Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Service Limit: 83.10 mm (3.2716 in.)Содержание книги

Поиск на нашем сайте

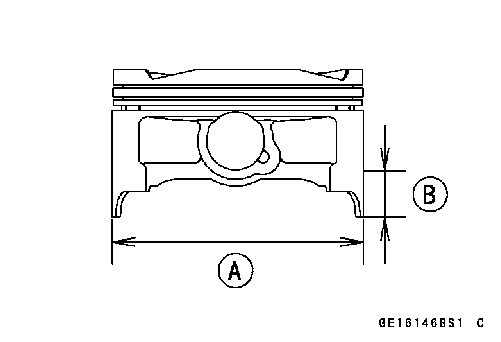

• Measure the outside diameter [A] of each piston 18 mm (0.7087 in.) [B] up from the bottom of the piston at a right angle to the direction of the piston pin.

Piston Diameter Standard: 82.969 ~ 82.984 mm (3.2665 ~ 3.2671 in.) Service Limit: 82.82 mm (3.2606 in.)

• Check for uneven groove wear by inspecting the ring seat- ing.

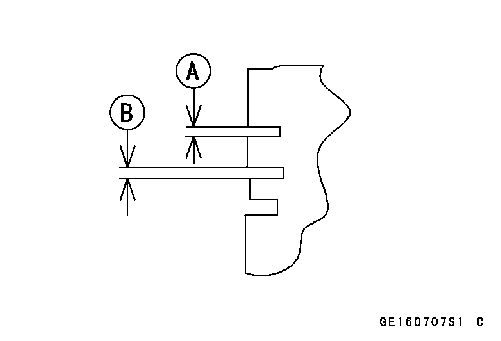

• With the piston rings in their grooves, make several mea- surements with a thickness gauge [A] to determine piston ring/groove clearance. Piston Ring/Groove Clearance Top Standard: 0.03 ~ 0.07 mm (0.0012 ~ 0.0028 in.) Service Limit: 0.17 mm (0.0067 in.) Second Standard: 0.02 ~ 0.06 mm (0.0008 ~ 0.0024 in.) Service Limit: 0.16 mm (0.0063 in.)

• Measure the piston ring groove width. ○Use a vernier caliper at several points around the piston. Piston Ring Groove Width Top [A] Standard: 0.92 ~ 0.94 mm (0.0362 ~ 0.0370 in.) Service Limit: 1.02 mm (0.040 in.) Second [B] Standard: 1.01 ~ 1.03 mm (0.0398 ~ 0.0406 in.) Service Limit: 1.11 mm (0.044 in.)

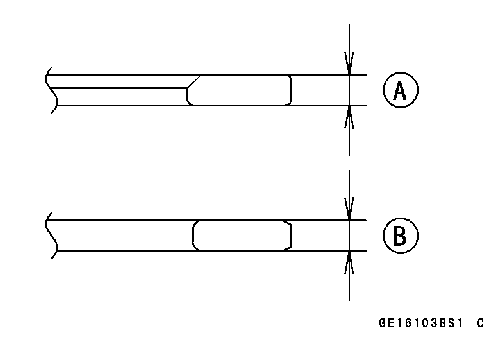

• Measure the piston ring thickness. ○Use the micrometer to measure at several points around the ring. Piston Ring Thickness Top [A] Standard: 0.87 ~ 0.89 mm (0.0342 ~ 0.0350 in.) Service Limit: 0.80 mm (0.031 in.) Second [B] Standard: 0.97 ~ 0.99 mm (0.0382 ~ 0.0390 in.) Service Limit: 0.90 mm (0.035 in.)

NOTE ○When using new rings in a used piston, check for un- even groove wear. The rings should fit perfectly parallel to the groove sides. If not, replace the piston.

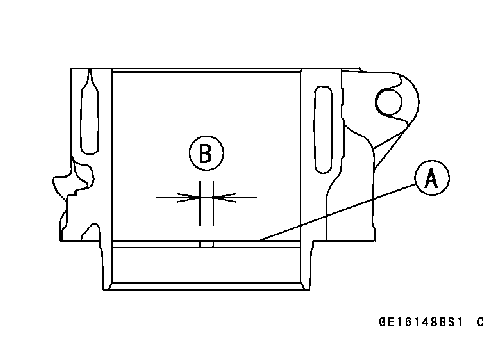

• Place the piston ring [A] inside the cylinder, using the pis- ton to locate the ring squarely in place. Set it close to the bottom of the cylinder, where cylinder wear is low. • Measure the gap [B] between the ends of the ring with a thickness gauge. Piston Ring End Gap Top Standard: 0.25 ~ 0.40 mm (0.0098 ~ 0.0157 in.) Service Limit: 0.7 mm (0.028 in.) Second Standard: 0.40 ~ 0.55 mm (0.0157 ~ 0.0217 in.) Service Limit: 0.8 mm (0.031 in.)

