Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Instruction and Maintenance Manual

ZHEJIANG QIANJIANG MOTORCYCLE CO., LTD. Contents PrefaceЎ¤ - 1 - Preparatory DataЎ¤ - 2 - Inspection/Adjustment - 15 - Check and Maintenance of Body Ў¤ - 32 - I Braking System Ў¤Ў¤ - 34 - 1.1 Maintenance InstructionЎ¤ - 34 - 1.2 Fault diagnosis - 35 - 1.3 Front Hydraulic BrakeЎ¤ - 36 - 1.4 Back liquid brakeЎ¤ - 38 - II Vehicle Housing Ў¤ - 42 - III Front Wheel/Front Suspension Ў¤ - 45 - 3.1 Preparatory DataЎ¤ - 45 - 3.2 Fault diagnosis - 45 - 3.3 Front wheel - 47 - 3.4 Direction handleЎ¤ - 49 - 3.5 Front forkЎ¤ - 49 - IV Rear Wheel/Rear Suspension Ў¤ - 54 - 4.1 Preparatory DataЎ¤ - 54 - 4.2 Fault Diagnosis - 55 - 4.3 Rear wheel - 56 - 4.4 Rear Shock Absorber - 57 - 4.5 Rear Swing ArmЎ¤Ў¤ - 58 - 4.6 Drive ChainЎ¤ - 59 - V Storage Battery/Charging System Ў¤Ў¤ - 62 - 5.1 Preparatory DataЎ¤ - 62 - 5.2 Fault Diagnosis - 63 - 5.3 Storage BatteryЎ¤ - 64 - 5.4 Charging SystemЎ¤Ў¤ - 65 - 5.5 Voltage-current Regulator - 66 - 5.6 Alternator Charging Coil - 67 - 5.7 alternator light coil - 67 - 5.8 disassembly of alternator - 68 - VI Ignition System Ў¤Ў¤ - 71 - 6.1 Preparatory DataЎ¤ - 71 - 6.2 Fault Diagnosis - 72 - 6.3 Ignition System InspectionЎ¤ - 73 - 6.4 CDI AssemblyЎ¤ - 75 - 6.5 Ignition Coil - 75 - 6.6 Trigger - 76 - VIIStarting System Ў¤Ў¤ - 78 - 7.1 Preparatory DataЎ¤ - 78 - 7.2 Fault Diagnosis - 79 - 7.3 Starting Motor - 79 - 7.4 Starting RelayЎ¤ - 81 - VIIIBulbs/Switches/Instruments - 82 - 8.1 Preparatory DataЎ¤ - 82 - 8.2 Fault Diagnosis - 82 - 8.3 Headlamp Bulb Replacement - 83 - 8.4 Front Turn Signal Lamp Bulb Replacement - 84 - 8.5 Taillight/license plate lamp/rear turn-lamp bulb replacement - 84 - 8.6 Instrument - 85 - 8.7 Main SwitchЎ¤ - 85 - 8.8 HornЎ¤ - 86 - 8.9 Handle switchЎ¤ - 86 - Engine Inspection and Maintenance Ў¤ - 87 - IX Lubricating System Ў¤Ў¤ - 89 - 9.1 Preparatory DataЎ¤ - 89 - 9.2 Fault Diagnosis - 89 - 9.3 Oil PumpЎ¤ - 90 - X Cooling system Ў¤Ў¤ - 93 - 10.1 Preparatory dataЎ¤ - 93 - 10.2 Fault diagnosis - 93 - 10.3 Water pumpЎ¤ - 94 - XI Cylinder Head Ў¤ - 97 - 11.1 Preparatory DataЎ¤ - 97 - 11.2 Fault Diagnosis - 98 - 11.3 Cylinder HeadЎ¤ - 98 - XII Cylinder Block and Piston Ў¤ - 107 - 12.1 Preparatory DataЎ¤ - 107 - 12.2 Fault Diagnosis - 108 - 12.3 Cylinder HeadЎ¤ - 108 - XIII Crankcase Ў¤ - 113 - 13.1 Preparatory DataЎ¤ - 113 - 13.2 Fault Diagnosis - 114 - 13.3 CrankcaseЎ¤ - 115 - 13.4 ClutchЎ¤ - 116 - 13.5 Gearshift mechanismЎ¤Ў¤ - 121 - 13.6 Crankcase connecting rod combinationЎ¤ - 122 - 13.7 Variable speed chamber - 125 - Exhaust System Inspection and Maintenance Ў¤ - 128 - XV Emission Control System Ў¤Ў¤ - 129 - 15.1 Emission Control System GuaranteeЎ¤ - 129 - 15.2 Regular maintenance guidelines - 129 - 15.3 Emission Control System Mechanical Functions - 130 - 15.4 Catalyst conversion systemЎ¤Ў¤ - 131 - 15.5 Solutions to Idle Exhaust Exceeding Specified ValueЎ¤ - 132 - Inspection and Maintenance of EFI System Ў¤Ў¤ - 133 - XVIEFI System Description Ў¤ - 134 - 16.1 Introduction to EFI System of finished enginecycleЎ¤ - 134 - 16.2 EFI system parts - 134 - 16.3 Troubleshooting diagnosis - 146 - 16.4 Common troubleshootingЎ¤ - 153 - 16.4.3 Concise troubleshootingЎ¤ - 154 - QJ125GY-16A circuit diagram Ў¤Ў¤ i

