Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Reverse Circulation Drilling ⇐ ПредыдущаяСтр 10 из 10

To obtain information from large ore-bodies where minerals are not concentrated in narrow veins, reverse circulation drilling is used. Reverse circulation drilling is a fast, but inaccurate, exploration method, which uses near-standard percussion drilling equipment. The flushing media is introduced at the hole collar, in the annular space of a double-tubed drillstring, and pushed down to the bottom of the hole to flush the cuttings up through the inner tube. The drill cut-tings discharged on surface are sampled to identify variations in the mineralization of the rock mass. Reverse circulation drilling uses much heavier equipment than core drilling, and has thus a limited scope in depth.

Orebody Location

Every orebody has its own story, but there is often a sequence of findings. After a certain area catches the interest of the geologists, because of ancient mine works, mineral outcrops, or geological similarities, a decision is taken to prospect the area. If prospecting confirms the initial interest, some geophysical work might be carried out. If interest still persists, the next step would be to core drill a few holes to find out if there is any mineralization. To quantify the mineralization, and to define the shape and size of the orebody, then entails large investment to drill exploratory holes in the required patterns. At every step of the procedure, the geologists examine the information at hand, to recommend continuing the exploration effort. The objective is to be fairly certain that the orebody is economically viable, by providing a detailed knowledge of the geology for a clear financial picture. When probabilities come close to certainties, a decision might be taken to proceed with underground exploration. This is an expensive and time-consuming operation, involving sinking a shaft or an incline, and pilot mining drifts and galleries. Further drilling from underground positions, and other studies, will further establish the viability of the orebody. At this stage, a comprehensive feasibility study is undertaken covering capital requirements, returns on investment, payback period and other essentials, in order for the board of directors of the company to make the final decision. List of words

Exercises:

1) Give Ukrainian equivalents of the following words and word combinations: with a view to, outcrop of mineralization, a shallow layer of alluviums, to explore subsurface formations, physical properties of rock, metal bearing minerals, magnetic surveys

2) Give English equivalents of the following:

розробка, суцільне родовище, пошук нових суцільних родовищ, корінна підстильна порода, вихід на поверхню (оголення порід), локалізувати, визначати місце покладів мінералів, визначати глибину порід, пласт ґрунтових вод, рівень радіації

3) Fill the blanks with the necessary words: Surface exposure, magnetic surveys, exploratory drilling, core, prospecting, exploration 1. …involves searching a district for minerals with a view to further operation. 2. …is a term embracing geophysics, geochemistry and also drilling into the ground for obtaining samples from any depth. 3. A geologist prospecting a district is looking for … of minerals, by observing irregularities in colour, shape or rock composition. 4. …measure variations in the Earth’s magnetic properties of subsurface rock formations. 5. There are two main methods of … 6. …is an intact sample of the underground geology, which can be examined thoroughly by the geologist to determine the exact nature of the rock and any mineralization.

4) Quote the sentences in which these words and word combinations are used: to expose the bedrock, to penetrate deep into the ground, narrow veins, to take a decision, to come close (to), an expensive and time-consuming operation, a comprehensive feasibility study, to detect high-density minerals.

5) Give answers to the following questions: 1) What does the term “prospecting” involve? 2) What does the term “exploration” embrace? 3) For what purposes are different geophysical methods used? 4) What geophysical methods are described in the text? 5) Which are the main methods of exploratory drilling? 6) What (mining) technique is now widely used within the mining industry? How is it carried out? 7) In what case is reverse circulation drilling used? 8) What does feasibility study cover and when is it undertaken?

6) Tell what you know about: 1) Prospecting. 2) Geophysical exploration (Geophysical methods). 3) Exploratory drilling as one of exploration methods.

