Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

This phenomenon, relating to ponds and lakes, is reversible, as it supplements the ground water table during periods of drought and supplements sustaining flows during the wet season.Содержание книги

Поиск на нашем сайте

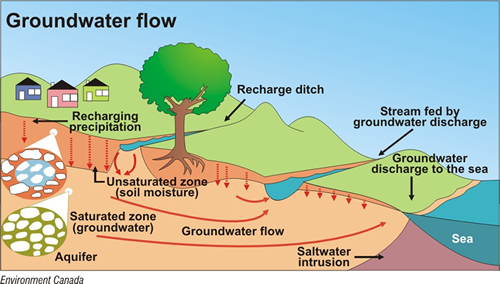

11. Discuss in the group the pictures below: 1)

2)

UNIT 6 SEWAGE SYSTEMS 1. Remember the following words: Sewage - сточные воды Domestic sewage - коммунально-бытовые сточные воды Water service – водоснабжение Sewerage – канализация To convey – переправлять, передавать Treatment plant - 1) очистная станция; очистное сооружение 2) водоочистная станция Harmful - вредный Sludge – 1) осадок; отстой; шлам, 2) осадок в резервуаре со сточными водами, 3) густая грязь; ил Disinfecting - дезинфицирующий Septic tank – септический резервуар Solid wastes - твердые отходы Gray water - сточные воды Breakdown – авария, поломка To dispose - помещать, размещать, располагать, распределять To decant - фильтровать; отделять осадок; декантировать (отделять твердые вещества от жидких, или жидкие от жидких, путем сливания жидкости) Leach - выщелачивание To seep - просачиваться; проникать, протекать Well - водоем, колодец Surface waters - поверхностные воды Environmental standards - экологические стандарты Sanitary waste - domestic waste (DW) - бытовые отходы Drainage system - канализационная сеть; система сбора сточных вод; дренажная система Discharge - вытекание, сток, слив; дренаж Plumbing - водопровод; водопроводно-канализационная сеть, водопроводное дело, прокладка труб Fluctuation - колебание; неустойчивость Sewer gas - газ сточных вод 2. Read and translate the text below:

Text 6 A Sewage Systems In areas where centralized sewage-handling systems are available, sewage is usually provided as a bundled package with domestic water service. Sewage is conveyed most often by open channel gravity flow, to sewage treatment plants. Sewage treatment plants remove harmful materials and sludges, cleaning and disinfecting the water before flushing it back into natural water sources (lakes, rivers or sea). In rural locations where a sewer connection is impractical or unavailable, sewage is often processed with septic tanks. Septic tanks collect and separate solid wastes from the waste water, also known as gray water. Septic tanks are charged with anaerobic bacteria to breakdown the waste solids to form a sludge, which settles to the bottom of the septic tank. Over time, sludge will build up in the bottom of the septic tank and must be removed and disposed of to keep the septic tank operating properly. Usually, local contractors can be located that are specifically licensed to pump out septic tanks and dispose of the waste sludge. The gray water waste is decanted off the top of the septic tank and is piped to the leaching field, which includes perforated lateral lines that allow the wastewater to seep into the soil. A septic tank and leach field is an engineered system. Soil tests are required to determine the percolation rate of the soil, the rate at which the ground will accept the wastewater. Extreme caution is required to keep the septic leachate away from water wells and surface waters. Usually, local health officials review the engineering designs and inspect the installations of septic tanks and leach fields to insure that health and environmental standards are maintained. Sanitary Waste. Domestic Waste (DW) refers to specific types of building interior waste and drainage systems. Wastes, or soils, are generally any sort of mixture of solid and liquid waste introduced into the building waste and drain system like the discharges from water closets, food disposers and dishwashers. Drainage refers to nominally clear water waste like condensation or discharge from plumbing fixtures that produce generally clear but soapy discharges like lavatories, showers and washing machines. The waste pipes and drains convey soils, wastes and clear water wastes out of the building into a sewer or septic system. The vent system compliments the waste and drainage systems by solving some hydraulic flow problems, eliminates pressure fluctuations within the wastewater system, protects fixture traps seals from syphonage, and vents sewer gases to the outdoors.

