Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

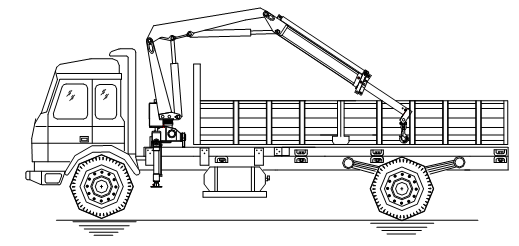

Section 2. Extend and furl the hydraulic craneСодержание книги Поиск на нашем сайте

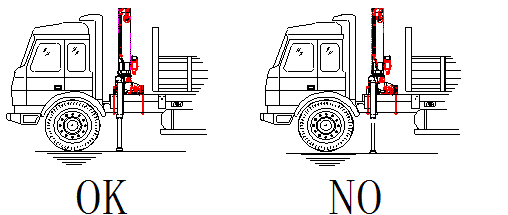

WARNING Јє When stabilize the crane,put out all the activity legs,the leg cylinder and the wheels all touch the earth.

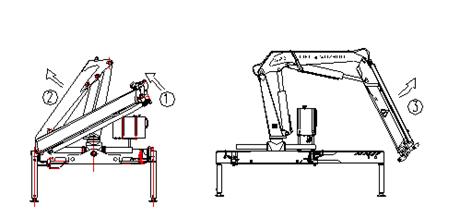

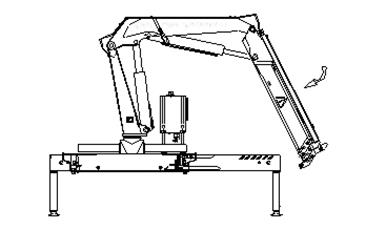

The hydraulic crane spread. WARNING Јє when the hydraulic crane delivery there are A,B two point support,as the follow picture.

(A) (B) A fixed on the fix leg, prevent the leg turntable. WARNING Јєwhen the crane delivery(leave factory),there is a lock, only open the lock, the crane can work, if not the steel of the crane will broken, like the left picture above. B the second knuckle boom cooperate with the turntable, the turntable support the second knuckle boom, prevent the boom go down.

The process of extend the knuckle crane: 1.Make the second knuckle boom absolute furl, let the support point(picture B) open. 2. make the first knuckle extend. 3. extend the second knuckle.

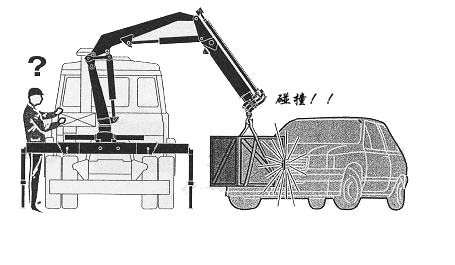

ATTENTION Јє operator must take care of the boom and the rotation unit base.

The telescopic boom operate Јє Before hoisting the goods, the operator need estimate the weight of the goods.(the same as the rated lifting moment) and count the point of fall. When put down the goods, the operate need slowly, exactly, not swing, and carefully prevent bump the truck and the crane.

In order to improve the natural life of the turntable, prevent hoisting the heavy goods turn. Before turn shorten the boom. When hoisting the goods,prevent abruptly stop and begin, this can concussion the hydraulic structure. ATTENTION Јє the telescopic boomЎЇs joy stick is the same one. The furl of the hydraulic crane.

Furl the telescopic boom: absolute furl the telescopic boom. ATTENTION ЈєDo not move when the crane working.

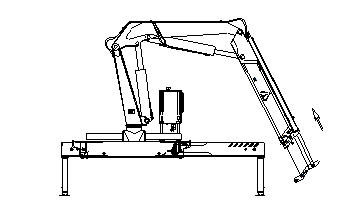

Adjust turntable positionЈєturn turntable until the first knuckle boom level with the fixed leg. WARNING ЈєWhen the first knuckle boom level with the fixed leg. the arrowhead on the turntable and the rotation unit base must uniform.

Furl the second knuckle boomЈєabsolute furl the knuckle boom.

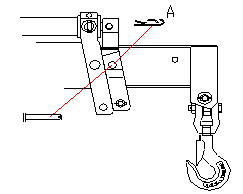

Furl the first knuckle boom: make the firstly knuckle boom slowly down, the firstly head knuckle boom of preventable rotation unit should be fixed on the relative units of fastness supportive legs, refers to left chart as below

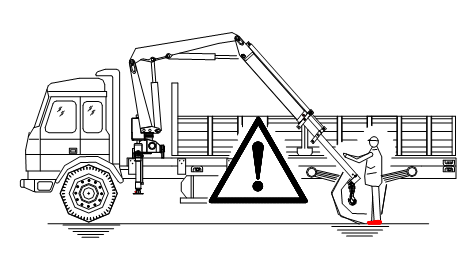

Furl the activity legsЈєopen two of the safety valves on the legs cylinder,operate the leg cylinderЎЇ joy stick, furl the left and right legs cylinder, lock all the safety valves on the legs cylinder(close).then open the lock on the activity legs, then furl it and locked it. WARNING Јє Activity leg must absolutely furl. ATTENTION Јє Make sure the activity absolutely furl, and lock it. CAUTION Јє 1. Hydraulic pump without connection with force equipment after complete work 2. After operation, check the control levers to ensure they are automatically reset. If any lever is not back to its central position, manually reset it to the central position. Use the manual boomЈЁchoose adjunctЈ© Manual boom setting Јє in order setting the manual boomЈthe boom stay as the picture show, so that is easy to operate. WARNING Јє If you want to make the hydraulic crane reach the rated capacity of the hydraulic telescopic boom, the manual telescopic boom will be removed WARNING Јє this course need two people assist.

THE PICTURE AS FOLLOWSЈє

Install the manual telescopic boom and lock it. ATTENTION Јє Ensure to make the spring replaced certainly.

Manual boom back out.

Attention Јє must rememberЈwhen open the lock, the manual boom will slide to one point, so the people need stand outside the manual boom, prevent hurt people.

Crane Service The crane shall be regularly examined and serviced to ensure that parts and components, especially safety devices, are in good condition and function properly. 1.Check the driving circuit connections. Check the entire hydraulic power driving pipes and make sure they are free of leak and distortional deformation.

2.Check the hydraulic oil level Check the oil capacity in the tank, oil level will not high up or low down the max. or the min. marks. Chapter 7. Troubleshooting

Chapter 8. Maintenance

|

||||||||||||||||||||||||||||||||

|

Последнее изменение этой страницы: 2020-11-11; просмотров: 133; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 3.141.27.70 (0.009 с.) |