SUPPLEMENTARY READING Mining in Flat Orebodies

Nearly Horizontal Extraction Variations on room-and-pillar and longwall mining techniques have always been attractive propositions for mechanization, because of the near horizontality of such systems. Until recently, trackless equipment was limited to a minimum working headroom of 2 m or more. However, major developments in Polish copper mines and in gold and platinum mines in South Africa have spawned a new generation of thin-seam and narrow mining equipment from Atlas Copco that can work in substantially less space than previously thought possible. The Rocket Boomer S1 L, for instance, has a tramming height of just 1.3 m, yet can cover a face area of up to 29 sq m. Likewise, the Wagner ST 600LP, or Ratel, equipped with video cameras to assist the driver, has a height of only 1.56 m, but still carries a 6 t payload. Availability of such machines is already revolutionizing the design approach to mining flat orebodies.

Room and Pillar Room and pillar is designed for mining of flat, bedded deposits, of limited thickness. Examples are sedimentary deposits, like copper shale, limestone or sandstone containing lead, coal seams, salt and potash Wets, limestone and dolomite. The method recovers the mineralization in open stopes, leaving pillars of ore to support the hanging wall. To recover maximum ore. miners aim to leave the smallest possible pillars. The roof must remain intact, and rockbolts are used as rock reinforcement.

Rooms and pillars are normally arranged in regular patterns, and can be designed with circular pillars, square pillars, or elongated walls, separating the rooms. Classic room and pillar applies to flat, bedded deposits with moderate to large thickness, also to inclined deposits with larger thickness. Mining the orebody creates large open stopes, where trackless machines can travel on the flat floor. Orebodies with large vertical height are mined in horizontal slices, starting at the top and benching down in steps. Post room and pillar applies to inclined orebodies, of dip angle from 20 to 55 degrees, with large vertical height, where mined out space is back-filled. The fill keeps the rock mass stable, and serves as the work platform while mining the next ore slice. Step room and pillar is an adaptation of trackless minjng to orebodies with too steep a dip for rubber-tyred vehicles. Haulage drifts and stopes are angled across the dip, to create work areas with level floors, off which trackless equipment can work. mining advances downward, along the step room angle.

Classic Room and Pillar Very little development work is required to prepare flat-bedded deposits for room and pillar mining, because access for ore transport and communication is through the production stopes. Ore production in flat room and pillar uses the same drill/blast techniques as in normal drifting. Where geological conditions are favourable, large-capacity drilling rigs and loaders can be used.

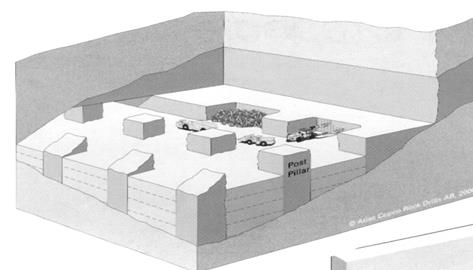

Figure1. Classic room and pillar layout

High orebodies are mined in slices, starting at the top, rockbolting the hanging wall from each bench. Standard crawler rigs are used for drilling vertical holes and conventional bench blasting. Horizontal drilling and flat benching is a more practical alternative, using the same drillrig. The blasted ore is loaded using diesel or cable-electric load-haul-dump machines, and, where height permits, dump trucks may be used between stope and dump.

Post Pillar Mining

Post pillar mining is a cross-breed of room and pillar and cut and fill stoping. Post pillar mining recovers the mineralization in horizontal slices, starting from a bottom slice, advancing upwards.

Figure 2. Post pillar mining layout.

Pillars are left inside the slope to support the roof. Mined-out stopes are backfilled with hydraulic tailings to allow the next slice to be mined, working off the fill surface. Pillars are extended through several layers of fill, so that the material conlributes to the support, permitting a high recovery rate. The sand fill allows the stope layout to be modified to suit variations in rock conditions and ore boundaries. Post pillar combines the advantages of flat-floor cut and fill, with the spacious stopes of room and pillar, while easy access to multiple production points favours efficient mechanization.

