Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Task 12. Complete the following statements from column A with the corresponding terminations from column B.Содержание книги

Поиск на нашем сайте

Task 13. Complete the following training material for graduate engineers using the words in the box. Use each word only once.

Manufacturing techniques evaluation: cutting operations

Cutting options 1) _______: abrasive cutting, removing a kerf of material. Includes cutting with toothed blades and abrasive wheels. 2) _______: use of pressure on smooth-edged blades for guillotining and punching. 3) _______: removal of material across the full diameter of a hole, or using hole-saws for cutting circumferential kerfs. 4) _______: removal of surface layers with multiple cutting wheel passes. 5) _______: using oxy fuel (oxygen + combustible gas, often acetylene)

Task 14. Complete the following definitions using the words or word combinations in the box.

1) A ______ make holes by applying pressure to shear the material. 2) A ______ makes straight cuts by applying pressure to shear the material. 3) A ______ is the width of the saw cut. 4) A ______ has sharp edges for cutting or milling. 5) A ______ has a hard, rough surface for cutting or grinding. 6) A ______ cuts a circular piece to remove an intact core of material.

Task 16. Watch the video file “Tools with Integrated Dampening” about pioneering solution to vibration problems when machining with long slender tools. Write a short report (100-120 words) on a process that is shown. UNIT 5. MOTION CONTROL SYSTEMS OVERVIEW Task 1. Discuss the following questions: a) b) Where are motion control systems used today? Make a list of possible applications of motion control systems. Compare it with those of your groupmates.

Task 2. Look at the picture. Try to give a definitions to all parts of this multiaxis X-Y-Z motion platform.

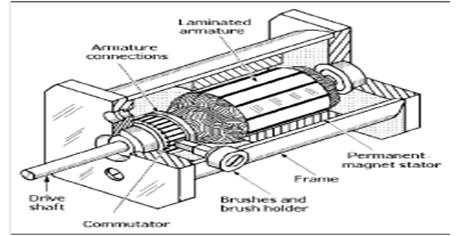

Task 3. Describe the main operation principle of a fractional horsepower permanent-magnet DC servomotor that is shown and get ready for presenting your report at the conference “Innovations in Science and Technology”. Write a plan of your report.

|

|||||||||||||||||||||||||||

|

Последнее изменение этой страницы: 2016-04-08; просмотров: 1462; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 18.217.89.130 (0.008 с.) |

Key factors in determining the most cutting technique are: material characteristics (notably hardness, and thermal and electrical properties), component thickness, component shape and complexity, required edge quality, and production volume. Select cutting options below for a detailed analysis of techniques.

Key factors in determining the most cutting technique are: material characteristics (notably hardness, and thermal and electrical properties), component thickness, component shape and complexity, required edge quality, and production volume. Select cutting options below for a detailed analysis of techniques.

How much do you know about a motion control system?

How much do you know about a motion control system?

Task 4. Listen to the description of motion control systems and try to describe the main principle of it. Give your own example of using motion control systems.

Task 4. Listen to the description of motion control systems and try to describe the main principle of it. Give your own example of using motion control systems.