Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Properties of wood materialsСтр 1 из 5Следующая ