Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Description and estimation of a fracture typeСодержание книги Поиск на нашем сайте

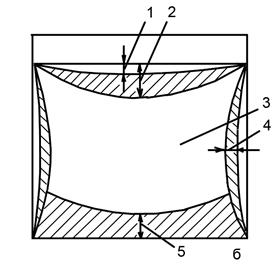

The term «fractography» appeared in the middle of 1940-s of the last century, despite the fact that the influence of heat treatment on the steel fracture type for the first time was systematically investigated by Chernov D.K. Later in 1917, Dragomirov A.M. discovered the correlation between fracture character and stress-strain diagram at static bending test. A fracture is the surface of solid failure. The fracture type gives the direct information about the failure process passing. During the metallographic analysis of section some casual cuts of metal are observed. The whole surface appeared at failure is visible in a fracture. The fracture type is qualitative characteristic unlike to quantitative characteristics of failure process. Fractures can be brittle, ductile and mixed one. As a rule, brittle fractures, appear at low energy consumptions, formation of ductile fractures is connected with high energy consumptions. A brittle crystalline fracture is characterized by shining mirror areas of considerable size called facets. The failure is accompanied by formation of comparatively smooth surfaces that reflect light under the identical angle. These areas show that the crack grew without causing considerable plastic deformation. If crack growth is accompanied by large plastic deformation, instead of even and flat areas there appear uneven wavy ones. Light from them is reflected by diffusive way. The mat surface formed by these areas is named a ductile fracture. The mixed fractures form crystalline and mat areas. The schematic structure of fracture is shown in figure 3.2.

Fig. 3.2. Scheme of fracture elements: 1 – failure center; 2 – crack formation zone; 3 – crack growth zone; 4 – contraction of fracture; 5 – rupture area.

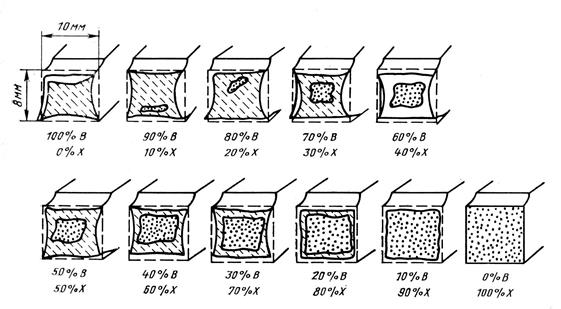

Fracture area where the crack formation took place is called the formation center. The crack formation zone adjoins the crack formation center. After them, crack growth zone follows. The rupture area adjoins the crack end in the specimen surface opposite the crack formation center. Fracture contraction is estimated by the size of maximal deformation along two profile planes parallel to directions of applied forces. It is measured in millimeters. Fracture contraction depends on the absolute specimen sizes, its width-height ratio, mechanical properties of metal and test temperature. The failure surface is characterized by a presence of: facets, pits, stages, a streamlet pattern, tongues and abruption combs. The fractures microstructure is described by means of the following terminology: - cleavage is the mechanism of brittle failure: division of metal by planes that coincide with crystallographic planes of grains (intragranular cleavage) or with the flat areas of grain boundaries (intergranular cleavage). The surface of failure consists of facets commensurable with grain size. The features of ductile deformation are absent. - quasi-cleavage is the mechanism of transcrystalline quasi-brittle failure. The division is realized by planes that don’t coincide with crystallographic planes of grains. Size of facets is less than grain size with the feebly marked features of local plastic deformation. - microvoids confluence is the mechanism of intragranular or intergranular ductile failure when the division of metal takes place by formation, growth and confluence of microvoids at the plastic yielding of metal. It is characterized by the surface of destruction that has a pit microrelief with a different degree of pits development and considerable plastic deformation of all surface. Destruction is limited by the eye resolution at visual estimation of fracture character by B (toughness). In most cases estimation of fracture character is conducted exceptionally by sight. This method is simple and widely available. So, it is recommended to use this method of estimation at preparation of the course paper. Fracture character is estimated according to the amount of the ductile areas B%. Visual determination of fibre part is conducted with the error of ±10%. As a result, deviations of obtained data from the actual values are possible. After impact bending test fractures are divided into two groups: microhomogeneous fractures and microinhomogeneous fractures with the areas of brittle and ductile failure, which is possible to expose at the visual research. Toughness determination of microhomogeneous fractures is conducted due to microfractographic analysis with application of scanning and electron microscopes. Measuring of area FCR (B estimation) of zones of brittle and ductile failure should be done at investigation of microhomogeneous fractures. It is possible to conduct measuring by means of measuring instrument, visual comparison of investigated fracture type with a scale (fig. 3.3) or by typical fractographs with a different part of ductile constituent (fig. 3.4) and planimetry of enlarged image.

Fig. 3.3. Scale of fractures with a different part of ductile constituent (B is ductile constituent; Х is brittle constituent).

Fig. 3.4. Typical fractographs of fractures with a different part of ductile constituent in percents.

The curve of temperature dependence should be built in В-Т coordinates according to the mean value of ductile constituent part at each test temperature. There is a temperature when the set amount of ductile constituent is observed in a fracture. Such temperature should be found on a given graph (fig. 3.5).

Fig. 3.5. Temperature dependence of ductile constituent part in a fracture.

It is necessary to remember that the fracture character is the qualitative characteristic and it is impossible to define the amount of energy that is absorbed at destruction development. Determination of fiberness percentage (В%) is rather subjective and visual determination of fracture character is not always possible in practice.

|

||||

|

Последнее изменение этой страницы: 2016-12-28; просмотров: 209; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 3.15.1.180 (0.007 с.) |