Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Recommended battery tester: bm-210 or battery MATE or equivalent

TROUBLESHOOTING

19-2 BATTERY/CHARGING SYSTEM

SYSTEM LOCATION

REGULATOR/RECTIFIER

BATTERY

MAIN FUSE (30 A)

ALTERNATOR

SYSTEM DIAGRAM

MAIN FUSE (30 A)

ALTERNATOR

Y: Yellow

G: Green

R: Red

W: White

19-3 BATTERY/CHARGING SYSTEM

BATTERY

REMOVAL/INSTALLATION

Connect the positive cable first and then the negative cable.

Remove the left side cover (page 2-3). Turn the ignition switch OFF.

Disconnect the negative (–) cable [1] first and then the positive (+) cable [2].

Remove the bolt [3], battery holder plate [4] and battery [5].

Install the battery in the reverse order of removal.

TORQUE:

Battery holder plate bolt:

7.0 N·m (0.7 kgf·m, 5.2 lbf·ft) • Install the battery holder plate by aligning its hook with the slit of the battery case. • For digital clock setting procedure (page 20-7).

Align

[5]

VOLTAGE INSPECTION

Measure the battery voltage using a commercially available digital multimeter.

VOLTAGE (20°C/68°F):

Fully charged: 13.0 – 13.2 V Under charged: Below 12.3 V

If the battery voltage is below 12.3 V, charge the battery.

BATTERY TESTING

Refer to the instructions that are appropriate to the battery testing equipment available to you.

TOOL:

Battery tester BM-210 or BATTERY MATE or equivalent

CHARGING SYSTEM INSPECTION

CURRENT LEAKAGE INSPECTION

• When measuring current using a tester, set it to a high range, and then bring the range down to an appropriate level. Current flow higher than the range

SPECIFIED CURRENT LEAKAGE: 0.34 mA max.

19-4 BATTERY/CHARGING SYSTEM

• To prevent a short, make absolutely certain which are the positive (+) and negative (–) terminal or cable.

• Do not disconnect the battery or any cable in the charging system without first turning the ignition

With the headlight high beam, measure the voltage on

the multimeter when the engine runs at 5,000 min-1 (rpm).

STANDARD:

Measured BV < Measured CV < 15.5 V • BV = Battery Voltage • CV = Charging Voltage

ALTERNATOR CHARGING COIL

INSPECTION

Remove the left side cover (page 2-3). Disconnect the alternator 3P connector [1].

Measure the resistance between the Yellow wire terminals of the alternator side connector.

STANDARD: 0.1 – 1.0 Ω (20°C/68°F)

Check for continuity between each wire terminal of the alternator/stator side connector and ground.

There should be no continuity.

Replace the alternator stator if the resistance is out of specification, or if any wire has continuity to ground.

19-5 BATTERY/CHARGING SYSTEM

REGULATOR/RECTIFIER

REMOVAL/INSTALLATION

Remove the bolts [2] and regulator/rectifier [3] from the reserve tank stay.

Install the regulator/rectifier in the reverse order of removal.

[1]

SYSTEM INSPECTION

Remove the right fuel tank shroud (page 2-4).

Turn the ignition switch OFF. Disconnect the regulator/rectifier 5P connector [1], and check it for loose contacts or corroded terminals.

If the charging voltage reading (page 19-5) is out of the specification, check the following at the wire harness side connector [1]:

If all components of the charging system are normal and there are no loose connections at the regulator/ rectifier connector, replace the regulator/rectifier unit.

[1]

[1]

