Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Матер. Sci. и англ. A254 (1998), стр. 282-295.

[2] А. Молинари и др. «Первичные карбиды в быстрорежущей стали HSS для горячих валков и их влияние на окислительное поведение». Труды 6 th Инструментальная конференция, Швеция (2002), стр 437-452. [3] Xiaodan Zhang и др. «Превращение карбидов при аустенизации и его влияние на износостойкость валков из быстрорежущей стали», Met. и матер. Trans.A, Vol. 38, (март 2007 г.), стр. 499-505. [4] Хангуанг Фу и др. «Исследования по термообработке валка из быстрорежущей стали». Журнал Матр. И англ. Перф., Т. 17 (2008), стр. 535-542. [5] Л.А. Добжанский и др. «Влияние термической обработки на структуру новой инструментальной стали 47CrMoWVTiCeZr16-268 для горячей обработки». Журнал Mater. Процессы. Техно., Тт. 157-158 (2004), стр. 472-484. [6] Фрэнк Мартини, «Черновой рабочий валок для станов горячей прокатки». Proceedings of Rolls 2000 + Conference, Бирмингем, март 1999: 269-280.

[7] Жаклин Леконт-Бекерс, и др., «Металлургический

Оценка двух марок валков из быстрорежущей стали для стана горячей прокатки», Труды AISTTech 2007.

[8] Жаклин Леконт-Бекерс и Жером Чуфанг Чуинджанг,

«Структурные исследования влияния затвердевания и термической обработки на высоколегированные марки чугуна с добавками Nb-Ti-V», Defect and DiffusionForums, Vols. 289-292 (1009), стр 77-86.

[9] Мадлен Дюран-Шарр, «La microstructure des aciers et des fontes - Genèse et interprétation», SIRPE Editions, Paris (2003), стр. 122–124. [10] Джером Т. Чуинджанг и Жаклин Леконт-Бекерс «Поведение при плавлении и кристаллизации многокомпонентных сплавов Fe-C-Cr-X: микроструктурные аспекты», Труды 13-го Европейского конгресса по микроскопии, Антверпен, Бельгия (2004), стр. 651- 652.

40 Приложение № 3 New Trends in Hot Strip Mill Roughing Mills: Characterization of High Chromium Steel and Semi-HSS Grades

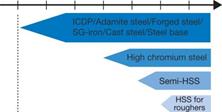

seen in Figure 1. The ever-increasing require- ments for roughing mills, in terms

of cost/performance ratio, includ- ing higher throughput, improved product quality and higher safety standards, prompted European rollmakers in the early 1990s to develop a new roll grade for rough- ing stands, which is known as semi- high-speed steel (semi-HSS). This new grade was considered to be a real revolution in terms of roll performance in nearly all aspects of the required behavior. Semi-HSS acquired a strong posi- tion, especially in Western Abstract Two alloys grades for work rolls used in the roughing stand of Hot Strip Mill — high chromium steel (HCS) and semi-high-speed steel (semi-HSS), In this paper, the new semi-high-speed steel grade is studied.

Figure 1 European HSMs. However, some applications like stain-

Dominant roughing mill work roll grades in the world.

Figure 2 1950 1960 1970 1980 1990 2000 2010

History of HSM roughing mill work roll grades from 1950 to 2010. less and special steel rolling have shown interest of fur- ther development to overcome some insufficiencies of semi- HSS. A special high-speed steel (HSS) grade for roughing mill application was developed to meet this new challenge in the late 1990s (see the history of work roll development in Figure 2). Work Rolls Grades for Roughing Stands Chemical COlTlDOSition — The typical chemical composi- tions of the main roughing roll grades used today in hot strip rolling are listed in Table 1. This table indicates the main elements such as carbon, chro- mium, tungsten equivalent, MC-carbide-forming elements as well as the carbide content and hardness range of the dif- ferent roughing roll grades. Semi-HSS 1 and semi- HSS 2 are semi-HSS grades Authors

Beckers head of metallic materials science unit, aerospace and mechanics department, University of Liege, Liége, Belgium jacqueline.Iecomte@uIg.ac.be

Mario Sinnaeve director, R&D and quality, Marichal Ketin Belgium,

T. Jerome Tchuindjang researcher, MMS unit, University of Liege, Liége, Belgium j.tchuindjang@uIg.ac.be

This article is available online at AIST.org for 30 days following publication.