TEXT EXERCISES

3. Find Russian equivalents in the text

Centralized sewage-handling systems; bundled package; domestic water service; sewage treatment plants; harmful materials and sludges; septic tank; gray water; to seep into the soil; leach fields; waste and drainage systems

4. Fill in the necessary word:

1. In areas where ___ sewage-handling systems are available, ___ is usually provided as a bundled package with domestic ___ service. 2. Sewage ___ plants remove ___ materials and sludges, cleaning and disinfecting the ___ before flushing it back into natural water ___ (lakes, rivers or sea). 3. In ___ locations where a sewer connection is impractical or ___, sewage is often processed with ___ tanks. 4. Septic tanks collect and separate solid wastes from the waste water, also known as gray water. 5. A septic ___ and leach ___ is an engineered system. 6. Soil tests are required to ___ the percolation rate of the soil, the rate at which the ground will ___ the wastewater. 7. Usually, local ___ officials review the engineering designs and ___ the installations of septic tanks and leach fields to insure that health and ___ standards are maintained.

5. Read the text about sewerage system in Melbourne. Discuss the information you've learned from the text with your group-mates:

Sewerage System – How It Works

Our sewerage system removes and treats over 320,000 million litres of sewage each year – enough to fill 128,000 Olympic-sized swimming pools. So what happens when you flush the toilet or pour something down the sink?

Sewage from your bathroom, toilet, kitchen and laundry enters the sewerage system through a network of underground pipes. Melbourne’s three retail water companies look after these pipes, which are located along property boundaries and streets. Sewage generated by commercial or industrial businesses is called trade waste. These businesses need their water retailer’s permission to discharge trade waste into the sewerage system, as it is usually more contaminated than household waste. Trade waste can contain chemicals, metals, fats or detergents that may increase the risk of environmental damage and the cost of sewage treatment. Sewage flows to larger sewers. The retailers’ pipes eventually join up with tunnels and large pipes, called trunk sewers, which we manage. These transport most of Melbourne’s sewage to either the Eastern or Western treatment plants – a journey which can take up to 12 hours. The sewers slope downwards so sewage can use gravity to slowly flow along. Eventually pumping stations bring the sewage up to ground level for treatment, or to allow it to continue using gravity on its journey through the sewerage system. Sewage enters treatment plants. Our two treatment plants process sewage before it can be supplied as recycled water or released into the environment. This process takes up to 30-35 days. Each plant has a different method of treating sewage. The Western Treatment Plant uses a series of large ponds, called lagoons, to treat sewage to either a Class A or Class C recycled water standard. Sewage flows slowly through these ponds, gradually becoming cleaner as bacteria break down the organic material in the water. This process usually takes around 30 to 35 days. There are a number of lagoon systems at the plant. These are made up of large ponds, of which the largest can hold around 600 million litres of water. How the modern lagoon systems work 1. Raw sewage flows into the lagoon systems at the Western Treatment Plant 2. Massive lagoon covers suppress the odour, halve greenhouse gas emissions and capture methane gas 3. The methane gas is used to produce electricity 4. Aerators dissolve oxygen into the wastewater 5. The activated sludge system removes nitrogen from the wastewater 6. After 30 to 35 days in the lagoon system, the treated effluent is either recycled or is discharged to Port Phillip Bay, under strict EPA Victoria licence requirements 7. Recycled water is supplied to a range of customers, including our Hoppers Crossing Pumping Station, and used at the plant for irrigation and conservation Types of ponds and bacteria Each type of pond produces different bacteria, which we need to break down the sewage.

Sewage at the Eastern Treatment Plant goes through three treatment stages to produce Class A recycled water.

Primary treatment. Primary treatment includes: · filtering out large objects like cotton buds, rags and other rubbish, using fine screens · aerating the sewage to remove finer particles like grit and sand; · sedimentation, where heavy items sink to the bottom forming a layer called sludge – the settled sludge and floating debris is pumped to larger tanks, known as digesters, where it is broken down by bacteria Secondary treatment. In secondary treatment, different types of bacteria exist side by side in aerobic (with oxygen) and anoxic (without oxygen) environments, breaking down organic material and removing nutrients in the plant's aeration tanks. The water then passes through sedimentation tanks where more sludge settles to the bottom to finally produce clear treated water at the top, also known as secondary effluent. The treated secondary effluent flows to large holding ponds before it enters the tertiary treatment stage of the plant. Tertiary treatment. · In 2012, the plant was upgraded to treat effluent to an advanced tertiary standard. This process adds several additional steps including: · ozone and UV disinfection · biological filtration to reduce ammonia, oil and grease, foam, litter and solids · chlorination The treated water is then recycled or discharged to the marine environment at Boags Rocks, under strict EPA Victoria licence requirements.

