Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Read part IV and answer the questions after it. Make sure you can explain the following terms and word combinations from part IV.Содержание книги

Поиск на нашем сайте

Part IV. Bracing. Gary R. Steficek, SOM's project engineer for the commercial tower, adds that not all of the core bracing continues to the top of the building, either. Some of the bracing stops at the 16th floor, some stops at the 40th and the rest continues to the 50th floor. Tight bay spacing was needed at the corners to help transfer the wind loads around the corners of the building. There are four 11-ft-wide bays at each end and alternating 19-ft and 11-ft bays in the center. Each end bay has a chamfered corner. Columns that had beam stubs spiced on at midspan to form Ts were used between the 11-ft-wide bays. "The [horizontal] stubs were welded on in the shop where it is a lot easier to make a moment connection," says Steficek. Mosher Steel Co., Houston, fabricated the structural steel for the theaters and commercial tower. Steficek adds that the stubs could not exceed 5-ft because they had to be transported through tunnels into New York City. That meant that for the 19-ft-wide bays, stubs could only be shop-welded onto one side of the columns and additional beams for the frame had to be fieldwelded. The steel framing that surrounds the tube in a wedding cake pattern at the building's base does not add to its stability. Steficek explains that the 18 floors of framing around the base of the tube carry only their own gravity load. The curved masonry on the exterior that is designed to mirror the arcade inside is six stories high. Steficek adds that the floor area varies from about 45,000 sq. ft at the base to about 25,000 sq. ft on the upper floors.

12. Answer the questions to part IV:

1. Who is the project engineer for the commercial tower? 2. Does all of the core bracing continue to the top of the building? 3. What was needed to transfer the wind loads around the corners of the building? 4. What columns were used between the 11-ft-wide bays? 5. What welding was used for the horizontal stubs? 6. What company fabricated the structural steel? 7. What needed field welding? 8. What is the steel framing compared to? 9. What load do the 18 floors of the framing carry? 10. How high is the curved masonry? 11. How does the floor area vary?

13. Read part V and answer the questions after it. Make sure you can explain the following terms and word combinations from part V.