with different carbon contents. Both grades contain MC-carbide-forming elements, whereas the semi-HSS 3 shows the highest MC-carbide forming elements con- tent (V, Ti, Nb, Ta, etc.). The chrome steel grade microstructure is mainly determined by a matrix of tempered martensite with eutectic carbides of the M C3 and M6C type. The highly increased hardness of matrix and of the different car- bide types other than cementite have determined a much higher wear resistance and fire crack resistance compared to former standard grades. In the mid-1980s, this roll type became a standard roughing mill work roll grade. The semi-HSS grade is characterized by a matrix of tempered martensite with a strong effect of temper hardening, where special carbides of the MgC3, M6C and MC type are embedded. This structure already offers the typical characteristics of HSS grades like high-temperature strength and hot hardness. The latest-developed HSS grade for roughing stands has increased amounts of MC and M6C carbides replacing, to a greater extent, the M2C3 type carbides. Both semi- HSS and HSS for roughers do not present a continuous carbide network. These last two roll grades are submit- ted to a long, sophisticated heat treatment, which is responsible for the homogeneous basic structure and contributes to their high performance level.

Figure 3

The type, hardness and amount of these carbides have a strong influence on wear resistance, surface deterioration and oxidation behavior of the different roll types.*** The present work will be focused on Cr steel and the three semi-HSS work rolls. Microstructures — Many different roll grades have been used in roughing stands of HSMs since the begin- ning of hot strip rolling.6 Only some recent roll grades will be discussed here in further detail. The microstruc- tures of these grades are shown in Figure 3.

Metallurgical Gharacterization Thermodynamical Simulations — Thermodynamical simulations were obtained from Thermo-Calc" soft- ware (TC). Examples of equilibrium diagrams of Cr steel and semi-HSS 3 are shown in Figures 4a—d. TC simulations assume constant equilibrium conditions, which means a very low cooling rate where ideal diffu- sion is allowed for all the alloying elements either in the liquid or in the solid state. These figures show the phase volume fraction of stable phases in the studied alloys between 500 and l,500°C with a l0°C step. From TC simulations, it appears that the first solid is almost the face-centered cubic austen- ite, except for the semi-HSS 3 grade, where the first solid to precipitate is the bold-centered cubic delta fer- rite. From this statement, a peritectic transformation occurs in the semi- HSS 3 grade during the solidification process (Figure 4d). This peritectic transformation is known to promote a new austenite phase from the decom- position of the previous delta ferrite H9B fer Reughers \x100}

Overview of work rolls microstructures for roughing stands. phase. As M2 C3 carbides in both Cr steel and semi-HSS grades 1 and 2 seem to start their precipitation close to or below the solidus temperature, with an increase of their amount with decreas- ing temperature, these carbides could be assume to be of eutectoid type. Only MC carbides found in semi-HSS 3 through the equilibrium diagram could be considered like real eutectic as they precipitated from the liquid.

Table 1 Roughing Mill Roll Grades — Analysis, Carbide Content and Hardness of Working Zone

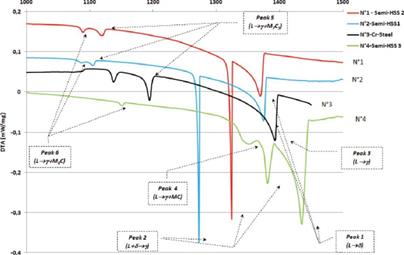

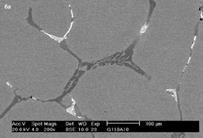

Thus in equilibrium conditions, semi-HSS grades 1 and 2 did not exhibit eutectic carbides, as M C 3 and the latter M 6C precipitated in the solid state. Furthermore, when the tempera- ture decreases in equilibrium condi- tions, all of the primary carbides (MC, MyC 3 and M6C) transform themselves closed to the Al point (Figures 4a—4d) in a partial or complete reaction, which leads to other types of carbides known as fine secondary carbides, such as M 23C6, M 2C and MC. Solidification Paths — Solidification paths were obtained from differential thermal analysis (DTA) tests. From this technique, a difference in energy is measured between the material to be tested and an inert reference mate- rial as a function of temperature, while both samples are submitted to a controlled temperature program. A phase transformation occurring in the studied material appears as an endothermic or an exothermic peak when the DTA cycle goes on. Figure 5 illustrates the results of DTA tests on the four grades during the cooling cycle, which starts from the melt down to room temperature at 5°C/minute. The solidification range was obtained while considering the liqui- dus and the solidus temperatures on the four studied grades. Table 3 gives the results obtained from the com- parison between equilibrium (from TC) and non-equilibrium (from DTA) conditions. SEM-EDS analyses (Figures 6a and b) performed after the DTA tests allow for the identification of the phases present at room temperature, such as the eutectics carbides and the matrix (mixture of martensite and retained austenite). Such a DTA solidification sequence had already been enhanced in previous work.8 *0 Only the starting points of M2C3 and M6C, which are considered as

Phase volume fractions with temperature in equilibrium conditions on Hi-Cr Steel (4a) and on semi-HSS 1 (4b). Phase volume fractions with temperature in equilibrium conditions on semi-HSS2 (4c) and on semi-HSS 3 (4d).

