Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Determination of cold brittleness temperature by means of serial dynamic bending testsСодержание книги

Поиск на нашем сайте

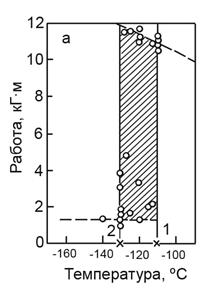

The serial dynamic bending (impact toughness) test of notched specimens is the most widespread determination method of temperature critical value (ТCR). This method is widely used at estimation of steel liability to brittleness while working at low temperatures. Low temperatures increase resistance of metals to plastic deformation and rise metals liability to brittle failure. The main aim of impact bending tests at low temperature is to define the minimal temperature at which the metal can work reliably with a small probability of brittle failure formation. The information received as a in result of conducting of series of impact bending tests at the gradual decrease of FATT is used at serial curves construction. There is a sudden lowering of impact toughness at a certain temperature (temperature interval) called the critical brittleness temperature. The critical brittleness temperature is a comparative characteristic of metal liability to brittle failure at low temperatures. The ductile-brittle transition in a short critical temperature interval appears as a result of serial tests of round unnotched specimens (fig. 3.6 a). The point 1 determines the beginning of transition, and a temperature corresponding to this point is called the upper boundary of cold-brittleness threshold. This temperature is taken as cold-brittleness threshold and is denoted as While testing of notched specimens, especially specimens made of ductile materials (for example, low-carbon steels), the ductile-brittle transition takes place gradually in a wide temperature interval (fig. 3.6 б). At determination of

Fig. 3.6. Serial curves of smooth (а) and notched (б) specimens test. The following conditions are used in some cases: а n = n а n (where 0<n<1), usually n = 0,5 or n = 0,8. Critical temperatures obtained on the basis of these criteria are marked as Appendix 1

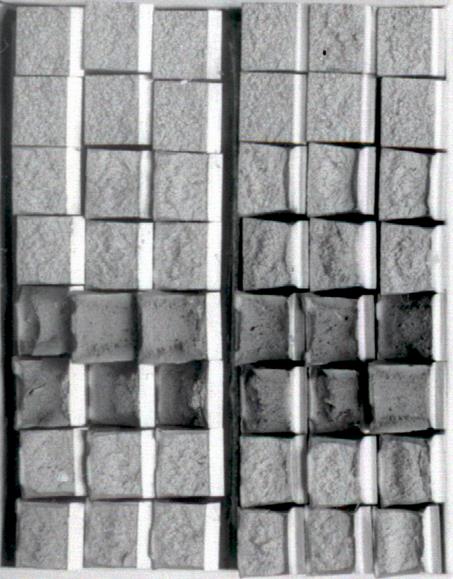

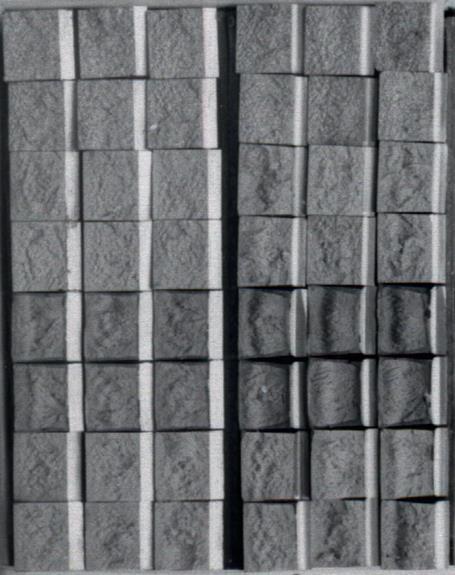

Appendix 2 KCU (type Ι)

KCV (type IV)