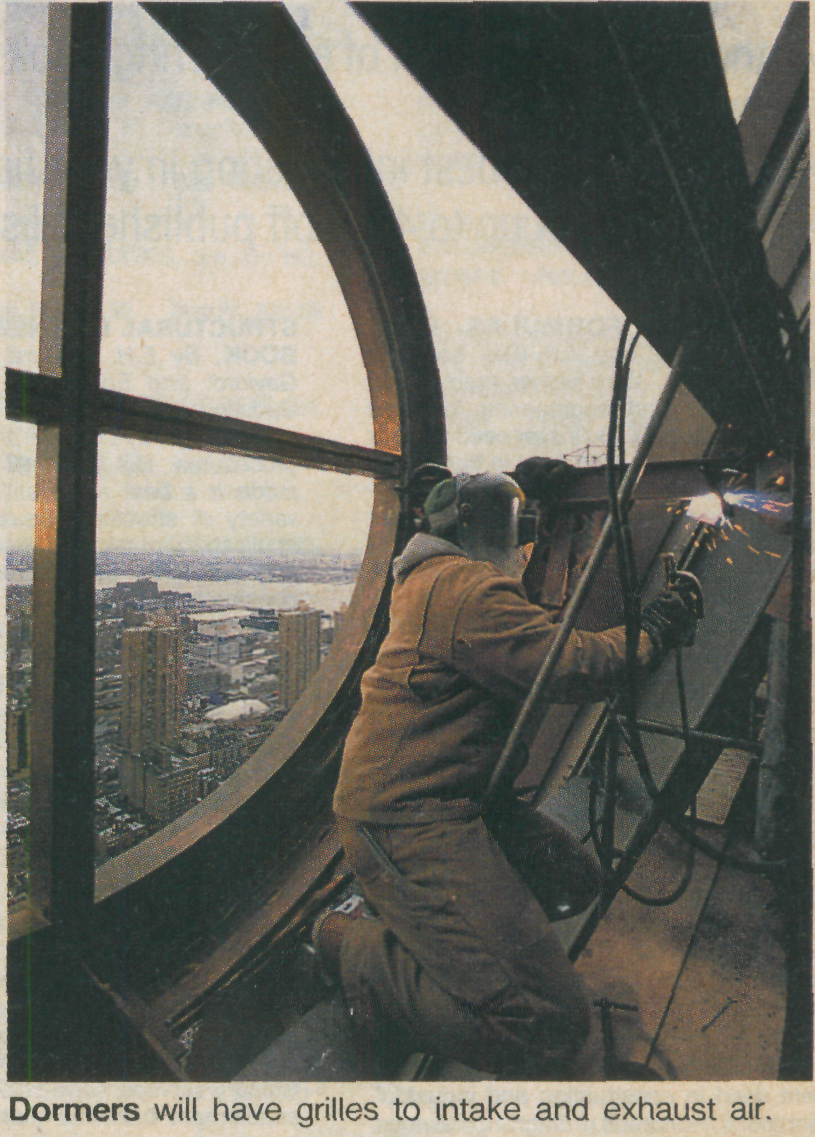

Round dormers that let air in and out through copper grilles are locate d at the top and the bottom of the 150-ft-high roof space, creating a four-story-high plenum. Bottom dormers at the 50th floor level have an air intake through cooling towers located at the 708-ft to 731-ft levels. The air is exhausted through the dormers at the top of the roof. All of the dormers are in a vertical position to reduce the chance of water intake. Mechanical-electrical design is by Cosentini Associates, New York City. The actual wind loads on the building will be higher than they are on some nearby skyscrapers because it is "away from the built-up parches of Manhattan. It does not have the sheltering effect of surrounding buildings and the biggest, strongest winds in Manhattan tend to come from the west," says Isyumov. To the west of the project, most of the surrounding buildings are five-story walk-up tenements. The roof structure, used as a penthouse for the mechanical equipment, is made of prefabricated copper panels. HRH suggested that the roof be panelizes so it could be installed like a curtain wall and scaffolding would not be needed for its erection. As results, the roof was built from the interior "with as few pieces as possible," says SOM's Rowe. The 2 x 26-ft-long copper sheets were lifted by crane and derrick, adds Peter M. Chorman, SOM's assistant project manager for the roof and arcade. They were stored on the 47th floor and on the two floors inside the roof. Subcontractor Werner Dahnz, Toronto, designed and fabricated the copper roof panels. They are made of girts with ribs "similar to curtain wall mullions that span between the girts, " says Rowe. The girts are being bolted in the field to sloping columns. The copper roof panels had to be equipped with doors to provide access to the lighting equipment that will be used to illuminate the roof. Rowe adds that SOM typically specifies that a portion of a window wall be tested for wind loads air infiltration. Here, in addition to a section of a wall, a section of the roof with dormers also was built and tested. "The first time it failed miserably. The copper loosened up in the first test," explains Rowe. The problem was corrected by increasing the bolt size and reducing the bolt spacing from 18 to about 12 in. on center. The copper panels, with copper stiffeners on 8-in. centers, are held between aluminum glazing stops that are bolted to aluminum mullions. A gasket separates the two dissimilar metals. At the top of the copper-clad roof is a pyramid space frame clad with translucent glass. The grade-level plaza, located between the residential and commercial towers, is reached directly from the arcade. Its construction was a priority because its open area was needed for the storage of construction materials on the tight midtown site. The plaza also is being used as a staging area for the fabrication of reinforced concrete sections for the residential tower and the townhouses. But before the structure supporting the plaza's landscaping, fountain and vehicular drive could be built, the project's six theaters had to be constructed. The roof of the theaters is at the bottom of the tree wells, says Michael Sardina, principal designer for the landscape architect, The SWA Group, Boston. Loading is the 10-ft-wide vehicular drive that is adjacent to the commercial tower. To support the plaza weight and get the necessary clear spans for the theaters, four 7 ½ -ft-deep girders frame parts of the underground structure. Two of the deep girders are 80ft long and two are 60ft long. The heaviest of them weigh 784 Ib. per ft. The plaza will have trees, shrubs and "a substantial amount of seating," says Sardina. Two 30-ft-high pavilions one on either side of the plaza, will provide entrances to the underground theaters as well as retail space on the plaza. To attract pedestrians and keep the public spaces active at night, the commercial tower will be washed with lights. The rooftop pyramid, lit from within, will become a beacon on the city's skyline.

