Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Operation and Maintenance of ManualСодержание книги Поиск на нашем сайте Operation and Maintenance of Manual SQ5Z Crane

XUZHOU BOB-LIFT CONSTRUCTION MACHINERY CO.,LTD.

Copyright: Xuzhou Bob-Lift Construction Machinery Co., Ltd. Manufacture: Xuzhou Bob-Lift Construction Machinery Co., Ltd.

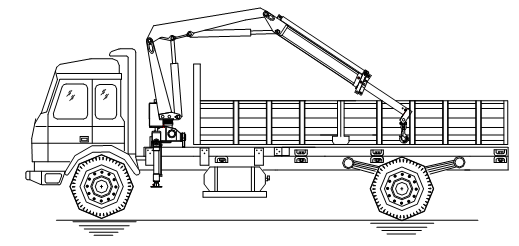

This manual includes eight chapters, Summary of each chapter is described below: Chapter 1. Truck Crane Overview This chapter includes many important whole information about Products, It is good for you to generally realize the Truck Mounted Crane that is our main purpose. Chapter 2.Technical Data This chapter includes all technical data and characteristic index about Truck Crane. Chapter 3. Safety rules and regulation for Truck Crane operation This chapter brings forward all frondose rules and instructions on how to operate the Truck Crane exactly and safely. Chapter 4. Operator Requirements This chapter provides master skills and requirements for operator. Chapter 5.Operation controls This chapter mainly illustrates and demonstrates each operational instructions of Truck Crane. Chapter 6. Truck Crane Operation This chapter mainly instructs each process of usage about Truck Crane. Chapter 7. Troubleshooting This chapter mainly instructs regular faults that may be appeared and the method of remove during the process of usage about Truck Crane. Chapter 8. Maintenance This chapter mainly instructs many conventionally maintain item that may be required during the process of natural usage. The following shall be carefully checked when performing product acceptance: 1.The technical data,nominal load and other information included in this manual are based on the Max crane rating.That crane rating may be hampered by instability of the truck used with crane.In this case the actual crane rating shall be rechecked. 2.Unauthorized welding operation on the Crane is strictly forbidden as it may damage the steel structure and hydraulic elements of the Crane.User shall not replace any crane parts or components with new ones other than provided with the crane by the manufacture.User shall not remove any protection devices mounted on the crane. 3.Maintenance operation shall be performed in accordance with the requirements and interval specified in Chapter 8 of this manual. 4.Some components may be the selective accessories that refer in this manual,but not standard equipment.These components including as follows: lever cylinder,additional manual boom,additional hydraulic articulated boom, hoisting unit,operation platform of different location and so on. It may be manufactured by the requirement of customers.

Chapter 1. Truck Crane Overview Section 1. Definition Technical terms used in this manual are defined as follows: Linkage Point: The point at which two or more parts are linked. Active hook: Mounted on the bottom of hydraulic boom that can dismounted on manual boom Hydraulic Boom: Telescopic hoisting arm controlled by hydraulic oil cylinder. Limit: Limiting position for a part movement. Lifting moment: Product of hoisted object weight and working distance. Operator: The person who operate the marine crane capacity. Lifting curve: A device indicating 90%-100% of Truck Crane. Working range: Horizontal distance between hook center and rotation center. Power line: Each operative fluid drive system of Marine Crane comes true. Rating lifting capacity: The Max lifing weight at a position for the crane. Standard scheme: Truck Crane that not have selective accessories Manual boom:Boom that operated by person Executive element:Refers to actuating parts such as hydraulic cylinder and motor. Control element: Refers to hydraulic valve and locks.

Section 2.Signs and Symbols The following major three reminders are commonly used in this manual to let you be aware of the specific conditions. Warning: Indicating do and donЎЇt of the crane operation, such as prohibited operations and recommended procedures. Danger: Remind the operator of possible dangers that may be hazardous to the operator or nearby persons.. Attention: Remind the operator of the conditions or instance that may be dangerous to the machine or products.

Section 4. Nameplate Nameplate shall be mounted on the turntable of Hydraulic Crane.

Chapter 2. Technical Data

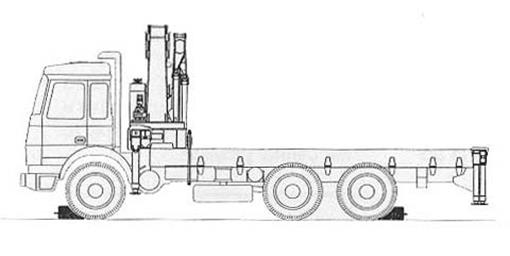

SQ5ZA2 Outline Dimension ATTENTION: Operate the Crane safely on road, suited basement of Hydraulic Crane must accord with traffic and relative juristical regulation.(i.e.beyond height and width must be allowed) Section 5. Safety Device The lock on the fixed legs The left and right on the crane there are two of the lock on it.

When the truck running,thecrane must lock.when need put out the activity legs,turn the lock round 180º,then pull out legs(or operate the level cylinder),at last,lock it,prevent the activity leg move; when draw back the activety legs,turn the lock round 180º, set the lock in the legs, prevent the activity leg move. Setting the control valve

1. the hydraulic lock on the leg cylinder 2.the turntable balance valve on the turntable cylinder 3. the first variable amplitude cylinder one-way balance valve

4. the second variable amplitude cylinder bidirectional balance valve 5. the telescopic cylinder bidirectional balance valve 6. the telescopic cylinder order valve. Basic requirement Any person operating and using this crane shall be able to satisfy the following requirement: Body condition Operators shall have qualified eyesight, hearing and coordination ability to safely fulfill the job required by crane operation. Operator shall not operate the crane after taking medicine or alcoholic drinks that may result in reduced physical ability of operation. Mental condition Operators shall be able to understand and use relevant safety and regulations and make necessary precautions to ensure safe crane operation. Operators shall have good sense of judgment to ensure safety of others and themselves, as well as to ensure a well-done job. Mood Operators shall be able to keep calm and stand normal when subjected to great stress. Operators shall also use their sense of judgment to assess their body and mantle conditions. Training This is a very important step. Operators shall read, learn and understand operation manuals and charts, warnings and signs attached thereto. Operators shall, before any crane operation,make sure that they have had a good understanding of control lever use and relevant movements. Operators shall first perform no load trial before loading the crane. If required by law, operator shall have license to operate the crane. Recommended appliances for labor protection Safety helm, work gloves, shoes and safety goggles. Responsibilities and duties Responsibilities Crane operators shall be responsible for crane power system startup, various crane operations, dismount and remount of some simple parts and maintenance on these parts. Operators shall be fully aware of the importance of safety rules and devices. They shall also be familiar with the controls and nondestructive loading/unloading techniques. Duties Operators shall be fully responsible for proper crane operation. They shall go through each step of crane maintenance and loading operations in accordance with requirements in this manual. Console The operator should stand beside the console when the crane was working.

ATTENTION Јє RememberЈstill stand the hoisting way, natural operate it.

Hydraulic oil level display There is a hydraulic oil level displayon the tank,it is clear display the oil capacity

Control system

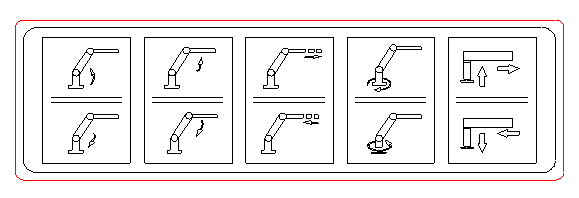

The stainless steel signboard shown below the movement of executive elements when the control lever moves upward or downward. See descriptions below for detail:

Pic A Pic B Pic C Pic D Pic E

Pic.AЈєFirst variable amplitude cylinder control. Pic.BЈєSecond variable amplitude cylinder control. Pic.CЈєTelescopic cylinder control. Pic.DЈєRotation unit control. Pic.EЈєLeg cylinder control.

Stabilization of crane ATTENTION Јє the common operation and hoisting operation should be on the same side to ensure the best visibility and operation safety.

WARNING Јє when fixed the truck,make the activity legs absolute extend out,the leg on the earth,do not let the truck hang in the air, the wheel must touch the ground. Operate the joy stick, put out the leg cylinder, generally the two of the leg cylinder put out at the same time, the leg cylinder put out touch the earth,then put out 10-20MM,adjust two sides of the crane almost in one level,the level angle less than 1Ўг,at last lock the safe valve on both leg cylinders. Note ЈєWhen the outrigger is turned, it should be operated slowly so that the outrigger will be turned to the top slowly.

If the two side of the crane is imbalance(the leg cylinder not put out at the same time), one of the leg cylinder put out touch the earth,then put out 10-20MM,lock the safe valve; other safe valve open, operate until the crane balance, then lock the safe valve.

