Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Methodological approaches to tender procedures ⇐ ПредыдущаяСтр 4 из 4

In corporate procurement management in companies Vanchukhina Lubov Ilyinichna [1] , Leybert Tatyana Borisovna [2] , Khalikova Elvira Anvarovna [3] ,Khanafieva Ilnara Ravilyevna [4] , Giedrius Ciras [5] Abstract Tendering procedures are a fundamental stage in the corporate procurement management system, which determine not only the quality of logistics systems, but also the efficiency of the entire supply chain value to the company. The article describes the prerequisites for the development of corporate procurement management system in the company, including the improvement of tendering procedures. In addition, the analysis of foreign and Russian practice of tender procedures, formulate the main shortcomings and areas for improvement of the procurement system in the creation of the procurement strategy and sup-ply chain assessment values. The authors offer a method of pre-qualification selection of suppliers to improve the efficiency of procurement in the company based on the SRM-system usage analysis and category management principles. The proposed method consists of three stages of selection of suppliers based on their assessment of the re-liability and priority technical and economic evaluation of the tender offer. Technical evaluation of the tender offer should be based on the following criteria: health and safety, industrial safety, environmental safety. Final evaluation of the tender offer consists of two components: the technical and price evaluation, which corresponds to the concept of a three-factor the company's development in the long term, based on environmental safety, occupational safety and social partnership. Keywords corporate procurement, tendering procedures, SRM-system, pre-qualified suppliers, the evaluation of the tender offer the supplier a technical assessment, pricing assessment Scoping reliable suppliers, the procurement strategy JEL Classification Codes: G20, G38, G39 Introduction In the context of the rapidly evolving pro-curement practices in the public and corporate sector of the economy of foreign countries and Russia remains one of the most urgent issue of open, transparent, and "healthy" competitive environment during the tendering and selection of suppliers. Efficiency of procurement policy is based on the well-organized vendor-selection process, taking into account the administrative procedures for procurement activities and best practices of its implementation in companies. In addition, when choosing a supplier it is necessary to consider two opposing factors that regulate the optimum choice of supplier during the tendering procedure - is the preservation and diversification. Preservation factor highlights the need for procurement with existing suppliers with experience in this market, a high level of staff qualification and obtained the status of a reliable supplier. Diversification factor is characterized by the application of the principles of alternative supplier selection in order to select the best conditions of delivery, better quality and lower cost Diversifying the suppliers, the customer creates a competitive environment, which has the right to choose and determine the best conditions of delivery, ensuring the effectiveness of procurement in the latter company (Forge, 2013). Given the above, in the formation of policy and tender procedures for selecting suppliers for the delivery of material assets (services, works) in corporate procurement management system it is necessary to use modern methodical approaches. These approaches are based on the ranking and the diversification of suppliers, not only on the price criterion, but also take into account many important criteria that characterize the qualitative aspects of procurement in the company. The authors presented the research analyzed the best Russian and foreign practice of procurement management in corporations regarding tender procedures and offer a multi-stage method of ranking and the subsequent selection of suppliers on the basis of price and non-price criteria.

Materials and Methods Under the conditions of administering competitive procurements, Russian companies want to receive financial savings, but also provide deliveries with better material and technical resources, services and work. In this regard, the company-customer is subject to special requirements for participants in corporate procurement, and apply various methodological approaches to competitive selection of suppliers based on a combination of price and non-price criteria. Establishment of criteria for the selection of suppliers or prequalification is carried out with the aim of: 1) reduce the risk of non-performance of the contract by the supplier; 2) reduction of time for carrying out procurement procedures; 3) ensuring increased publicity of procurement; 4) ensuring the development of fair competition; 5) the organization of continuous provision of the production process with material and technical resources, work and services; 6) increase the efficiency of the procurement activities of the company. The main criterion for selecting a supplier is price. Non-price criteria also act as additional criteria: qualification of the participant, work experience, business reputation, financial condition and creditworthiness, and others. The results of the analysis of the used Russian methods of prequalification of suppliers in the tender management system in theory are presented in table 1. Table 1 - Analysis of the used methods of prequalification of suppliers in theory

In the scientific literature and tendering practices in large companies, a wide range of techniques is used, which are based on a phased selection of suppliers, on a preliminary analysis of the priority of suppliers for non-price factors, on a preliminary multi-criteria selection based on hierarchy analysis.

The analysis of the methods of prequalification of suppliers in theory allows us to conclude that the proposed methodological approaches to grouping purchases by level of complexity and grouping suppliers by their degree of importance and reliability should be used in modern procurement management practices in Russian companies. Given the established practice of conducting two-stage selection of suppliers in Russian companies, suppliers should be differentiated to ensure the reliability of the organization of competitive suppliers and the formation of a procurement strategy. Results.

