Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь FAQ Написать работу КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Describe transformation of microwave energy into heat oneСодержание книги

Поиск на нашем сайте The conversion of microwave energy to heat and the consequent rate of heating depends upon the properties of the energy source and the properties of the dielectric. In addition the heat capacity of the food and other physical properties are important because once microwave energy has been absorbed heat is then transferred throughout the food mass by conduction or convection. The microwave properties are the field strength E, usually quoted in V/cm, and the microwave frequency υ in Hz. The food to be heated must be characterized by the dielectric constant and the dielectric loss tangent. The relative dielectric constant (or relative permittivity) ε' is a measure of the ability of a material to store electrical energy and is defined as the ratio of capacitance (or permittivity) of the dielectric material to the capacitance (or permittivity) of a vacuum. Air approximates to a perfect vacuum and therefore the dielectric constant for air is approximately unity. It is a dimensionless quantity. The loss tangent δ is a measure of how a material dissipates electrical energy as heat. These properties are often combined to give the relative dielectric loss ε'' (which also is dimensionless) and therefore ε''= ε'tg δ The power dissipation or rate of energy conversion per unit volume

The absorption of microwave energy is thus increased by the frequency of the waveform and especially by the field strength. The greater the value of ε'' the greater will be the dissipation of thermal energy and the more suitable is the food for microwave heating. Table 4.1 gives the values of relative dielectric constant and relative dielectric loss factor for a range of foods. Table 6.1 – Dielectric properties of some foods

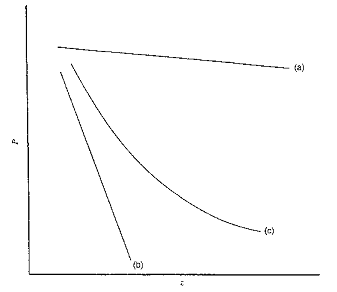

However, the suitability of a food for microwave heating is crucially dependent upon the penetration characteristics (i.e. ability to penetrate). Figure 6.3 shows microwave power as a function of penetration depth. Curve (a) is obtained with poor attenuation, i.e. poor absorption and volumetric heating and is typical of ice and frozen foods. The other extreme condition is curve (b) where the incident energy is absorbed at or near the surface giving poor penetration and only surface heating and is similar to the effect of conventional radiative heating. The ideal curve would be a linear relationship between power and depth. However, the most usual characteristic is an exponential curve of the form of curve (c). The loss of power with depth can be expressed in terms of the penetration depth which is defined as the distance from the surface at which the power has decreased to a fraction of e-1 of the incident power (about 36.8%).

Figure 6.3 – Absorption of microwave energy as a function of penetration depth. The power P at the penetration depth z may be expressed in view:

where P o is the incident power; α' -is the attenuation factor defined by the formula: where λ is the wavelength. A very large value of α' suggests poor absorption and a low value indicates that heating will take place only at the surface. Energy at a frequency of 915 MHz will penetrate more deeply than energy at 2450 MHz and will be more appropriate for thicker food pieces. Describe kinds of microwave processing of foods? Microwave baking The quality problems observed in microwave baked products are firm and tough texture, rapid staling, lack of colour and crust formation and a dry product. Firm and tough texture are related to microwave induced gluten changes, high amylose leached out during baking and insufficient starch gelatinization. Long exposure time in the conventional oven ensures the completion of Maillard reactions responsible for browning. In microwave ovens, heating is short and heat is absorbed by the food and the air around the product is cold. Therefore, evaporated water molecules from the food directly come across this cold air around the product and condense. This prevents browning and crisping reactions. There is internal pressure and concentration gradients are formed at microwave heating which increase the flow of liquid through the food to the outside. Therefore, foods heated in a microwave oven lose more moisture than conventional heating. The studies in recent years about microwave baking involve issue of improving the quality of microwave baked products. It was found that gluten content is the significant factor in affecting the firmness of microwave baked breads. Breads prepared from low gluten flour were softer and had higher volume compared to the ones formulated with high gluten flour. Increasing fat, emulsifier and dextrose contents promotes reducing the weight loss of microwave baked cakes. Usage of emulsifiers and gums retarded the staling of microwave baked cakes. Emulsifiers and gums had also synergistic effects. Fat content significantly reduced the variation of firmness and weight loss of microwave baked cakes during storage. Combination of microwaves with halogen lamp heating is a recent development in microwave baking. It combines advantages of each method: - for heating by halogen lamp is browning and crisping; - for microwave heating is time saving. Microwave drying High temperatures or long drying times in conventional air drying may cause serious damage to the colour, flavour, nutrients and rehydration capacity of the dried product. Microwave drying may be an alternative to preserve quality of dried product. It is suitable for products having a high moisture content like carrot, mushroom and cabbage because of the high dielectric properties of water that can quickly absorb the microwave energy. The physical mechanisms involved in microwave drying are different from the mechanisms of conventional drying. The internal heat generated during microwave heating provides a vapour pressure within the product and pumps the moisture to the surface. Case hardening does not occur in microwave drying because of this moisture pumping effect. Thus, an increased drying rate without increased surface temperature and improved product quality are obtained. However, the progress of microwave drying at the industrial level has been relatively slow due to its high initial capital investment. Non-uniform heating is another problem that hinders the commercial application of microwave drying. Usually microwave heating is applied in the end of drying i.e. in the period of falling rate. Generally, microwave drying of foods or food ingredients with high moisture content (over 20 % moisture) is not economical. Although water has a high dielectric constant and absorbs microwaves easily, it also has a very high specific heat capacity. In general, microwave energy has been combined with hot air to shorten the drying times especially in the falling rate periods. This method is applied for drying orange slices, garlic, soybeans, berries, apple, asparagus, carrot and potato. It is known that the unsaturated fatty acid content of foods reduces significantly during drying due to high air temperatures. Therefore, microwave drying of soybeans, which is an excellent source of unsaturated fatty acids, becomes significant. A combined ‘microwave-hot air’ technique applied to garlic cloves resulted in saving of about 80–90 % of conventional drying time. Garlic cloves dried by a combined ‘microwave-hot air’ process were lighter in colour compared to hot air dried ones because of a lower drying temperature and shorter time. The retention of volatile components responsible for flavour strength was also higher in ‘microwave-hot air’ drying. Microwave drying is a potential production method for some spices like red pepper. Red pepper is one of the best substrates for aflatoxin production. It is advantageous to use osmotic pre-treatment prior to microwave drying in terms of quality improvement. Osmosis dehydration can be conducted in sugar or salt solution. The problem of non-uniform heating in microwave drying has been overcome for particulate materials by combining microwave and spouted bed drying. Another recent advance in microwave drying to improve food quality and temperature distribution is the use of intermittent microwave drying. In traditional convective drying processes a continuous constant air temperature, humidity and airflow is used for moisture removal. In intermittent drying, drying is achieved with time varying of temperature and flow rate.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Последнее изменение этой страницы: 2016-04-07; просмотров: 668; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 216.73.216.156 (0.007 с.) |

(measured in W/cm3) is given by:

(measured in W/cm3) is given by:

,

,