Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Basic Torque for General FastenersСодержание книги

Поиск на нашем сайте

PERIODIC MAINTENANCE

Specifications

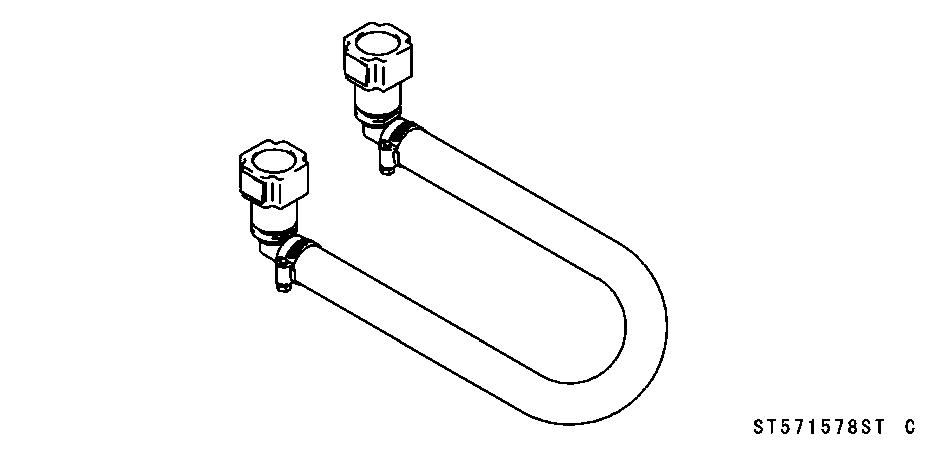

Steering Stem Nut Wrench: 57001-1100

Pilot Screw Adjuster, E: 57001-1603

Oil Filter Wrench: 57001-1249

PERIODIC MAINTENANCE

Periodic Maintenance Procedures

Fuel System (DFI)

Air Cleaner Element Cleaning

NOTE ○In dusty areas, the element should be cleaned more frequently than the recommended interval.

○After riding through rain or on muddily roads, the ele-ment should be cleaned immediately.

If dirt or dust is allowed to pass through into the throttle assy, the throttle may become stuck, possi-bly causing accident.

CAUTION

If dirt gets through into the engine, excessive en-gine wear and possibly engine damage will occur.

•Remove:

Fuel Tank (see Fuel Tank Removal in the Fuel System (DFI) chapter)

Air Switching Valve Hose [A] (Disconnect) Air Cleaner Element Screw [B] Air Cleaner Element [C]

•Remove:

Upper Plastic Holder [A]

Element [B]

NOTE ○The wire screen [A] is fastened with an adhesive for the shaded portion [B]. Do not remove the wire screen.

PERIODIC MAINTENANCE 2-15

Periodic Maintenance Procedures

Clean the element in a well -ventilated area, and make sure that there are no sparks or flame any-where near the working area.

Because of the danger of highly flammable liquids, do not use gasoline or a low-flash point solvent to clean the element.

• Clean the element [A] in a bath of high-flash point solvent, and then dry it with compressed air or by shaking it. • After cleaning, saturate a clean, lint-free towel with SE, SF, or SG class SAE 30 oil and apply the oil to the element by tapping the element outside with the towel.

• Visually check the element for tears or breaks. • Ifment.the element has any tears or breaks, replace the ele-

• Install the element unit [A] with the foam element side (gray) [B] facing down.

Throttle Control System Inspection

• Check that the throttle grip moves smoothly from full open to close [A], and the throttle closes quickly and completely

by the return spring in all steering positions.

•Check the throttle grip free play [A].

Throttle Grip Free Play

Standard: 2 ∼ 3 mm (0.08 ∼ 0.12 in.)

PERIODIC MAINTENANCE

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Последнее изменение этой страницы: 2016-08-10; просмотров: 285; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 3.144.16.40 (0.006 с.) |

WARNING

WARNING

WARNING

WARNING

If the throttle grip doesn’t return properly, check the throt-tle cable routing, grip free play, and cable damage. Then lubricate the throttle cable.

If the throttle grip doesn’t return properly, check the throt-tle cable routing, grip free play, and cable damage. Then lubricate the throttle cable.