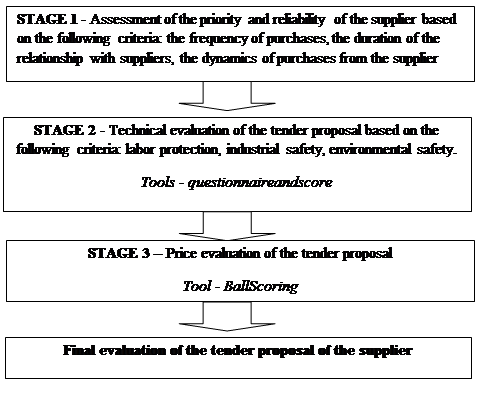

It is proposed to conduct a two-stage tender based on price and non-price criteria. The proposed algorithm for the preliminary selection of the supplier in the tender management system in companies is presented in Figure 1. Figure 1 - The proposed algorithm for the preliminary selection of the supplier in the tender management system in companies In accordance with the current rules for the administration of procurement procedures, a two-stage tender should be held with respect to the acquisition of capital facilities, research and development, supply of sophisticated equipment, and the provision of services (E. Suchkova, 2016). At the first stage of the tender procedures, the priority and reliability of the supplier should be assessed based on the following criteria: reliability and reputation of the supplier, duration of partnerships, work experience and specialization, level of security. At the second stage, a technical evaluation of the tender proposal is carried out, and at the third stage - a price evaluation of the tender offer, where the best supplier who offers the lowest price is selected. Based on the technical and price estimates, the final evaluation of the tender proposal is displayed, that is, the place occupied by the tender proposal in the tender is determined by summing the technical and price estimates taking into account the significance factors of each of them. Depending on the complexity of the work (services) and their threshold price, the ratio of the importance of technical and price estimates may vary. These ratios (coefficients) are presented in table 2. Table 2 – Proposed Ratios

The technical evaluation of supplier documentation is carried out on a 10-point scale, which takes into account factors such as occupational safety, industrial safety, environmental friendliness (environmental protection) and other parameters. The technical evaluation of the tender proposal is based on an assessment of the factors determining the reliability of the potential supplier, his experience and ability to manufacture (deliver) the goods, as well as the conformity of the goods with the specified tender documentation with technical parameters. The total assessment of the technical part of the tender offer

where

The results of the technical evaluation of each tender proposal shall be recorded and signed by experts. Protocols are transmitted by experts to a senior expert who determines the arithmetic mean of each tender proposal by formula:

where N - the number of experts who evaluate the technical part of the tender proposal. The final evaluation of the technical part (Ct) of each registered applicant is determined by the formula:

where The third stage is the price evaluation of the tender proposal (Cpi), which is carried out by the senior expert on the formula:

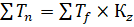

whereP min – minimum bid price; Pi - price of the tender proposal of a particular applicant. A price estimate characterizes the competitiveness of the tender offer and consists in determining the ratio of the minimum price offered in the tender proposals to the price of the tender proposal under consideration. In this case, the price is given taking into account all the costs of the supplier for the manufacture, delivery and other costs in accordance with the conditions specified in the tender documentation. If necessary, calculations are carried out to bring prices to a comparable form. The final evaluation of the proposal is determined as the total of the two components of the technical evaluation (Сt) and price evaluation (Сp), multiplied by the corresponding coefficients of significance (Кt and Кp respectively) and is determined by: С = Сt * Кt + Сp * Кp. (5) The final evaluation of the tender proposal determines the place of the tender proposal in the tender. Discussion Foreign practice shows that corporate procurement management is an area that is related to the supply chain of material and technical resources to meet the needs of the company’s main production processes. The corporate procurement management system includes the following integral procedures and steps: development of a procurement strategy; information support for the procurement management system; organization of supplier relationships; and performance monitoring and risk assessment of procurement activities (M. Forge et al., 2013).