Appendix 3 Test temperature: +100°С

Test temperature: + 60°С

Test temperature: + 20°С

Test temperature: 0°С

Test temperature: - 20°С

Test temperature: - 40°С

Test temperature: - 60°С

Test temperature: - 80°С

Test temperature: – 100°С

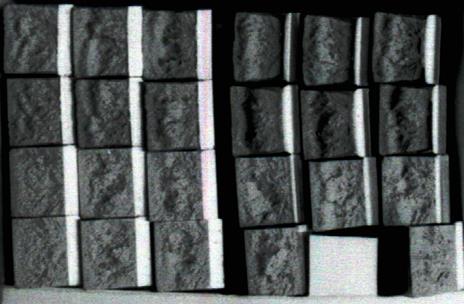

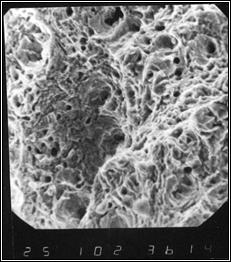

Appendix 4 Steel 80С, hot-rolled

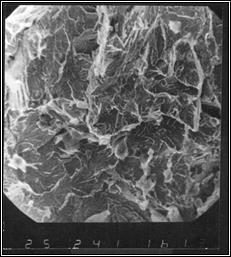

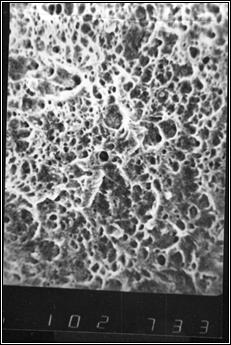

t=+20°C, х240 t=+20°C, х240

t=+20°C, х1000 t=+20°C, х1000

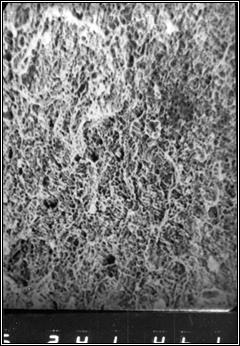

Steel 20ХГ2Т, hot-rolled

t=+20°C, х240 t=+20°C, х240

t=+20°C, х1200 t=+20°C, х1000

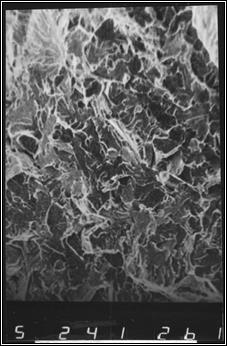

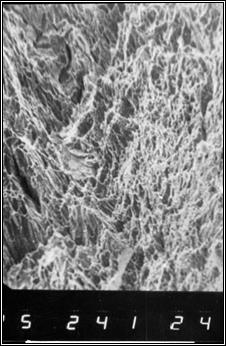

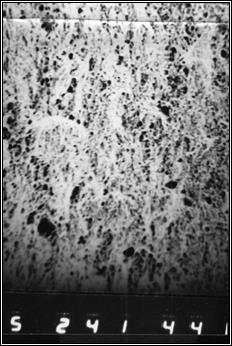

Steel 20ХГ2Т, hot-rolled

t=+20°C, х1000 t=-20°C, х240

t=-20°C, х1000 t=-60°C, х240

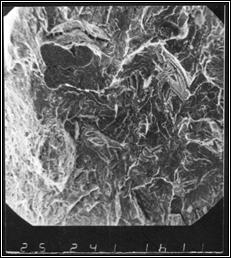

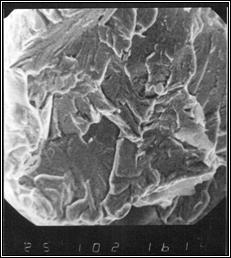

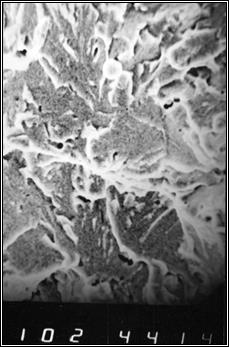

Steel 20ХГ2Т, hot-rolled

t=-60°C, х240 t=-60°C, х1000

t=-60°C, х1000 t=-60°C, х1000

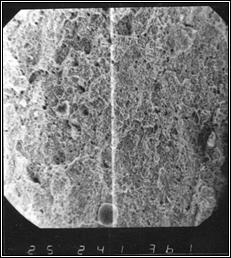

Steel 25Г2C, hot-rolled

t=+20°C, х240 t=+20°C, х240

t=+20°C, х1000 t=+20°C, х1000

Steel 25Г2C, hot-rolled

t=-20°C, х240 t=-20°C, х240

t=-20°C, х1000 t=-20°C, х1000

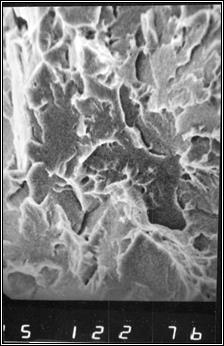

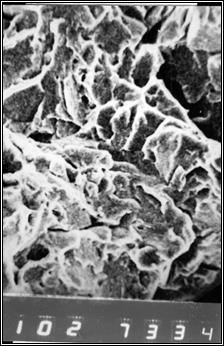

Steel 25Г2C, hot-rolled

t=-60°C, х240 t=-60°C, х1000

t=-60°C, х1000 t=-60°C, х1000

Steel of 25Г2C, TS furnace

t= +20°C, х240 t= +20°C, х240

t= +20°C, х1000 t= +20°C, х1000

Steel 25Г2C, TS mill

t= +20°C, х240 t= +20°C, х240

t= +20°C, х1000 t= +20°C, х1000 Steel 25Г2C, TS mill

t= -20°C, х240 t= -20°C, х240

t= -20°C, х1000 t= -20°C, х1000

Steel 25Г2C, TS mill

t= -60°C, х240 t= -60°C, х240

t= -60°C, х1000 t= -60°C, х1000 Appendix 5 The explanatory note to the course paper is conventionally subdivided into: - introduction; - main part; - appendix. Introduction Introduction contains the following structural elements: - title page; - task for the course paper; - abstract; - contents; - list of conventional signs, symbols, contractions, terms. Title page A title page contains information that should be represented in the following sequence: a) information about the ministry, higher educational establishment, department; b) complete name of document. The division of words in the heading of title page is forbidden; c) signatures of supervisors, tutors and the student who executed this the course paper. The signatures of responsible persons are placed in the following order: to the left there should be the white space for the personal signatures. To the right of this white space the posts, surnames, names and patronymics should be pointed in appropriate lines. Below the personal signatures, there should be pointed the dates of signing in Arabic numerals in the following sequence: year, month, date. For example, December, 26, 2002 should be designed as: 2002.12.26. or 02.12.26., verbally-digital dates design is also possible: December, 26, 2002. d) year of explanatory