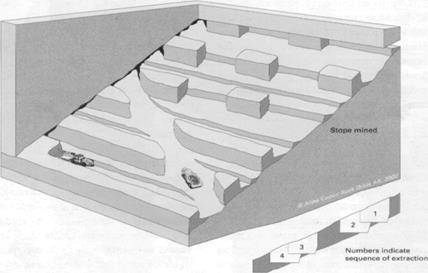

Step Room and Pillar Step room and pillar adapts the inclined orebody footwall for efficient use of trackless equipment in tabular deposits, with thickness from 2.0 to 5.0 m, and dip ranging from 15 to 30 degrees. Stopes and haulage-ways cross the dip of the orebody in a polar co-ordinate system, orienting the stopes at angles across the dip that can comfortably be travelled by trackless vehicles. Parallel transport routes cross the ore-body, to establish roadway access to stopes, and for trucking blasted ore to the shaft.

Figure 3. Step room and pillar layout

Stopes are attacked from the transport drifts, branching out at the pre- determined step-room angle. The stope is advanced forward, in a mode similar to drifting, until breakthrough into the next parallel transport drive.Next step is excavation of a similar drift, or side slash, one step down dip| adjacent to the first drive. This procedure is repeated, until the full roof span is achieved, and an elongated pillar left, parallel with the stopes. The next slope is attacked in the same way, and mining continues downward, step by step.

Longwall Mining Longwall mining applies to thin bedded deposits, with uniform thickness and large horizontal extension. Development involves excavation of a network of haulage drills, for access to production areas and transport of ore to shaft stations. As the mineralization extends over a large area, haulage drifts are paralleled by return airways, for ventilation of the workings. Haulage drills are usually arranged in regular patterns, and excavated in the ore.

Figure 4. Typical steep longwall layout

South African gold mines have developed their own techniques, using handheld pneumatic rock drills in reefs as thin as 1.0 m.. Pillars of timber or concrete are installed to support the roof in the very deep mines.

List of words

СПИСОК ВИКОРИСТАНОЇ ЛІТЕРАТУРИ:

1. Face Drilling, Sweden, 2004, p.136 2. Undergrounf Mining Equipment, Sweden, 2005, p.232 3. Asian Mining, Oct., 2001 4. Mining International, Finland, April, 2006 5. Asok Mallik, Stability Problems in Applied Mechanics, London, 2006, p.358 6. Rastogi M.P. Surface and Interfacial Science, NY, USA. 2006, p.435 7. Reliability, Safety and Hazard, edit H. Khushwaha, V.K. Raina, India, 2006, p.230 8. Rastogi M.P. Surface and Interfacial Science, NY, USA. 2006, p.320 9. Underground Mining Methods, 2004, p.29, p.12, p.17, p. 23, p.31 10. Dictionary of Contemporary English. Longman Pearson Education Limited, 1978, 2003 11. Modern English-Russian Polytechnical Dictionary, Moscow, 2003 12. М.Я. Баракова Английский язык для горных инженеров, Москва, «Высшая школа», 1987 13. М.Я. Баракова, Р.Л. Шендерова Английский язык для горных инженеров. Пособие по обучению чтению. Москва, «Высшая школа», 1987 14. М.Я. Баракова Английский язык для горных инженеров. Лексический минимум. Москва, «Высшая школа», 1987 15. Michael Swan and Catherine Walter. How English works. Oxford University Press, 2004 16. Asian Journal of Mining (AJM) July/Augest 2000 p.24-26, p.27-29 17. Cullen & Co. Государственное издательство физико-математической литературы. Москва, June, 2005 18. Great English-Ukrainian Dictionary. Донецьк, 2002 19. Англо-русский горный словарь под ред. проф., д.т.н. Л.И. Барона, Москва, 1987 ДЛЯ НОТАТОК

Тексти та завдання з дисципліни «НАУКОВА АНГЛІЙСЬКА МОВА» для аспірантів та здобувачів за напрямом «Гірництво» денної та заочної форм навчання

УКЛАДАЧІ: Надія Олексіївна Голівер, Олена Олексіївна Мельник

Реєстраційний №_______

Підписано до друку 2007р. Формат А5 Обсяг 75 стор. Тираж прим.

Видавничий центр КТУ, вул. ХХІІ Партз’їзду, 11, м. Кривий Ріг

|

|||||||

|

Последнее изменение этой страницы: 2016-06-29; просмотров: 310; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 18.221.239.148 (0.034 с.) |