A large number of scientific publications focus on supply chain management, both in the context of the contract system and for the purpose of meeting the overall need for material resources (works and services) in corporations and large companies. Corporate procurement is not just a centralized supply of the necessary resources to support the company’s core business processes, but a whole system that assesses the economic feasibility of using the material resources purchased in terms of product quality, technical and environmental safety, and estimating the cost of delivering and maintaining it throughout the life cycle. There are many models and approaches. For example, public and corporate procurement management in the United States uses the technology of managing a single cycle of forecasting, placement, and use of contracts. The efficiency of procurement is significantly affected by strict regulation of procurement procedures, competitive bidding procedures using a single methodology and library of model contracts and a data bank for purchased goods. Centralized organization of procurement for public and corporate needs is intended to ensure information openness, transparency of procurement and healthy competition (P. Paulov et al., 2018). In particular, in the scientific paper "Circular supply chain management: A definition and structured literature review," a group of authors presented a literary review of the application of supply chain management technology (CSCM), which is based on the purchase and supply of goods taking into account the assessment of their circular consumption and responsibility for the quality of the goods. This technology is also a system for managing complex supply chains of raw materials and components to the company, including the entire cycle of movement - from the purchase of raw materials and materials to the delivery of finished products on time to the end-user (M. Farooque et al., 2019). Savchenko V.V. notes that SRM-sistem (Supplier Relationship Management System) (V. Savchenko, 2016) is used for optimal interaction with suppliers in foreign corporations. It is a set of consistent procedures used in the procurement system and aimed at the interaction of the company with potential suppliers. While in most Russian companies the traditional choice of supplier is based on the concept of obtaining procurement savings, in foreign practice procurement is the concept of a logistics system for basic business processes, based on the establishment of long-term partnerships and strong ties with suppliers. SRM-sistem includes the following procedures: - Segmentation of procurement by resources, suppliers and other parameters; Ranking suppliers and setting key performance indicators; - Planning of procurement depending on the need for logistical resources, taking into account changes in the external and internal conditions of the company. Within SRM-sistem and Supplier Partnership, it is fundamental to develop a procurement strategy and total cost of ownership (J-S. Lin et al., 2011). Based on the results of procurement segmentation and supplier ranking, the total cost of ownership of the material and technical resource is determined, from the stage of procurement to the stage of its liquidation and write-off from production. The mandatory steps in the tender procedure are the pre-qualification of suppliers and the valuation of supply chain costs. The group of authors (O.Karabak et al., 2019) in their scientific article gave an analysis of the main factors that have a significant impact on the reduction of the purchase price of the purchased goods during electronic auctions. The number of suppliers involved and the product category have a significant impact on the lower purchase price as the main factors. Therefore, in order to effectively manage corporate procurement, it is necessary to classify the purchased products into categories and to establish a procurement and supplier selection procedure for each of them.

Conclusion Thus, the proposed supplier selection methodology, based on the multi-step evaluation of price and non-price criteria, taking into account the priority and reliability of suppliers, allows, unlike existing approaches, to follow the concept of three-factor development of the company in a strategic perspective based on environmental safety, industrial safety and social partnership. In this case, the supplier priority controlling should be carried out at the supplier prequalification stage. References Forge, M.M. (2013). Procurement Guide: studies. manual. Higher School of Economics, 695 p. PaulovP., Sotnikova V. (2018) «Experience of management of purchases in the USA» // Bulletin of Science and Practice. -Т. 4.- №11. – P. 401-404. - [Electronic resource] –// URL: http://www.bulletennauki.com. FarooqueM., ZhangA., ThürerM., T. Qu, D. (2019) «Huisingh Circular supply chain management: A definition and structured literature review» // Journal of Cleaner Production. - №228. – P. 882-900. Savchenko, V.V. (2016). Analysis of foreign experience in public and corporate procurement management.MID (Modernization.Innovations.Development). 166. - 169. LinJ-S.,Ou Jerry J.R. (2011) «A study on supply chain value-odded logistics based» // International Journal of Electronic Business Management. – Vol. 9. - №1. – Р. 58-69. Karabağ O., Tan B. (2019) «An empirical analysis of the main drivers affecting the buyer surplus in E-auctions» // International journal of production research. - №57(11). – P. 3435-3465. Monitoring the application of the Federal Law (July 18, 2011) № 223-FL “On the procurement of goods, works, ser-vices by certain types of legal entities”. [Electronic re-source]. - URL: http://base.garant.ru/ (appeal date 04/22/2018). Federal Law "On the procurement of goods, works, services by certain types of legal entities" (July 18, 2011) № 223-FL // [Electronic resource]. - URL: http://base.garant.ru/ (appeal date 04/22/2018). Kutuzov, D.V., Bykova E.P. (2008). Application of the hierar-chy analysis method to the choice of a supplier in the implementation of the “procurement” process of the quality management system. Caspian Journal: Man-agement and High Technologies. 57-62. Suchkova, E.A. (2016). Comprehensive decision-making methods for choosing a supplier on the example of the purchase of dental equipment. Economics and Manage-ment: analysis of trends and development prospects. 249- 254. Kozlova, E.V., Volynsky, V.Yu. (2015). Improving the pro-cess of preliminary assessment of suppliers of material resources at a machine-building enterprise. Economic analysis: the oryand practice. 47 - 60. ПРИЛОЖЕНИЕ 4 Образец рецензии

Рецензия на научную статью «Methodological approaches to tender procedures

|

|||||||||||||||||||||||||||||||||||||||

|

Последнее изменение этой страницы: 2020-03-26; просмотров: 256; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 3.15.22.163 (0.038 с.) |

is determined by the following formula:

is determined by the following formula: , (1)

, (1) - evaluation of the technical factor of the tender proposal on a 10-point scale;

- evaluation of the technical factor of the tender proposal on a 10-point scale; - the weighting of technical factors.

- the weighting of technical factors. , (2)

, (2) (3)

(3) - maximum estimate from arithmetic mean estimates of technical part.

- maximum estimate from arithmetic mean estimates of technical part. , (4)

, (4)