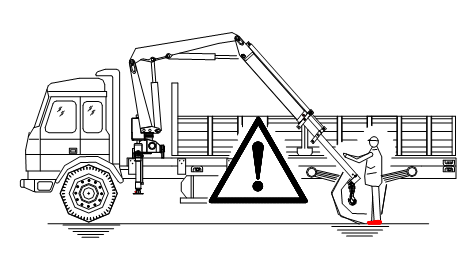

If there are gradient before the truck, operator must put block under the wheel prevent the car move back until the crane working.As the follow picture,it also need brake by hand.

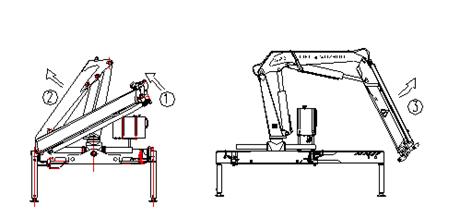

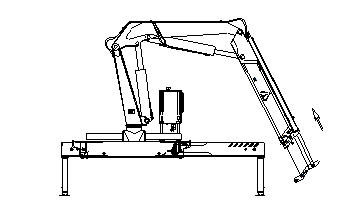

The hydraulic crane spread. WARNING Јє when the hydraulic crane delivery there are A,B two point support,as the follow picture.

(A) (B) A fixed on the fix leg, prevent the leg turntable. WARNING Јєwhen the crane delivery(leave factory),there is a lock, only open the lock, the crane can work, if not the steel of the crane will broken, like the left picture above. B the second knuckle boom cooperate with the turntable, the turntable support the second knuckle boom, prevent the boom go down.

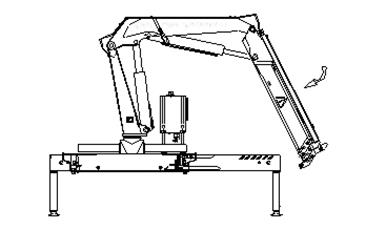

The process of extend the knuckle crane: 1.Make the second knuckle boom absolute furl, let the support point(picture B) open. 2. make the first knuckle extend. 3. extend the second knuckle.

ATTENTION Јє operator must take care of the boom and the rotation unit base.

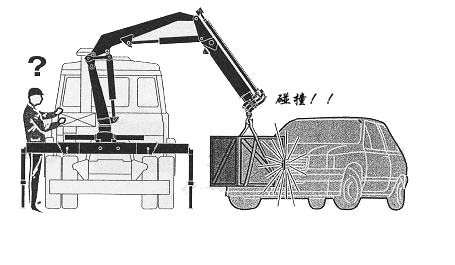

The telescopic boom operate Јє Before hoisting the goods, the operator need estimate the weight of the goods.(the same as the rated lifting moment) and count the point of fall. When put down the goods, the operate need slowly, exactly, not swing, and carefully prevent bump the truck and the crane.

In order to improve the natural life of the turntable, prevent hoisting the heavy goods turn. Before turn shorten the boom. When hoisting the goods,prevent abruptly stop and begin, this can concussion the hydraulic structure. ATTENTION Јє the telescopic boomЎЇs joy stick is the same one. The furl of the hydraulic crane.

Furl the telescopic boom: absolute furl the telescopic boom. ATTENTION ЈєDo not move when the crane working.

Adjust turntable positionЈєturn turntable until the first knuckle boom level with the fixed leg. WARNING ЈєWhen the first knuckle boom level with the fixed leg. the arrowhead on the turntable and the rotation unit base must uniform.

Furl the second knuckle boomЈєabsolute furl the knuckle boom.

Furl the first knuckle boom: make the firstly knuckle boom slowly down, the firstly head knuckle boom of preventable rotation unit should be fixed on the relative units of fastness supportive legs, refers to left chart as below

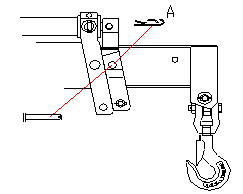

Furl the activity legsЈєopen two of the safety valves on the legs cylinder,operate the leg cylinderЎЇ joy stick, furl the left and right legs cylinder, lock all the safety valves on the legs cylinder(close).then open the lock on the activity legs, then furl it and locked it. WARNING Јє Activity leg must absolutely furl. ATTENTION Јє Make sure the activity absolutely furl, and lock it. CAUTION Јє 1. Hydraulic pump without connection with force equipment after complete work 2. After operation, check the control levers to ensure they are automatically reset. If any lever is not back to its central position, manually reset it to the central position. Use the manual boomЈЁchoose adjunctЈ© Manual boom setting Јє in order setting the manual boomЈthe boom stay as the picture show, so that is easy to operate. WARNING Јє If you want to make the hydraulic crane reach the rated capacity of the hydraulic telescopic boom, the manual telescopic boom will be removed WARNING Јє this course need two people assist.