Preface

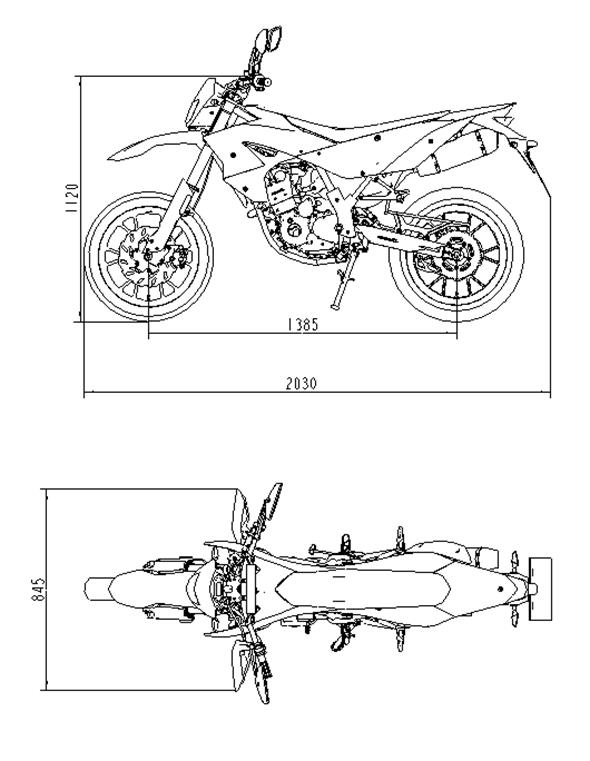

The Instruction and Maintenance Manual contains an introductory description of maintenance on QJ125GY-16A motorcycle. Preparatory data include attentions that shall be paid on all the maintenance operations in the Instruction and Maintenance Manual. Please read the manual carefully before operation. Check and adjustment contains main aspects for inspection and adjustment, safety of the vehicle, performance and maintenance of each component. This shall be started from the time of periodical inspection.

The parts following Chapter One demonstrate the main point of disassembly, installation and check of electrics parts, finished vehicle, engine and other components. System diagrams, breakdown drawings, fault diagnosis, maintenance and other explanatory contents are presented before each part. Note: The parts which are not explained separately in the manual apply to both of the motorcycles. For any pattern and structure change of the motorcycle, or any difference between the product and pictures, drawings and instructions in the manual, the product shall prevail. The product is subject to changes without prior personal notice.

