Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Task 3. Read and translate the following text.Содержание книги

Поиск на нашем сайте

BEARINGS. COMPONENTS AND SPECIFICATIONS Rolling-contact bearings are designed to support and locate rotating shafts or parts in machines. They transfer loads between rotating and stationary members and permit relatively free rotation with a minimum of friction. They consist of rolling elements (balls or rollers) between an outer and inner ring. Cages are used to space the rolling elements from each other. Figure 1 illustrates the common terminology used in describing rolling-contact bearings. The inner and outer rings of a rolling-contact bearing are normally made of SAE 52100 steel, hardened to Rockwell C 60 to 67. The rolling-element raceways are accurately ground in the rings to a very fine finish (16 min or less). Rings are available for special purposes in such materials as stainless steel, ceramics, and plastic. These materials are used in applications where corrosion is a problem.

Fig.1 Radial contact bearing terminology. Cages, sometimes called separators or retainers, are used to space the rolling elements from each other. Cages are furnished in a wide variety of materials and construction. Pressed-steel cages, riveted or clinched and filled nylon, are most common. Solid machined cages are used where greater strength or higher speeds are required. They are fabricated from bronze or phenolic-type materials. At high speeds, the phenolic type operates more quietly with a minimum amount of friction. Bearings without cages are referred to as full-complement. A wide variety of rolling-contact bearings are normally manufactured to standard boundary dimensions (bore, outside diameter, width) and tolerances which have been standardized by the AFBMA. All bearing manufacturers conform to these standards, thereby permitting interchangeability. PRINCIPAL STANDARD BEARING TYPES

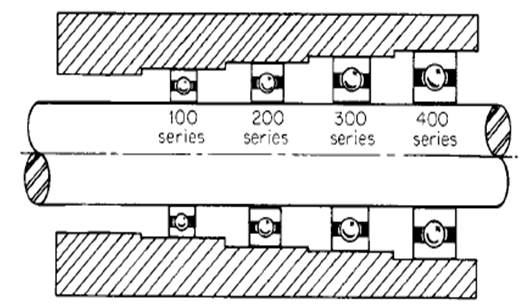

The selection of the type of rolling-contact bearing depends upon many considerations, as evidenced by the numerous types available. Furthermore, each Fig.2 Bearing standard series. basic type of bearing is furnished in several standard ‘‘series’’ as illustrated in Fig.2. Although the bore is the same, the outside diameter, width, and ball size are progressively larger. The result is that a wide range of load-carrying capacity is available for a given size shaft, thus giving designers considerable flexibility in selecting standard-size interchangeable bearings. Some of the more common bearings are illustrated below and their characteristics described briefly.

BEARING CLOSURES Rolling-element bearings are made with a wide variety of closures. Basically, they are open, shielded, or sealed (Figs. 3). Shielded bearings have a small clearance between the stationary shield and rotating ring. This provides reasonable exclusion of dirt without an Fig. 3 Fig. 4 increase in friction. Sealed bearings have a flexible lip (usually synthetic rubber) in contact with the inner ring. Friction is increased, but more effective retention of lubricant and exclusion of dirt is obtained. Seals should not be used to seal a fluid head or at high speeds. NOTES:

Task 4. Answer the following questions: 1) What is rolling-contact bearing? 2) What parts of bearing can you name? 3) What is the main function of a cage in bearing? 4) A wide variety of rolling-contact bearings are normally manufactured to standard boundary dimensions and tolerances, aren't they? 5) What is a closure? Where can it be used? 6) There is a wide variety of closures. Name them. 7) Each basic type of bearing is furnished in several standard ‘‘series’’, isn't it? 8) Sealed bearing has a rigid synthetic lip, hasn't it?

|

||||||||||||||||||||||

|

Последнее изменение этой страницы: 2016-04-08; просмотров: 659; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 18.118.1.100 (0.007 с.) |

That’s how we express agreement and disagreement in English. Study this table.

That’s how we express agreement and disagreement in English. Study this table.