THE PICTURE AS FOLLOWSЈє

Install the manual telescopic boom and lock it. ATTENTION Јє Ensure to make the spring replaced certainly.

Manual boom back out.

Attention Јє must rememberЈwhen open the lock, the manual boom will slide to one point, so the people need stand outside the manual boom, prevent hurt people.

Crane Service The crane shall be regularly examined and serviced to ensure that parts and components, especially safety devices, are in good condition and function properly. 1.Check the driving circuit connections. Check the entire hydraulic power driving pipes and make sure they are free of leak and distortional deformation. 2.Check the hydraulic oil level Check the oil capacity in the tank, oil level will not high up or low down the max. or the min. marks. Chapter 7. Troubleshooting

Chapter 8. Maintenance Maintenance Project Crane items listed below shall be checked and serviced regularly according to the specified intervals.

Maintenance to be performed every 50 hours: _Examine the system connections for possible oil leak; _Examine the oil cylinder for possible leak; _Examine fixing bolts of the crane and other fasteners to make sure they are properly tightened.

Maintenance to be performed every 450 hours or 6 months: _Supply lub grease to rotation bearing. _Supply lub grease to link points. _Supply lub grease to telescopic boom. _Supply lub grease to exposed portion of the oil cylinder piston rod. _Examine the slide block for possible wear, if necessary, replace the block. _Examine the wire rope for possible wear, if necessary, replace the wire rope. _Examine the bolts fixing the rotation bearing to the turntable and base of the crane. Make sure they are properly tightened. Maintenance to be performed every 900 hours or 12 months: _Examine hydraulic oil cylinder.(*) _Examine base bolts. Make sure they are properly tightened. _Examine hydraulic system and safety device. Make sure they are properly installed and in good working condition. (*) _Examine bolts fixing the crane. Make sure they are properly tightened. _Examine steel structure of the crane(*) _Examine or replace set screw and slide block. _Replace hydraulic oil. If the crane is not to be used for a long period of time(more than 18 months),the folowing maintenance shall be performed: _Remove dust and oil sludge off the crane body and keep the body clean. _Retract all cylinder pistons to the shortest position. _Lubricate moveable parts with grease. _Clean the sand and dust off the wire rope and supply ZG-S lime-base graphite grease. _Place the crane in ventilated and dry house. If outdoor storage is the case, take proper weatherproof measures to protect the crane from being wetted. _Start the crane once every month and operate the crane units for idle run to examine their working status.

Crane Maintenance Hydraulic Oil Replace Make the crane furlЈfind a big container load the hydraulic oil of the oil tank. Make the container under the oil tank, open the bolt of the bottom of the tank, expel the oil from the tank, then replace the bolt. ATTENTION ЈєPrevent the hot oil fire. Check the screw tightening Fasteners fixing the crane parts may become loosened due to vibration. therefore the following fasteners shall be regularly checked: 1-pintle clamp screw 2-shaft nut for telescopic boom 3-screw and nut for control leer 4-support bolts for change valve.

Characteristic of hydraulic oil Ўўlubricant grease Ўўgear oil Required hydraulic oil The gear oil number for summer season should be YC-N46 low pour point hydraulic oil; The gear oil number for winter season should be YC-N32 low pour point hydraulic oil in winter. According to the temperature and working condition, you should estimate whether need to mount equipment that used to be cooler or kept the fit temperature of hydraulic oil or not. The lubricant grease should be No.3 lime grease. The gear oil number for summer season should be HL-20, the gear oil number for winter season should be HL-30(SY1103-77) Warning: Before adding or replacing hydraulic oil for hydraulic power system, make sure the new oil is compatible with the old one. Do not use oil containing molybdenum and/or sulphide, or the bearing parts may be damaged. Dismount the Crane Consult manufacturer before performing any Marking Crane dismounting operation. Warning: Do not dismount the valve lock

Operation and Maintenance of Manual SQ5Z Crane

|

|||||||||||||||||||||||||||||

|

Последнее изменение этой страницы: 2020-11-11; просмотров: 119; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 3.147.53.163 (0.01 с.) |