Figure 5

Solidification sequences on the four studied alloys during DTA cooling stage at 5°C/minute.

The semi-HSS 3 exhibits the higher liquidus tempera- eutectoid carbides in the equilibrium conditions, are illustrated in Table 2. It was observed that phase trans- formation range is shorter in the non-equilibrium con- ditions than that of the equilibrium conditions. From the comparison between Cr steel and semi-HSS grades, the following observations arise: The liquidus temperature of semi-HSS grades is always higher than that of the Cr steel, no matter what the con- ditions are from equilibrium or non-equilibrium. ture in the non-equilibrium conditions (l,428°C). The semi-HSS 3 grade contains MC eutectic carbides which precipitate at high temperature (1,353°C); as a consequence, no M2C3 are found in this alloy, and M6C precipitated earlier (1,l58°C) when compared to the related eutectic transformations on Cr-Steel, semi-HSS l and semi-HSS 2 grades. Eutectic M2 C3 and M6C carbides have achieved precipitation higher and more distinguishable tem- peratures in Cr steel than their equivalents in semi-HSS

Figure 6

Eutectic carbides network on Cr-Steel after DTA test: Fishbone-like M7C3 (grey) and fine-lamellar M6C (light) (6a); Complex M7C3/M 6C eutectic carbide in a Cr-Steel and related EDS mapping showing major elements of each phase

(Cr-rich M7C3 and Mo-rich M6C) (6b).

Table 2 Comparison of Phase Transformations Between Equilibrium and Non-Equilibrium Conditions

*End of the eutectic reaction from DTA tests

grades 1 and 2 in the DTA solidification sequence. From the comparison between equilibrium and non-equilibrium conditions, the following observations are made: Liquidus temperature obtained by DTA is always above that which was obtained from TC simulation. The first solid to precipitate in the non-equi- librium conditions is not correctly found by TC simulation, as it was the case of the three semi- HSS grades in which delta-ferrite precipitated first, instead of austenite. Eutectic carbides found in non-equilibrium conditions appear only in solid-state transfor- mations in the equilibrium conditions; thus, they must be considered as eutectoid carbides. The solidification range is always larger in the non-equilibrium conditions than that found in TC simulation, even if the first solid to form is the same in both conditions (see the case of chromium steel). Eutectic carbides obtained from the con- tinuous cooling of the melt are still present at room temperature, unlike the corresponding carbides found in the equilibrium conditions, as the latter disappear with solid-state trans- formation. In fact, M7C3 and M6C transform themselves respectively into M23C6 and M2C in the TC simulation. The differences observed between non-equi- librium and equilibrium simulations could be explained in several ways.

Hi-Cr steel (near the surface of the shell): Network of eutectic M7Cg (fishbone-like, grey) and M6C (light) carbides at grain boundaries, in a tempered martensitic matrix (7a). Semi-HSS 1 (close to the scrap diam- eter): Network of eutectic M7C3 (grey) and M6C (light) carbides at grain boundaries, in a tempered martensitic matrix (7b). Semi-HSS 2 (close to the scrap diameter): Network of eutectic M7C3 (bulk, grey) and M6C (light) at grain boundaries, in a tempered martensitic matrix (7c). Semi- HSS 3 (near the surface of the shell): Network of eutectic MC (Chinese script, light) and M6C (rod-like, light) carbides at grain boundaries, in a tempered martensitic matrix (7d).

Figure 8 delta-ferrite germ heterogeneous d th can promote non- Ca atione While equilibrium conditions assume a full diffusion of all the alloying elements, there is a segregation phenomenon in the non-equi- librium conditions, especially within the inter- dendritic space where strong carbide-forming elements, such as Nb, Mo, Cr that are gamma- incompatible, are rejected when the growing dendrite is of the austenite type.