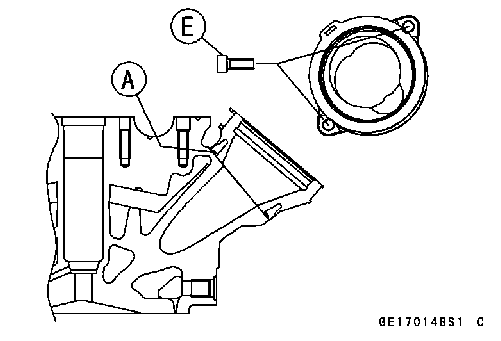

Throttle Body Holder Installation

• Install the clamps [B] as shown and so that their projec- tions fit [C] on the holes of the holders. ○Be sure that the clamp bolt heads [D] face outwards. • Tighten: Torque - Throttle Body Holder Bolts [E]: 12 N·m (1.2 kgf·m, 106 in·lb)

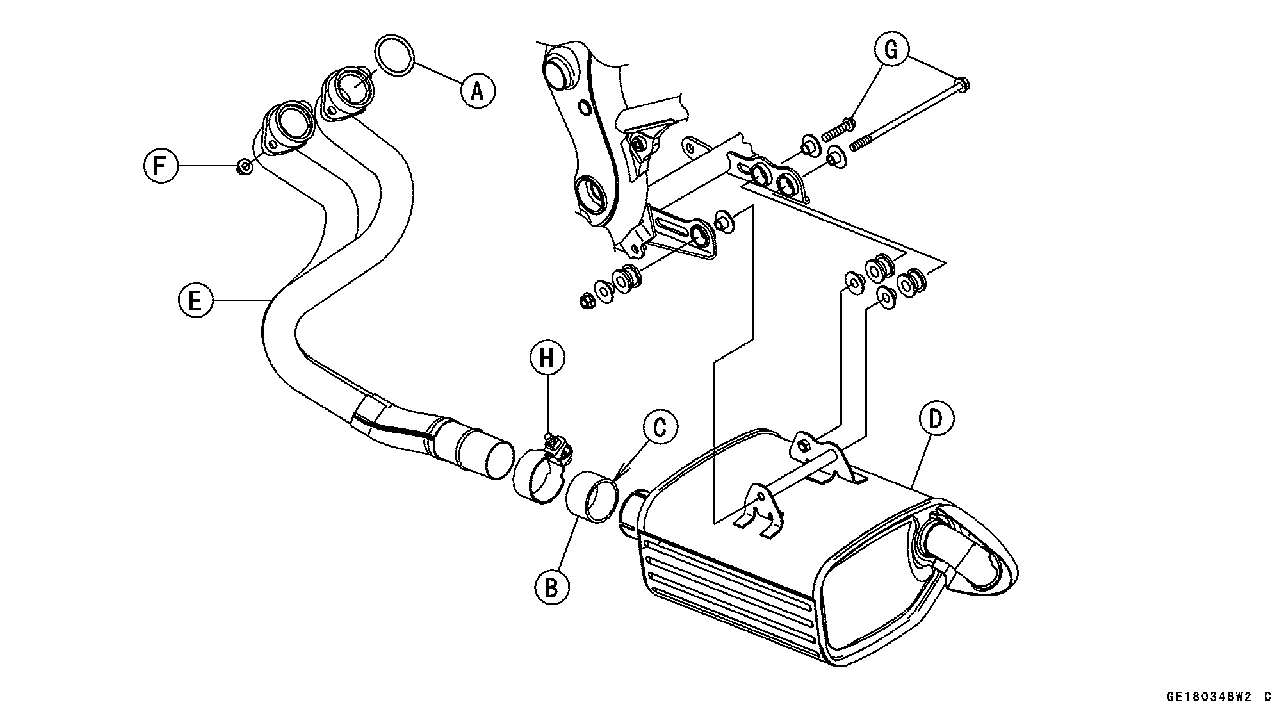

Muffler Body Removal

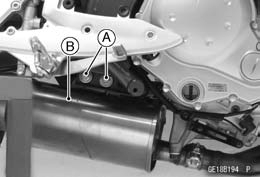

• Remove: Right Frame Cover (see Frame Cover Removal in the Frame chapter) • Remove the bolts and lift up the right footpeg stay [A].

