Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Technological Processes of Metal Cold TreatmentСодержание книги

Поиск на нашем сайте Apart from thermal treatment, metals and alloys are very often subject to mechanical processing. In these techniques a metallic piece is subject to external pressures to induce deformation under which the material acquires a desired shape. During cold working the most common forming techniques are realized: forging, rolling, extrusion, stamping, drawing and squeezing. All these techniques are referred to as treatment of metals by pressure. Forging is the working of metals performed by means of hammer blows or under pressure of a press. Forging enhances the mechanical properties of metal and improves its structure. Forging operations can be hand and machine operations. Hand forging is carried out on anvils with the aid of hand forging tools. Machine forging is done under forge hammers or presses. Depending on the methods of the production of forged articles, forging processes are classified as hammers and die-forging (stamping). In hammer forging the metal shape is changed by pressing the metal between the dies of a hammer or a press. It should be mentioned that forging operations may also be hot. Rolling is accomplished by rolling-mill. A mill consists of a number of stands that may be reverse or non-reverse. Roll forming is a continuous bending operation in which sheet or strip metal is gradually formed in tandem sets of rollers until the desired cross-sectional configuration is obtained. Roll forming is ideal for producing parts with long lengths or in large quantities. Rolling comprises rolling of slabs, blooms, sheets or plates, strips or rods, tubes, rails, angles and many other kinds of finished product of different thickness and different shapes from an ingot or a billet.

There are three kinds of rolling: cold, hot and special tube rolling. A particular group represents various types of mills, including hot and cold drawing mills. The drawing operation is very similar to the forming operation except that the drawing undergoes severe plastic deformation and the material of the part extends around the sides. A metal cup is an example of the difference between formed and drawn. The bottom of the cup was formed while the sides were drawn.

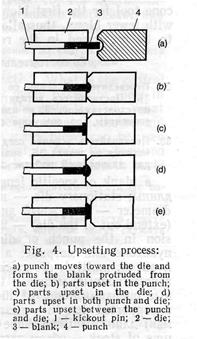

Upsetting is a cold forming operation for reshaping metal by plastic flow. Upsetting is accomplished by inserting a blank of specific length into a stationary die. A punch moves towards the die, contacts the protruded portion of the blank and upsets it.

Exercise 1. Translate the word combinations with Gerund, Participle I and verbal noun: mechanical processing, cold working, forming technique, forging operation, working of metal, hand forging, forging tools, machine forging, forging processes, hammer forging, pressing the metal, rolling mill, cold rolling, tube rolling, drawing mill, drawing operation, forming operation, deforming blank, roll forming, bending operation, producing parts, wire pulling, wire making die, pulling a rod.

Exercise 2. Translate the word combinations with Participle II into Russian: desired shape, performed working, forged articles, desired configuration, finished product, formed part, drawn part, extruded parts, protruded blank, lubricated material, reduced size. Exercise 3 . Complete the sentences: 1. Metals and alloys are very often subject to … 2. All forming techniques are treatment of metals by … 3. Forging working of metals is fulfilled under pressure of …

4. Forging enhances … 5. In hammer forging the metal shape is changed by… 6. Extrusion is the act of deforming blanks of metal called … 7. Upsetting is a cold forming operation for … 8. Upsetting is being done by inserting a blank into … 9. Wire pulling is realized by … 10. For pulling a wire several dies are used to … Exercise 4 . Insert the proper words into the sentences: 1. Metals and (сплавы) are often (подвергаются) to mechanical processing. 2. (Ковка) is performed by means of (ударов молота). 3. Forging (усиливает) the mechanical (свойства) of metals. 4. (Прокатный стан) consists of a number of (клетей). 5. Rolling (включает в себя) rolling of (плит), (стальных болванок) etc. 6. Rolling is making products of different (толщины) and (формы). 7. Roll forming is a continuous (гибочная операция). 8. (Выдавливание) and (сжатие) are severe deforming (заготовок). 9. By (при высадке) (штамп) contacts (заготовки) and upsets it. 10. (Вытягивание проволоки) is realized by (пресс-формами).

Exercise 5 . Choose synonyms to the Russian word: 1. обработка а) processing c) treatment b) machining d) dealing;

2. производство a) performance c) production b) manufacture d) business;

3. тепловой a) warn c) heat b) hot d) thermal;

4. обработка а) pressure c) relieving давлением b) squeezing d) pressing;

5. заготовка а) bloom c) billet b) ingot; d) blank;

6. подвергать a) to induce c) to subject to чему-либо b) to undergo d) to enhance.

Speaking: Exercise 6 . Give the summary of the text, using key vocabulary and tell about: a) what is mechanical processing; b) the influence of forging the mechanical properties of metals; c) the technique of forging; d) what products can be made by rolling; e) wire pulling. Checklist for Section VIII: 1. How is Participle II translated into Russian as an attribute in word combinations? 2. What verbal forms are derived with the suffix -ing? 3. What are the processes of metal cold treatment? 4. What properties are acquired by metals under pressure processing? Section IX

|

||

|

Последнее изменение этой страницы: 2016-12-12; просмотров: 668; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 216.73.216.214 (0.008 с.) |

Extrusion and squeezing are the acts of severely deforming blanks of metal called slugs into finished parts such as an aluminum I-beam. Extrusion dies use extremely high pressure from the punch to squeeze the metal out into the desired form. The difference between cold forming and extrusion is that the extruded parts do not take shape of the punch.

Extrusion and squeezing are the acts of severely deforming blanks of metal called slugs into finished parts such as an aluminum I-beam. Extrusion dies use extremely high pressure from the punch to squeeze the metal out into the desired form. The difference between cold forming and extrusion is that the extruded parts do not take shape of the punch. Wire pulling is realized by wire making dies having a hole through the middle of them. A wire or rod of steel, copper, or other metals or alloy, enters into one side, is lubricated and reduced in size. The wire should never actually come in contact with the die. For pulling a substantial rod down to a fine wire a series of several dies is used to obtain progressive reduction of diameter in stages.

Wire pulling is realized by wire making dies having a hole through the middle of them. A wire or rod of steel, copper, or other metals or alloy, enters into one side, is lubricated and reduced in size. The wire should never actually come in contact with the die. For pulling a substantial rod down to a fine wire a series of several dies is used to obtain progressive reduction of diameter in stages.