19-6 LIGHTS/METERS/SWITCHES

SERVICE INFORMATION···························20-2

SYSTEM LOCATION···································20-2

HEADLIGHT ················································20-3

POSITION LIGHT ········································20-3

TURN SIGNAL LIGHT·································20-4

BRAKE/TAILLIGHT·····································20-5

SPEEDOMETER··········································20-5 VS SENSOR ················································20-8

HIGH COOLANT TEMPERATURE INDICATOR ·················································20-9

IGNITION SWITCH····································20-10

HANDLEBAR SWITCH·····························20-11

BRAKE LIGHT SWITCH ···························20-12

NEUTRAL SWITCH ··································20-12

SIDESTAND SWITCH·······························20-13

CLUTCH SWITCH·····································20-14

FUEL GAUGE/FUEL LEVEL SENSOR····················································20-14

HORN ························································20-15 TURN SIGNAL RELAY ·····························20-15

20-1 LIGHTS/METERS/SWITCHES

SERVICE INFORMATION

GENERAL

• Note the following when replacing the halogen headlight bulb. – Wear clean gloves while replacing the bulb. Do not put fingerprints on the headlight bulb, as they may create hot spots on the bulb and cause it to fail. – If you touch the bulb with your bare hands, clean it with a cloth moistened with alcohol to prevent its early failure. • Be sure to install the dust cover after replacing the headlight bulb. • A halogen headlight bulb becomes very hot while the headlight is ON, and remains hot for a while after it is turned OFF. Be sure to let it cool down before servicing. • Check the battery condition before performing any inspection that requires proper battery voltage. • A continuity test can be made with the switches installed on the motorcycle. • The following color codes are used throughout this section.

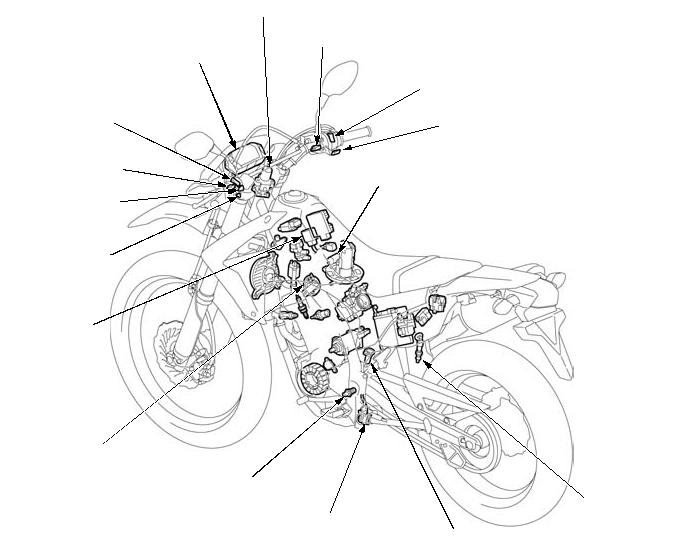

SYSTEM LOCATION

DIMMER SWITCH

CLUTCH SWITCH

HORN SWITCH

TURN SIGNAL

SWITCH

TURN SIGNAL

RELAY

HORN

IGNITION SWITCH

FRONT BRAKE LIGHT SWITCH

SPEEDOMETER

ENGINE STOP SWITCH

STARTER SWITCH

FUEL LEVEL SENSOR

NEUTRAL SWITCH

SIDESTAND SWITCH

VS SENSOR

REAR BRAKE LIGHT SWITCH

20-2 LIGHTS/METERS/SWITCHES

HEADLIGHT

BULB REMOVAL/INSTALLATION

Remove the headlight cowl (page 2-5).

TORQUE:

Headlight unit mounting screw: 1.2 N·m (0.1 kgf·m, 0.9 lbf·ft)

[1]

[2]

POSITION LIGHT

BULB REMOVAL/INSTALLATION

Remove the headlight cowl (page 2-5).

Pull out the bulb socket [1] from the headlight case.

Remove the bulb [2] from the socket.

Installation is in the reverse order of removal.

[2]

[1]

20-3 LIGHTS/METERS/SWITCHES

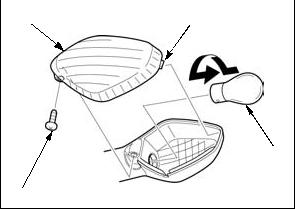

TURN SIGNAL LIGHT

BULB REMOVAL/INSTALLATION

[4]

[1]

FRONT TURN SIGNAL UNIT REMOVAL/INSTALLATION

Remove the headlight cowl (page 2-5).

Disconnect the front turn signal 2P connector [1].

– Right side: Light blue – Left side: Orange

Release the wire from the wire band [2]. Left side only: Release the wire from the wire band [3].

Remove the nut [4] and front turn signal unit [5]. Installation is in the reverse order of removal.

TORQUE:

Turn signal unit mounting nut: 21 N·m (2.1 kgf·m, 15 lbf·ft)

Align the flats of the turn signal unit and speedometer stay.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Последнее изменение этой страницы: 2016-04-08; просмотров: 590; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 3.145.131.238 (0.145 с.) |