14. Answer the questions to part V:

1. What envelope do most skyscrapers have? 2. Why is this project unusual? 3. What is creating a four-story plenum? 4. Where is the air intake at the 50th floor? 5. How is the air exhausted? 6. Why are all the dormers in a vertical position? 7. Why are the actual wind loads on the building higher than on nearby skyscrapers? 8. Where do the biggest winds in Manhattan tend to come from? 9. Is the roof structure used as a penthouse for residents? 10. Why wasn’t scaffolding used for the roof construction? 11. What mechanisms were used to lift copper sheets? 12. Who designed and fabricated the copper roof panels? 13. How is the access to the lighting equipment provided? 14. What was tested for wind loads and air filtration? 15. How are the copper panels held? 16. What is reached directly from the arcade? 17. What was another function of the plaza? 18. What was necessary to construct before the fountain and vehicular drive? 19. Where is the roof of the theatres? 20. What frame parts of the underground structure? 21. What will the plaza have? 22. What do the 30-ft-high pavilions provide? 23. Why will the commercial tower be washed with lights? 24. What will the roof-top pyramid become?

Comprehension check

15. Decide whether the following statements are true or false according to the text:

1. The commercial-residential complex in Manhattan is an added notch to a city skyline. 2. The structure was demolished and replaced with a surface parking. 3. Rockefeller Center and World Wide Plaza differ in functions. 4. Both plazas can be reached from two directions. 5. Excavation and foundation contractor had many obstacles in the excavation process. 6. The subway entrance was covered with graffiti. 7. The superstructure consists of an exterior tube with a braced frame at the core. 8. The arcade’s granite-clad prefabricated columns saved money on labour and time. 9. Transferring the loads over a couple of stories can be seen from the exterior. 10. The rigid frame couldn’t be interrupted because of wind stresses. 11. It is a lot easier to make a moment connection by welding in the shop. 12. The steel framing that surrounds the tube in a wedding cake pattern at the building’s base does not add to it’s stability. 13. This building has an impermeable envelope. 14. The air is exhausted through the dormers at the top of the roof. 15. The actual wind loads on the commercial tower will be lower than they are on nearby skyscrapers. 16. The roof was panelized to be installed like a curtain wall from the interior. 17. The copper roof panels had to be equipped with doors to provide access to the lighting equipment to illuminate the roof. 18. The project’s six theatres construction was a priority. 19. To support the plaza weight four heavy girders framed parts of the underground structure. 20. The commercial tower will be washed with lights to be protected from flying aircrafts.

16. What do you think:

1. Do skyscrapers have any chance to get ground in Belarus? 2. What do you know about construction industry in this country? 3. Does it follow the high-tech designs of Skidmore, Owings and Merril and other construction companies and businesses? 4. Can you imagine living in a penthouse or on the 41st floor of a skyscraper? 5. Would you like to live there or just enjoy a breathtaking view from a sky deck or working in the office on the 100th floor?

|

||||||||||||||||||

|

Последнее изменение этой страницы: 2016-08-01; просмотров: 195; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 3.143.17.175 (0.008 с.) |

Part V. Wind forces. Most skyscrapers have an impermeable envelope. This building project is unusual because both the arcade at grade level and the copper-clad roof are open to wind forces on the interior walls, says Nicholas Isyumov, research director at the University of Western Ontario's Boundary Layer Wind Tunnel Laboratory, in London, Ontario.

Part V. Wind forces. Most skyscrapers have an impermeable envelope. This building project is unusual because both the arcade at grade level and the copper-clad roof are open to wind forces on the interior walls, says Nicholas Isyumov, research director at the University of Western Ontario's Boundary Layer Wind Tunnel Laboratory, in London, Ontario.