Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Service Limit: 7.3 mm (0.287 in.)Содержание книги

Поиск на нашем сайте

worn dogs or dog holes.

Ball and Needle Bearing Replacement

• Using a press or puller, remove the ball bearing and/or needle bearings. NOTE ○In the absence of the above mentioned tools, satisfac- tory results may be obtained by heating the case to ap- proximately 93°C (200°F) max., and tapping the bearing in or out.

• Using a press and the bearing driver set [A], install the

○The new needle bearings must be pressed into the crankcase so that the end is flush with the end of the hole. Special Tool - Bearing Driver Set: 57001-1129 Ball and Needle Bearing Wear

• Check the ball bearings. ○Since the ball bearings are made to extremely close toler- ances, the wear must be judged by feel rather than mea- surement. Clean each bearing in a high-flash point sol- vent, dry it (do not spin the bearing while it is dry), and oil it with engine oil.

rough spots, replace it. • Check the needle bearings. ○The rollers in a needle bearing normally wear very little, and wear is difficult to measure. Instead of measuring, inspect the bearing for abrasion, color change, or other damage.

Oil Seal Inspection • Inspect the oil seals.

that the rubber has deteriorated), hardened or otherwise damaged.

Wheels/Tires Table of Contents Exploded View........................................................................................................................ 10-2 Specifications......................................................................................................................... 10-4 Special Tools.......................................................................................................................... 10-5 Wheels (Rims)........................................................................................................................ 10-6 Front Wheel Removal....................................................................................................... 10-6 Front Wheel Installation.................................................................................................... 10-6 Rear Wheel Removal........................................................................................................ 10-8 Rear Wheel Installation..................................................................................................... 10-8 Wheel Inspection...................................................................................................................... 10-10 Axle Inspection......................................................................................................................... 10-10 Balance Inspection................................................................................................................... 10-11 Balance Adjustment................................................................................................................. 10-11 Balance Weight Removal........................................................................................................ 10-11 Balance Weight Installation...................................................................................................... 10-11 Tires............................................................................................................................................... 10-13 Air Pressure Inspection/Adjustment......................................................................................... 10-13 Tire Inspection.......................................................................................................................... 10-13 Tire Removal........................................................................................................................... 10-13 Tire Repair............................................................................................................................... 10-15 Hub Bearing................................................................................................................................... 10-16 Hub Bearing Removal.............................................................................................................. 10-16 Hub Bearing Installation........................................................................................................... 10-16 Hub Bearing Inspection............................................................................................................ 10-16 Hub Bearing Lubrication........................................................................................................... 10-17

4. Caliper Bracket (EX650B Models) G: Apply grease. HG: Apply high-temperature grease. R: Replacement Parts WL: Apply soap and water solution or rubber lubricant.

Bearing Remover Shaft,

Jack Attachment: 57001-1608

57001-1293

Front Wheel Removal

Brake Caliper Mounting Bolts [A] Front Brake Calipers [B]

Axle Clamp Bolt [A] • Remove the front axle [B].

• Remove the lower fairings (see Lower Fairing Removal in the Frame chapter). • Raise the front wheel off the ground with jack. Special Tools - Jack: 57001-1238 Jack Attachment: 57001-1608

• Pull out the axle to the right and drop the front wheel out of the forks.

NOTE ○The direction of the wheel rotation [A] is shown by an arrow [B] on the wheel spoke. • Check the wheel rotation mark on the front wheel and install it.

• Apply high-temperature grease to the grease seal lips.

• Insert the front axle, and tighten the axle. Torque - Front Axle: 108 N·m (11.0 kgf·m, 80 ft·lb) • Before tightening the axle clamp bolt on the right front fork leg, pump the front fork up and down 4 or 5 times to allow the right front fork leg to seat on the front axle. NOTE ○Put a block in front of the front wheel to stop moving.

Torque - Front Axle Clamp Bolt: 34 N·m (3.5 kgf·m, 25 ft·lb) • Install the lower fairing (see Lower Fairing Installation in the Frame chapter). • Install the front brake calipers (see Caliper Installation in the Brakes chapter).

