Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Types of technological communications between operators.Содержание книги

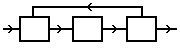

Поиск на нашем сайте In case of all complexity of CTS there are standard connections of the operators among themselves uniting them in the single scheme. Treat them: consecutive connection, parallel connection, consecutive and bypass (bypass) connection and recirculation connection. There is also a kind of the difficult connections uniting several types of elementary connections at the same time. Consecutive connection:

Consecutive connection is the main connection of technological operators among themselves. At this connection all technological stream leaving the CTS previous element completely arrives on the subsequent CTS element, and each element passes a stream only once. Parallel connection:

At parallel connection, the technological stream is divided into several streams which arrive on the CTS various elements, and each device passes a stream only once. The streams leaving elements can unite in one stream, and can leave separately. Consecutive and bypass (bypass) connection:

At consecutive and bypass (bypass) connection passes through a number of consistently connected CTS elements only a part of a stream, and other part bypasses a part of devices, and then connects to a part of the stream which has passed through the CTS elements. Recirculation connection:

Recirculation connection is characterized by existence of the reverse technological flow in system sequentially of connected elements which connects an output of one of the subsequent elements to an input of one of the previous elements. CTS with use of this communication are characterized by recirculation coefficient, i.e. the relation of a recirculating flow to summary (the coefficient is always less than unit). It is necessary to consider that in case of synthesis and optimization of CTS usually it is required to consider rather large number of versions of the diagrams differing in technological topology. To reduce this quantity, and, therefore, helps to spare time and money along with an intuition of the developer, his ability to beforehand estimate effect which is possible for expecting in case of different types of connections between the CTS elements. The stage of the reactors of ideal mixing (RIM) representing a row of sequentially connected reactors owing to change of a hydrodynamic situation will approach the reactor of ideal extrusion (RIE). Thus, changeover one RICE on a stage RICE gives the positive effect. Changeover of one RIV by a stage of RIV doesn't give any effect, however if length of RIV is required rather big, happens more expediently (from the point of view of more compact design of the equipment) to replace one big reactor with a stage of smaller reactors. · replacement one RICE on the RICE cascade, i.e. consistently connected devices (without change of the general time of contact), allows to reach bigger extent of transformation due to change of a hydrodynamic situation and to reduce the constructive size of each reactor. Replacement of one RIV by the RIV cascade allows to reduce the constructive size of each reactor only; · replacement of one RIV or RICE by a number in parallel of the working reactors does not reduce overall effectiveness, but reduces the constructive sizes in parallel of the working reactors; · parallel connection of the additional device allows to increase loading on raw materials at preservation of invariable extent of transformation or, perhaps, to reach higher extent of transformation (without change of speed of supply of raw materials) due to increase in time of stay; · consecutive connection apply when it is necessary to carry out chemical transformation into several stages for endo-or exothermic reactions (especially reversible) proceeding in adiabatic reactors since allows to maintain optimum temperature at each stage (catalytic the reactor, for example, oxidations of SO2 in SO3 or ammonia synthesis); · consecutive connection is applied when it is necessary to carry out technological process with allocation of any component after each stage (for example, in the multistage air compressor after each step of compression there is a cooling of gas and release of drop moisture); · parallel connection is applied when it is necessary to distribute optimum loading between in parallel the working lines differing on productivity, for example, owing to falling of activity of the catalyst, pollution of a heatexchange surface and so forth; • parallel connection is applied when it is necessary to increase reliability of production and to provide a possibility of its work with the minimum performance without decrease in overall performance of the equipment (in case of need, parallel lines can be disconnected on economic purposes or for repair); • in case of bypass connection owing to reduction of the flow going via the reactor time of stay in the reactor increases and extent of transformation of raw materials into products increases (in the reactor); • bypass connection is applied when designing reactors to carrying out reversible exothermic reactions by mixture of a "hot" flow after the reactor with a "cold" bypass flow that allows to reach high extent of transformation and optimum temperatures and therefore high speeds of chemical reactions (catalytic the reactor, for example, oxidations of SO2 in SO3 or ammonia synthesis); • recirculation is applied in cases when it is necessary to increase efficiency of use of raw materials and the equipment due to increase in time of stay in the recirculated devices without change of the sizes of the equipment and a hydrodynamic situation, i.e.; • recirculation allows to reach the maximum use of raw materials (especially for reversible reactions) and to increase process speed due to increase in concentration of initial reagents which is reached in case of allocation of a target product on the line of recycling and return of initial reagents to process "head" (for example, an ammonia synthesis cycle); • recirculation allows to reduce completeness of course of collateral chemical reactions by means of raw materials dilution by the reaction products arriving in process "head" through recycling. As it was specified, data of heuristics belong to reactors, i.e. it is possible to constitute similar lists эвристик for other CTS elements. Besides, the list эвристик for reactors can be expanded for the account heuristics, which are a consequence stated above.

Test questions 1. Types of technological communications between operators. 2. What main technological operators, their features exist. 3. What auxiliary technological operators, their features exist.

|

||

|

Последнее изменение этой страницы: 2017-02-07; просмотров: 292; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 216.73.216.102 (0.008 с.) |