Typical microstructures of studied rolls are shown in Figures 7a—d as obtained from a scan- ning electron microscope (SEM). The micro- structure of all rougher grades in the service conditions consists of a non-continuous net- Hot hardness (shore C) on Semi-HSS grades 2 and 3, Cr-Steel, and HSS for roughers (as a reference).

Both semi-HSS grades 2 and 3 seem to have similar work of eutectic carbides located at grain boundaries, with a tempered martensitic matrix. Such a distribution of carbides is common for HSS grades. '*0 and flat hot hardness behaviors, except for tempera- ture above 570°C, where hot hardness of semi-HSS grade 3 decreases slowly when that of semi-HSS grade 2 collapses. Such a levelling of the hot hardness above Hardness Features — Hot hardness had been deter- 570°C on semi-HSS 3, which is also observed on HSS for mined on three of the four studied grades with regard roughers, is probably due to the presence of a higher to HSS for roughers as a reference. amount of MC carbides on both compared to semi-HSS Figure 8 gives the hot hardness behavior of three grade 2 or Cr steel. studied grades and HSS rougher.

Gorrosion Behavior — Some static corrosion tests were performed in a liquid medium on Cr steel and semi- HSS 3 in a laboratory with the following conditions: 60°C; holding time from 4 to 27 hours; [Cl ] from 350 to 1,000 ppm and [HOC1 ] from 0 to 5 ppm. Figure 9 shows the results obtained on the surface of the samples at the end of the corrosion tests. Semi-HSS 3 appears to exhibit a less-corroded surface than Cr steel, as pits found on the previous are smaller than those found on the latter.

Overview of corrosion pits on Cr steel (left) and semi-HSS 3 (right) surfaces.

Roll Behavior in Service Layouts of Hot Strip Roughing Mills — In order to obtain a better understanding of the behavior aspects of roughing mill work roll grades, a short description of the different layouts found worldwide will be helpful for the reader (Figure 10). Many different kinds of roughing mills have been designed over the last 60 years. There are fully continu- ous HSMs with five to seven roughing stands and addi- tional edgers. This concept was born in the 1960s and was phased out after the first oil crisis of the early 1970s. In this layout, there is only a one-way rolling operation in the roughing mill. The distances between different roughing stands must be adapted to the length of the

Figure 10

Layouts of hot strip roughing mills. slab after each stand. Therefore, the whole roughing mill is considerably long. Another concept is the so-called three-quarter con- tinuous HSM, which includes at least a reversing rough- ing stand and one or several one-way roughing stands. The length of the roughing mill for this type is quite reduced when compared to the full-continuous mill. The next type, the semi-continuous HSM, includes just one reversing roughing mill combined with a vertical edger or a sizing press. Most of the recent new HSM built since 2000 are based on this concept. A twin-tan- dem reversing roughing mill has been realized as well, which combines the advantage of a short roughing mill and a high throughput. On the other hand, this solu- tion asks for a more sophisticated process control. The roughing stands may be built as 2-high or 4-high mills, one-way, reversing, single or tandem configuration. Situation in European Roughing MiIIS — A survey made in 25 western European HSM clearly highlights the dominant position of semi-HSS or HSS roughing mill grades in all types of roughing mills in Europe (Figures lla—b). Mill Demands With Respect to Work Roll Properties for Roug hing Stands — The interpretation of mill demands, with respect to work roll properties for rough- ing stands, may be summarized as follows: High roll bite based on high friction coefficient, allowing high reductions per pass without chattering or slippage, and consequently higher throughput with reduced heat loss of the product. High resistance of shell material against wear, ther- mal fatigue and oxidation/corrosion, resulting in low and homogeneous wear allowing longer rolling cam- paigns and reduced downtime. High heat and fire crack resistance, which stands for a smooth tiny fire crazing network preventing high damage caused by mill stalls. Perfect roll surface quality over long runs, which means no peeling, no banding and no microspalling during one campaign. High safety against roll failures generated by any kind of operation conditions including mill incidents, high thermal and mechanical loads, etc. The different roll grades used in roughing mills have been compared in Table 3 referring to these aspects.