• Remove: Lower Fairings (see Lower Fairing Removal in the Frame chapter) Center Fairings (see Center Fairing Removal in the Frame chapter) Muffler Body Clamp Bolt [A] Exhaust Pipe Manifold Holder Nuts [B] Exhaust Pipe [C] Gaskets

Muffler Body and Exhaust Pipe Installation • Replace the exhaust pipe gaskets [A] and muffler body connection gasket [B] with new ones and install them. ○Install the muffler body connection gasket until it is bot- tomed so that the chamfer side [C] feces muffler body [D]. • Install: Muffler Body Exhaust Pipe [E] • Tighten: Torque - Exhaust Pipe Manifold Holder Nut [F]: 17 N·m (1.7 kgf·m, 12 ft·lb) Muffler Body Mounting Bolts (Front and Rear) [G]: 20 N·m (2.0 kgf·m, 15 ft·lb) • Tighten the muffler body clamp bolt [H]. ○Install the muffler body clamp bolt as shown.

• Thoroughly warm up the engine, wait until the engine cools down, and retighten all the bolts and nuts.

Clutch Table of Contents Exploded View........................................................................................................................ 6-2 Specifications......................................................................................................................... 6-4 Special Tool and Sealant........................................................................................................ 6-5 Clutch Lever and Cable.......................................................................................................... 6-6 Clutch Lever Free Play Inspection.................................................................................... 6-6 Clutch Lever Free Play Adjustment.................................................................................. 6-6 Clutch Cable Removal...................................................................................................... 6-6 Clutch Cable Installation................................................................................................... 6-6 Clutch Cable Lubrication................................................................................................... 6-6 Clutch Lever Installation.................................................................................................... 6-7 Clutch Lever Adjustment................................................................................................... 6-7 6 Clutch Cover........................................................................................................................... 6-8 Clutch Cover Removal...................................................................................................... 6-8 Clutch Cover Installation................................................................................................... 6-8 Release Shaft Removal.................................................................................................... 6-9 Release Shaft Installation................................................................................................. 6-9 Clutch Cover Disassembly................................................................................................ 6-9 Clutch Cover Assembly..................................................................................................... 6-10 Clutch..................................................................................................................................... 6-11 Clutch Removal................................................................................................................. 6-11 Clutch Installation.............................................................................................................. 6-11 Clutch Plate, Wear, Damage Inspection........................................................................... 6-13 Clutch Plate Warp Inspection............................................................................................ 6-14 Clutch Spring Free Length Measurement......................................................................... 6-14 Clutch Housing Finger Inspection..................................................................................... 6-14 Clutch Housing Spline Inspection..................................................................................... 6-14

CL: Apply cable lubricant. EO: Apply engine oil. G: Apply grease. HG: Apply high-temperature grease. L: Apply a non-permanent locking agent. Lh: Left-hand threads M: Apply molybdenum disulfide grease. R: Replacement Parts S: Follow the specified tightening sequence. W: Apply water.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Последнее изменение этой страницы: 2016-08-10; просмотров: 434; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 18.118.184.36 (0.009 с.) |

Piston Wear

Piston Wear If the measurement is under service limit, replace the pis- ton.

If the measurement is under service limit, replace the pis- ton. Piston Ring, Piston Ring Groove Wear

Piston Ring, Piston Ring Groove Wear Piston Ring Groove Width

Piston Ring Groove Width Piston Ring Thickness

Piston Ring Thickness Piston Ring End Gap

Piston Ring End Gap • Be sure to install the O-rings [A].

• Be sure to install the O-rings [A].

Muffler

Muffler

• Remove the muffler body mounting bolts [A] and nut, and pull the muffler body [B] backward.

• Remove the muffler body mounting bolts [A] and nut, and pull the muffler body [B] backward. Exhaust Pipe Removal

Exhaust Pipe Removal

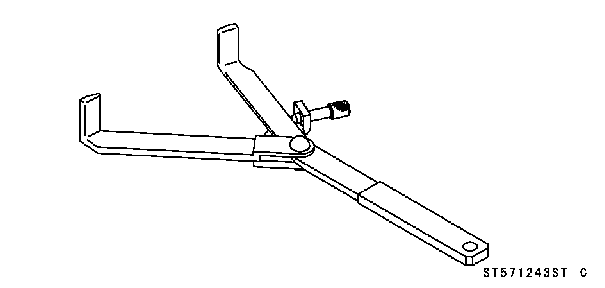

Clutch Holder: 57001-1243

Clutch Holder: 57001-1243