note drawing up. Task of the course paper The supervisor formulates and gives the task. There should be the topic of the course paper, data values, list of questions that should be studied in the task. The timetable of work stages preparation can also be shown in the task. Abstract An abstract is intended for getting acquainted with a work. It is prepared in the official (Ukrainian) language. The abstract should be brief, informative and it should contain all necessary information that allows making the decision about the expedience of all explanatory note or report reading. The abstract is placed directly after a title page. It begins from a new page. The abstract should contain: - information about the note volume, quantity of illustrations, tables, appendixes, resources quantity in accordance with the list of references; - text of the abstract; - list of keywords. The text of the abstract of the course paper should reflect the information given in the explanatory note in the following sequence: - object or research of the development; - purpose of the work; - research methods and equipment; - results and their novelty; - the main structural, technological and operational data and indices; - recommendations of the work data use; - economic efficiency; -summary. The abstract should contain one A4 page. The keywords are placed after the abstract text. The quantity of keywords should be from 5 to 15 words (word-combinations). The keywords should be written in capital letters in a line with commas. Contents The contents are placed right after the abstract. It begins from a new page. The contents include: introduction; all sections titles consequently listed, subsections titles; conclusions; list of references; appendixestitles and number of pages which the next material begins from.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Последнее изменение этой страницы: 2016-12-28; просмотров: 272; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 18.222.117.15 (0.011 с.) |

. The point 2 corresponds to the end of ductile-brittle transition. The temperature at this point is called the lower boundary of cold-brittleness threshold.

. The point 2 corresponds to the end of ductile-brittle transition. The temperature at this point is called the lower boundary of cold-brittleness threshold.

and

and  . The fixed values of impact toughness (equal to 2,5 kg×m/cm2) are also used. These fixed values are mostly used in west-european countries while testing specimens with the notch radius of 0,25 mm, its critical temperature is denoted as

. The fixed values of impact toughness (equal to 2,5 kg×m/cm2) are also used. These fixed values are mostly used in west-european countries while testing specimens with the notch radius of 0,25 mm, its critical temperature is denoted as  . The critical value of а н = 3,0 kg×m/cm2 is used in the Soviet practice, its critical temperature is denoted as

. The critical value of а н = 3,0 kg×m/cm2 is used in the Soviet practice, its critical temperature is denoted as  .

.