High throughput for the HSM asks for a minimum number of passes in the roughing mill, which is of particular importance for semi-continuous HSMs. This means high reduction per pass, which is only possible with excellent roll biting behavior. It is well-known that roll bite is improved with lower carbide content and lower hardness of the working surface. Obviously, the semi-HSS grade and so far the new HSS grade for roughers have confirmed this basic rule. Both semi-HSS and HSS for roughers offer improved mechanical properties at elevated temperatures com- pared to any other roll type so far used in roughing mills. High temperature yield strength is mainly respon- sible for how far plastic deformation can be limited in the outer layer of the roll when the surface is heated to more than 600°C when it passes the roll gap in contact The advantage of better roll bite improves the possible throughput by more than 20 % compared to chrome steel work rolls. Pure wear perfor- mance of this new roll grade could be improved by 150 to 300 % compared to chrome he 2010 situation in five full continuous HSMs in Europe (a); in 20 HSMS (1/2 — 3/4 OF DSP mills) in Europe (b). with the hot slab. Corresponding thermal compressive steel in either reversing or one-way roughing stands. In many mills, campaign times could be doubled com-stresses are induced. The outstanding thermal resis- tance of these roll grades results in an extremely fine fire craving network compared to other grades under similar conditions. Normally, a low carbide content stands against high wear resistance. In case of the semi-HSS grade, the con- tradiction between low carbide content and high wear resistance has been eliminated by different factors. The semi-HSS alloy results in a completely different microstructure containing primary and secondary car- bides of MC-, M6C- and some M2C3-compositions. All of these carbides have a higher hardness compared to normal high-chrome iron or high-chrome steel compo- sitions. Even the M2 C3 carbide, which is a typical chro- mium carbide, becomes harder whenever it contains alloying elements such as molybdenum and vanadium. The very favorable roll bite behavior, based on low carbon content, allows for a strongly increased hardness and wear resistance of the homogeneous matrix for low and high temperature levels. In addition, wear due to high-temperature oxidation is minimized by a matrix composition offering high- temperature corrosion resistance. The full benefit of these characteristics is obtained by a sophisticated heat- treatment process, which stands for a homogeneous distribution of micro-carbides and high temperature resistance. The improved mechanical properties at elevated temperatures and the absence of a closed pri- mary carbide network guarantees a net improvement of shearing resistance and absence of micro-spallings. The combination of better roll bite and wear resis- tance offers important advantages to mill people. Examples from semi-continuous HSMs have proved that the standard seven-pass reversing operation in the roughing stand could be reduced to a standard five- pass practice. At the same time, the heat loss of the transfer bar is accordingly reduced. If the reversing rougher is the bottleneck of the whole hot mill process,pared to chrome steel work rolls without exceeding the allowable tolerance of roll gap geometry. It has become standard to achieve 50,000 to 80,000 tons per run for reversing roughing stands and five-pass reductions. A further important behavior of this roll grade is the smooth symmetric wear curve without any tendency for a dog-bone profile. For one-way roughing stands, more than 200,000 tons per campaign could be realized even in the last roughing stand of a full continuous mill. Regarding the roll cooling practice, no major modifica- tions were necessary to adapt both semi-HSS and HSS work roll grades for normal rolling operation. As far as semi-HSS is concerned, the semi-HSS 3 is confirmed as the optimum grade based on the inves- tigations developed in this paper, which could be con- firmed by numerous laboratory and industrial results. Regarding the HSS grade for roughing stands, indus- trial results in European HSM with a high percentage of stainless steel rolling have shown that wear perform- ance in terms of campaign time as well as tonnage per millimeter wear could be doubled compared to the traditional chrome steel grade. The consistency of roll gap geometry and roll surface quality has fulfilled all requirements. This grade has become a standard grade for stainless and special steels rolling.

Conclusions Semi-high-speed steel grades for roughing stand work rolls of HSMs have been presented in this paper. Different roll properties of particular interest for mill people have been discussed in comparison with other typical roll grades for roughing mills. The combina- tion of equilibrium diagrams and DTA tests could be helpful for the actual solidification sequence predic- tion in the industrial conditions on working rolls as the as-cast microstructure strongly influences subsequent mechanical properties.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Последнее изменение этой страницы: 2021-07-18; просмотров: 41; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 18.191.168.83 (0.13 с.) |

Jacqueline Lecomte-

Jacqueline Lecomte- Liége — Belgium qualitycontrol@mkb.be

Liége — Belgium qualitycontrol@mkb.be

F

F Figure 4

Figure 4

Figure 7

Figure 7

Delta ferrite that appears in the semi-HSS grades during non-equilibrium DTA tests could probably arise from inclusions (sul- phides or oxides), as they are known to be

Delta ferrite that appears in the semi-HSS grades during non-equilibrium DTA tests could probably arise from inclusions (sul- phides or oxides), as they are known to be