ZHEJIANG QIANJIANG MOTORCYCLE CO., LTD. Finished Automobile Institute Preparatory Data General Safety Maintenance Rules Specification Table Fault Diagnosis General Safety Carbon monoxide (CO) When it is necessary to start the engine, please make sure the operation area is well ventilated. Never run the engine in an enclosed place. Attention

It is necessary to run the engine in an open area. To run the engine in an enclosed site, ventilation system shall be used. Gasoline Operate in well-ventilated site. No fire or smoking is allowed in operation site and gasoline storage place. Storage Battery Electrolyte in the storage battery has sulfuric acid, so leave eyesЎўskin and clothes away from it. Once got electrolyte on our skin or clothes, you will have to wash them by fresh water thoroughly; once into our eyes, to see a doctor immediately is necessary. Special Tool When disassembly and installation is in process, general tools and special tools should be selected correctly. When it is time to use the special, the general can not be substitution. Besides, appropriate power is welcomed to avoid the damage of components. High Temperature Burn Tips: Do not be burned by engine, exhaust pipe,silencer and other components with high temperature. When operating together with others, youЎЇd better look after each other and keep a way for safety. Maintenance Rules While repairing and servicing, use tools of metric system as possible. Incorrect tools may damage the motorcycle. Before taking down or opening protecting plate for repair work, please clean the dirt on the external surfaces of components or combination parts and prevent the dirt from falling into engine, chassis or braking system

The complicated assemblies such as transmission case shall be put in proper assembling order for easy assembly in the future.

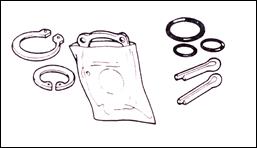

Pay special attention to the key fitting position before disassembly. The components that are not used any more shall be replaced on time before disassembly.

Fill lubricating grease into the groove during oil seal installation. Check if the oil seal is smooth and if there is any damage to it.

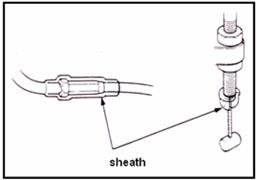

Installation of rubber hose (fuel, vacuum, or coolant): insert its end into bottom of connector so that there is enough room for the hose clamp to grip the connector. Install the rubber or plastic dust cover back to its originally designed position

Specifications (QJ125GY-16A)

QJ125GY-16A

Fault Diagnosis

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Последнее изменение этой страницы: 2016-04-08; просмотров: 634; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 3.133.137.17 (0.012 с.) |

After disassembly and before measuring friction, please clean the components and blow them with compressed air.

After disassembly and before measuring friction, please clean the components and blow them with compressed air. ЎЄBending or Warping are forbidden in operation, otherwise tough operation or advanced damage will be caused.

ЎЄBending or Warping are forbidden in operation, otherwise tough operation or advanced damage will be caused. Plastic parts may age and deteriorate, which are apt to be damaged by solvent or oil. Check before re-installation and replace if necessary.

Plastic parts may age and deteriorate, which are apt to be damaged by solvent or oil. Check before re-installation and replace if necessary. To loose component with many assembling units, it shall start from external to internal and loosen smaller assemblies first.

To loose component with many assembling units, it shall start from external to internal and loosen smaller assemblies first.

Length of bolts and screws are different for assembly components and protecting plates. They shall be installed at correct positions. If confused, just put the bolt in the hole and see if it matches.

Length of bolts and screws are different for assembly components and protecting plates. They shall be installed at correct positions. If confused, just put the bolt in the hole and see if it matches.

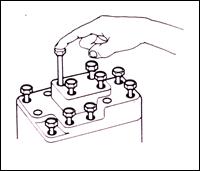

Disassembly of ball bearing: use a tool to push against one or two (internal and external) bearing races. If the force works only on one bearing race (whatever internal or external), it may be damaged when the bearing is disassembled, in which case, it must be replaced

Disassembly of ball bearing: use a tool to push against one or two (internal and external) bearing races. If the force works only on one bearing race (whatever internal or external), it may be damaged when the bearing is disassembled, in which case, it must be replaced