crankcase bolts have copper plated washers. Replace them with new ones. Torque - Upper Crankcase Bolts [A]: 27.5 N·m (2.8 kgf·m, 20 ft·lb) • After tightening all crankcase bolts, check the following items. ○Crankshaft and balancer shafts turn freely.

Crankshaft Removal

• Remove the crankshaft [A].

Crankshaft Installation Crankshaft Installation

• Apply molybdenum disulfide oil solution to the crankshaft main bearing inserts. ○Align [A] the timing mark on the balancer gear [B] with the timing mark on the balancer drive gear [C] of the crank- shaft.

• Split the crankcase (see Crankcase Splitting). • Remove the connecting rod nuts [A]. • Remove the crankshaft. NOTE ○Mark and record the locations of the connecting rods and their big end caps so that they can be reassembled in their original positions.

Connecting Rod Installation

Big End Cap [A] Connecting Rod [B] Weight Mark, Alphabet [C] Diameter Mark [D]: “○” or no mark

necting rod big end. • Apply molybdenum disulfide oil solution [B] to the inner surfaces of upper and lower bearing inserts. ○The molybdenum disulfide oil solution is a mixture of en- gine oil and molybdenum disulfide grease with a weight ratio (10: 1). ○Do not apply any grease or oil [C] to the cap inside and cap insert outside. ○Install the inserts so that their nails [D] are on the same side and fit them into the recess of the connecting rod and

cap. ○When installing the inserts [A], be careful not to damage the insert surface with the edge of the connecting rod [B] or the cap [C]. One way to install inserts is as follows.

Installation [E] to Connecting Rod Push [F] Spare Dowel Pin [G] Connecting Rod Bolts [H] • Install the cap on the connecting rod, aligning the weight and diameter marks. • Remove debris and clean the surface of inserts. • Apply molybdenum disulfide oil solution [MO] to the threads and seating surfaces of the big end nuts and bolts.

• Install each connecting rod on its original crankpin. NOTE ○Install each connecting rod so that its oil jet [A] faces the exhaust side (the front [B]) (see Engine Oil Flow Chart in the Engine Lubrication System chapter). ○The connecting rod big end is bolted using the “plastic region fastening method”. ○This method precisely achieves the needed clamping force without exceeding it unnecessarily, allowing the use of thinner, lighter bolts further decreasing connecting rod weight. ○There are two types of the plastic region fastening. One is a bolt length measurement method and other is a rotation

angle method. Observe one of the following two, but the bolt length measurement method is preferable because this is a more reliable way to tighten the big end nuts.

(1) Bolt Length Measurement Method • Be sure to clean the bolts, nuts, and connecting rods thoroughly with a high-flash point solvent, because the new connecting rods, bolts, and nuts are treated with an anti-rust solution.

• Dent both bolt head and bolt tip with a punch as shown. • Before tightening, use a point micrometer [A] to measure the length of new connecting rod bolts and record the val- ues to find the bolt stretch. Connecting Rod [B] Mark here with a punch [C]. Nuts [D] Fit micrometer pins into punch marks [E]. • Apply a small amount of molybdenum disulfide oil solution to the following. Threads of Nuts and Bolts Seating Surfaces of Nuts and Con-rods • Tighten the big end nuts until the bolt elongation reaches the length specified in the table. • Check the length [F] of the connecting rod bolts.

stretched too much. An overelongated bolt may break in use. Bolt Length after tightening – Bolt Length before tightening = Bolt Stretch

(2) Rotation Angle Method

• Be sure to clean the bolts and nuts thoroughly with a high -flash point solvent, because the new bolts and nuts are treated with an anti-rust solution.

• Apply a small amount of molybdenum disulfide oil solution to the following. Threads [A] of Nuts and Bolts Seating Surfaces [B] of Nuts and Con-rods

• Next, tighten the nuts 120° ±5°. ○Mark [A] the connecting rod big end caps and nuts so that nuts can be turned 120° [B] properly.

Crankshaft/Connecting Rod Cleaning • After removing the connecting rods from the crankshaft, clean them with a high-flash point solvent. • Blow the crankshaft oil passages with compressed air to remove any foreign particles or residue that may have accumulated in the passages.

• Remove the connecting rod big end bearing inserts, and reinstall the connecting rod big end cap. • Select an arbor [A] of the same diameter as the connect- ing rod big end, and insert the arbor through the connect- ing rod big end. • Select an arbor of the same diameter as the piston pin and at least 100 mm (3.94 in.) long, and insert the arbor [B] through the connecting rod small end. • On a surface plate, set the big-end arbor on V block [C]. • With the connecting rod held vertically, use a height gauge to measure the difference in the height of the

Connecting Rod Bend

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Последнее изменение этой страницы: 2016-08-10; просмотров: 494; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 3.145.156.17 (0.009 с.) |

• Fit the lower crankcase half to the upper crankcase half.

• Fit the lower crankcase half to the upper crankcase half. ○The M9 bolts [1 ~6] (see the next figure) have copper plated washers. Replace them with new ones.

○The M9 bolts [1 ~6] (see the next figure) have copper plated washers. Replace them with new ones. • Apply molybdenum disulfide oil solution to flange [A] and the threads [B] of the M8 bolts which is tightening order is

• Apply molybdenum disulfide oil solution to flange [A] and the threads [B] of the M8 bolts which is tightening order is • Tighten the lower crankcase bolts using the following steps.

• Tighten the lower crankcase bolts using the following steps. • Tighten the upper crankcase bolts.

• Tighten the upper crankcase bolts. • Split the crankcase (see Crankcase Splitting).

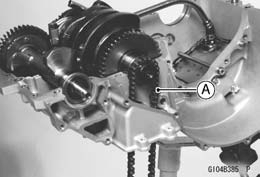

• Split the crankcase (see Crankcase Splitting). • Install the crankshaft with the camshaft chain [A] hanging on it.

• Install the crankshaft with the camshaft chain [A] hanging on it. Connecting Rod Removal

Connecting Rod Removal

• Apply molybdenum disulfide grease [A] to the outer sur- face of the upper insert and the inner surface of the con-

• Apply molybdenum disulfide grease [A] to the outer sur- face of the upper insert and the inner surface of the con- Installation [D] to Cap

Installation [D] to Cap • Install the crankshaft (see Crankshaft Installation).

• Install the crankshaft (see Crankshaft Installation).

• Install new bolts in reused connecting rods.

• Install new bolts in reused connecting rods. If the stretch is more than the usable range, the bolt has

If the stretch is more than the usable range, the bolt has

• Install new bolts in reused connecting rods.

• Install new bolts in reused connecting rods. • First, tighten the nuts to the specified torque. See the table below.

• First, tighten the nuts to the specified torque. See the table below. Connecting Rod Bend

Connecting Rod Bend