Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

read the texts describing different types of furnacesСодержание книги

Поиск на нашем сайте

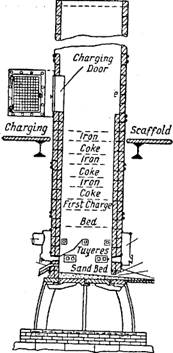

Unit 8. Types of furnaces. Task: - read the texts describing different types of furnaces - make a plan to each text - make up 5 questions to each of the texts - retell any text you like THE CUPOLA FURNACE The cupolais the oldest type of furnace and the most economical. It may be obtained in different sizes and can be operated for as long a time as may be required to produce a given amount of melted metal. It is difficult to produce metal of precisely uniform quality in the cupola as compared to furnaces in which uniformity of the molten material can be controlled by frequent and periodic tests and adjustment. Cupola capacities vary from 1 to 15 tons of metal per heat (the amount of metal melted at one time). The cupola is a cylindrical shell constructed from boiler plate and lined with firebrick. The main furnace structure is usually supported on cast-iron legs, and the opening at the bottom of the furnace may be closed by cast-iron doors, which swing up into position and are held closed by an iron upright at the center. Refractory sand protects these doors during the melting of the charge, which is placed over the layer of sand. At the end of the melting operation, the doors swing out of the way and materials remaining from the charge drop down through the opening. On one side of the cupola, level with the bottom, is the breast opening for lighting the fire. This opening is also used as the tap hole. Opposite the tap hole, and somewhat higher, is the slag hole. The charging door is located approximately halfway up the vertical shell. The top of the cupola is open except for a metal shield. A single row of openings or tuyeres is arranged around the circumference of the shell's interior at its base as a means of introducing air to the coke bed. A wind box, externally circling the cupola at the level of the tuyeres, supplies the air. Cupola Zones.— A foundry cupola is generally divided into a number of zones: the cruciblezone, tuyerezone, combustionzone, meltingzone, preheatingzone, and the stackzone. The crucible zone is located at the bottom of the cupola; it is situated in the space between the sand bottom of the furnace and the bottom of the tuyere openings. Molten iron and slag accumulate in this space between the burning pieces of coke. The tuyere openings are above the cruicible and take up a space from 3 to 6 inches in depth depending upon the size of furnace. The combustion zone is that section of the cupola which extends from the bottom of the tuyeres to the top of the coke bed. The melting and preheating zones extend from the top of the combustion zone to the charging door. The location of the charging door depends upon the size of the cupola. High charging doors, however, are recommended for large cupolas which are run all day, since greater fuel efficiency can be gained from the use of such charging doors. The purpose of the stack, which is another zone of the cupola, is to carry off the waste gases. It is located above the charging door. A roof hood is usually fastened to the stack to prevent leaks around the cupola.

NOTES AND COMMENTARY cupola furnace -вагранка at one time -одновременно lined with firebrick –облицованный огнеупорным кирпичом is usually supported on cast-iron legs –обычно поддерживается чугунными опорами swing up into position -закрываются held closed –держатся закрытыми iron upright –чугунной подпоркой refractory sand –огнеупорный песок melting of the charge –плавка загрузки swing out of the way -открываются drop down –падать вниз on one side –с одной стороны level with the bottom –на уровне с днищем breast opening –окно, летка tap hole –выпускное отверстие slag hole –шлаковая летка charging door –загрузочное отверстие except for a metal shield –кроме металлического щита coke bed –коксовая колоша wind box –воздушная коробка the crucible zone –тигельная зона tuyere zone –фурменная зона combustion zone –зона горения preheating –(предварительный) нагрев stack zone –шахта (печи), зона отвода газовtake up a space –занимать пространство the top of the coke bеd –верхний слой коксовой колоши to carry off the waste gases –выводить лишние газы roof hood -покрышка, зонт

|

||||

|

Последнее изменение этой страницы: 2024-06-17; просмотров: 7; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 18.117.71.239 (0.007 с.) |