from: Melbourne Water. http://www.melbournewater.com.au/whatwedo/treatsewage/seweragesystem/pages/how-our-sewage-system-works.aspx

6. Read and remember the definitions of disinfection:

from Business Dictionary: http://www.businessdictionary.com/definition/disinfection.html:

from Lenntech: http://www.lenntech.com/processes/disinfection/what-is-water-disinfection.htm#ixzz4FcDAPYrU

7. Give written translation of the text below:

Sanitary Sewer Systems. Sanitary sewer collection systems serve over half the people in the United States today. EPA estimates that there are approximately 500,000 miles of publicly owned sanitary sewers with a similar expanse of privately-owned sewer systems. Sanitary sewers were designed and built to carry wastewater from domestic, industrial and commercial sources, but not to carry storm water. Nonetheless, some storm water enters sanitary sewers through cracks, particularly in older lines, and through roof and basement drains. Due to the much smaller volumes of wastewater that pass through sanitary sewer lines compared to combined sewers, sanitary sewer systems use smaller pipes and lower the cost of collecting wastewater. Wastewater Treatment. In 1892, only 27 American cities provided wastewater treatment. Today, more than 16,000 publicly-owned wastewater treatment plants operate in the United States and its territories. The construction of wastewater treatment facilities blossomed in the 1920s and again after the passage of the CWA in 1972 with the availability of grant funding and new requirements calling for minimum levels of treatment. Adequate treatment of wastewater, along with the ability to provide a sufficient supply of clean water, has become a major concern for many communities. Primary Treatment. The initial stage in the treatment of domestic wastewater is known as primary treatment. Coarse solids are removed from the wastewater in the primary stage of treatment. In some treatment plants, primary and secondary stages may be combined into one basic operation. At many wastewater treatment facilities, influent passes through preliminary treatment units before primary and secondary treatment begins. Preliminary Treatment. As wastewater enters a treatment facility, it typically flows through a step called preliminary treatment. A screen removes large floating objects, such as rags, cans, bottles and sticks that may clog pumps, small pipes, and down stream processes. The screens vary from coarse to fine and are constructed with parallel steel or iron bars with openings of about half an inch, while others may be made from mesh screens with much smaller openings. Screens are generally placed in a chamber or channel and inclined towards the flow of the wastewater. The inclined screen allows debris to be caught on the upstream surface of the screen, and allows access for manual or mechanical cleaning. Some plants use devices known as comminutors or barminutors which combine the functions of a screen and a grinder. These devices catch and then cut or shred the heavy solid and floating material. In the process, the pulverized matter remains in the wastewater flow to be removed later in a primary settling tank. Primary Sedimentation. With the screening completed and the grit removed, wastewater still contains dissolved organic and inorganic constituents along with suspended solids. The suspended solids consist of minute particles of matter that can be removed from the wastewater with further treatment such as sedimentation or gravity settling, chemical coagulation, or filtration. Pollutants that are dissolved or are very fine and remain suspended in the wastewater are not removed effectively by gravity settling. When the wastewater enters a sedimentation tank, it slows down and the suspended solids gradually sink to the bottom. This mass of solids is called primary sludge. Various methods have been devised to remove primary sludge from the tanks. Newer plants have some type of mechanical equipment to remove the settled solids from sedimentation tanks. Some plants remove solids continuously while others do so at intervals. Secondary Treatment. After the wastewater has been through Primary Treatment processes, it flows into the next stage of treatment called secondary. Secondary treatment processes can remove up to 90 percent of the organic matter in wastewater by using biological treatment processes.

8. Read the Text 12 from the Supplementary Reading to learn about DWV system.

9. Read the Text 13 from the Supplementary Reading to learn about Methods of Secondary Treatment

10. Remember the words and word expressions below. They will help you to understand the text below:

|

||||||||||||||||||||||||||||

|

Последнее изменение этой страницы: 2016-12-09; просмотров: 602; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 52.15.241.87 (0.007 с.) |

Sewage enters the sewerage system.

Sewage enters the sewerage system.