Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

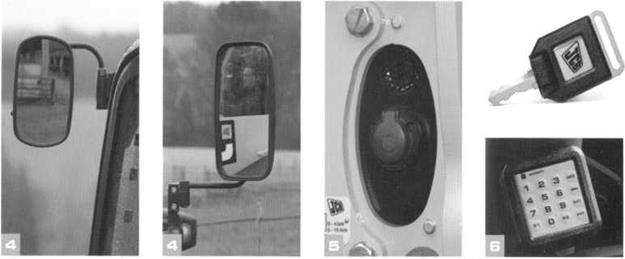

Рисунок 3. A sound investment. Ecomax efficiency. Further efficiency. The strongest contender. Tough boom design. Built-in protection. Durable components. Рисунок 4. A slick operation. Ergonomic controls. Safe and secure. Рисунок 6. Less servicing, more sСодержание книги

Поиск на нашем сайте

Рисунок 3 A SOUND INVESTMENT A JCB construction loadall isn’t just efficient to use – it’s hugely efficient to own and operate too. We’ve designed these machines to give you the maximum possible return on your investment, with great fuel efficiency, unparalleled resale value and low low running costs all part of the package. EcoMAX efficiency 1.The 81 kW and 93 kW EcoMAX engines are fitted with a variable speed cooling fan that automatically reacts to ambient temperature, adjusting fan speed for maximum economy and minimum noise. The new 55 kW high-torque engine provides productivity and maximum efficiency. 2.Because EcoMAX doesn’t use exhaust after-treatment, it doesn’t need costly heat-resistant lube oils or AdBlue; in turn, you save on servicing costs. Efficient Design T4i loadalls use up to 7% les fuel than our Tier 3 models. EcoMAX can be adapted to run on lower-grade fuels, making the Loadalls resalable across different territories, with a corresponding boost to residuals. The Powershift oil level was reduced for 1% energy boost. Further efficiency 3.A JCB Construction Loadall is a great asset in so many respect, not least financially – huge global demand, plus legendary productivity, plus superb build quality equals maximum resale value. 4.High back-off brakes on 531-70, 541-70, 535-95 and 533-105 reduce viscous drag during roading and rehandling, which improves fuel economy by up to 2%. JCB’s Loadall security system is Thatcham-approved (depending on territory), which means you could benefit from lower insurance premiums. THE STRONGEST CONTENDER In order to be truly efficient, our construction loadalls are designed to provide you with maximum uptime. To do that, we build our machines to as tough as possible, using top quality components and innovative manufacturing processes. This, in turn, ensures maximum service life. Tough boom design 1. For ultimate strength and durability, we’ve built in large boom overlaps of more than 1.0m on all of our macines. 2. Hoses are routed through the boom for maximum protection. Built-in protection 3. Bonnets on Construction Loadalls are protected from damage by being side-mounted on the chassis and recessed. 4. Our Construction Loadalls have fold-up rear lights that can be kept clear and well protected from on-site damage. 5. Opt for front and top screen roof guards for added protection from falling objects. 6. Heavy-duty axle feet help a Construction Loadall to absorb the stresses generated during material rehandling applications. To protect our Construction Loadalls from corrosion over the long term, we dip the cab in electrophoretic alloy before painting it.

Durable components Рисунок 4 7. The new Construction Loadall range’s stringent testing programme has included prolonged high stress loading of the chassis, boom and other key components, as well as cold climate testing and repeated transmission use over thousands of cycles. 8. The lift, tilt and extension rams are held in place by keyhole castings for even greater structural integrity. 9. To prove how good our EcoMAX engines are, we’ve tested them for 10, 000 hours in 70 different machines across the toughest applications and environments. 10. The one-piece fully welded chassis maximises strength and minimises weight. 11. At JCB, we make our own hydraulic cylinders, cabs, axles, transmissions and engines – all designed to work in perfect harmony for optimum reliability.

A SLICK OPERATION For a machine to provide maximum efficiency, it needs to be intuitive and comfortable to operate. With that in mind, we’ve designed the new Construction Loadall range to provide the most ergonomic operator environment possible. So you get the most out of your machine and your operator. Ergonomic controls 1. Simple to use twin manual levers and one manual auxiliary with optional single lever joystick. 2. Backlit switches are crystal clear, even in the dark. 3. New instruments and a hi-res TFT screen form an intuitive automotive- style layout. 4. To create the perfect driving position, opt for the easily adjustable tilting telescoping steering column. servo joystick for the fast and precise control (optional on a 535-140/535- 125). 9. The exterior top door slam latch is new – you can now close the upper door from outside and hold the door ajar. SAFE AND SECURE A job construction loadall can save more than just time and money – it can save itself and its operator from potentially dangerous situations. We equip our loadalls with stringent safety measures to protect from accidents, as well as effective security technology to guard against theft.

Рисунок 6 1. For quick, easy and safe access, JCB Construction Loadalls have a three – point access and two cab steps. 2. Hose burst check valves on the rams prevent collapse if a hose fails. 3. A JCB Construction Loadall has excellent rearward and off-side visibility, courtesy of a low boom and bonnet profile and low boom pivot. 4. A JCB Loadall comes equipped with a full set of side and rear view mirrors for all round visibility and safety complience. 5. For extra safety, a reverse alarm is standard-fit on all Construction Loadalls. 6. JCB factory-fit immobilisers, can either be activated by a unique key or optional push button PIN system, that automatically arm themselves after a certain period following engine shutdown. Naturally, you want your Construction Loadall to spend as much time as possible at work, not being worked on. Which is why JCB Loadalls have long service intervals; and, when maintenance does need to be carried out, you’ll find our machines are easy and quick to sevice. 1. Most Tier 4i engines use a Diesel Particulate Filter (DPF). EcoMAX doesn’t. That means no worrying about loss of productivity during the regeneration process and potential extra expense in replacing DPF’s. All daily checks, greasing and serviceable components can be accessed at ground level. 2. You can access a Construction Loadall’s battery easily (and without specialist tools) via a lockable cover that’s opened with the ignition key. 3. The diesel tank is also easy to get to, and can be filled from ground level. For protection from dirty fuel, there’s an integral pre-filter in the filler neck. 4. A dry lubricant system means a Loadall’s wear pads are extremely durable, with service intervals of 500 hours. 5. The filters on a Loadall (engine oil, hydraulic oil and fuel) are centrally located for fast, easy servicing.

|

||||

|

Последнее изменение этой страницы: 2024-06-27; просмотров: 6; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 3.145.90.26 (0.006 с.) |

,,

,,