• Check the front brake effectiveness (see Brake Operation Inspection in the Periodic Maintenance chapter).

• Raise the rear wheel off the ground with stand [A].

Brake Caliper Mounting Bolts [A] Rear Brake Caliper [B] • Remove the rear wheel rotation sensor from the caliper bracket (see Rear Wheel Rotation Sensor Removal in the Brakes chapter) (EX650B Models).

Axle Nut [B] Washer [C] Axle [D] with Washer

• Apply high-temperature grease to the grease seal lips. • Fit the collars [A] on the both sides of the hub.

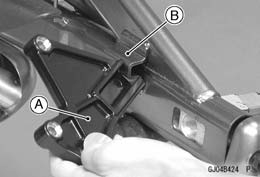

• Install the caliper bracket [A] onto the swingarm stop [B]. • Insert the axle from the right side of the wheel, and tighten the axle nut. Torque - Rear Axle Nut: 108 N·m (11.0 kgf·m, 80 ft·lb)

NOTE ○When inserting the cotter pin, if the slots in the nut do not align with the cotter pin hole in the axle, tighten the nut clockwise [B] up to next alignment. ○It should be within 30°. ○Loosen once and tighten again when the slot goes past the nearest hole.

• Bend the cotter pin [A] over the nut [B]. • Bend the cotter pin [A] over the nut [B].

• Adjust the drive chain slack after installation (see Drive Chain Slack Inspection in the Periodic Maintenance chap- ter). • Install the rear brake caliper (see Caliper Installation in the Brakes chapter). • Install the rear wheel rotation sensor (see Rear Wheel Ro- tation Sensor Installation in the Brakes chapter) (EX650B Models).

• Check the rear brake effectiveness (see Brake Operation Inspection in the Periodic Maintenance chapter).

• Raise the front/rear wheel off the ground with jack.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Последнее изменение этой страницы: 2016-08-10; просмотров: 346; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 3.144.242.149 (0.006 с.) |

Gear Dog and Gear Dog Hole Damage

Gear Dog and Gear Dog Hole Damage • Visually inspect the gear dogs [A] and gear dog holes [B]. Replace any damaged gears or gears with excessively

• Visually inspect the gear dogs [A] and gear dog holes [B]. Replace any damaged gears or gears with excessively new ball bearing until it stops at the bottom of its housing.

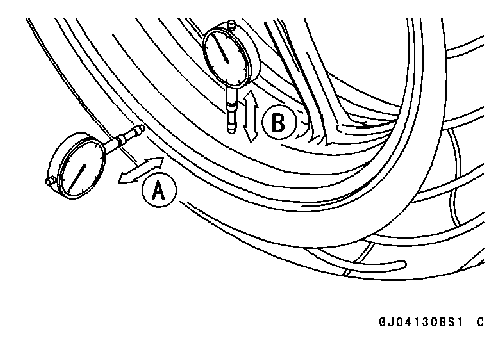

new ball bearing until it stops at the bottom of its housing. ○Spin [A] the bearing by hand to check its condition.

○Spin [A] the bearing by hand to check its condition.

Bearing Driver Set: 57001-1129

Bearing Driver Set: 57001-1129 13: 57001-1377

13: 57001-1377 Jack: 57001-1238

Jack: 57001-1238 Bearing Remover Head,

Bearing Remover Head,

• Remove:

• Remove: • Loosen:

• Loosen: Front Wheel Installation

Front Wheel Installation • Fit the collars [A] on the both sides of the hub.

• Fit the collars [A] on the both sides of the hub. • Tighten the axle clamp bolt [A].

• Tighten the axle clamp bolt [A].

Rear Wheel Removal

Rear Wheel Removal • Remove:

• Remove: • Remove: Cotter Pin [A]

• Remove: Cotter Pin [A] • Remove the drive chain [A] from the rear sprocket toward the left.

• Remove the drive chain [A] from the rear sprocket toward the left. Rear Wheel Installation

Rear Wheel Installation • Engage the drive chain with the rear sprocket.

• Engage the drive chain with the rear sprocket. • Insert a new cotter pin [A].

• Insert a new cotter pin [A].

Wheel Inspection

Wheel Inspection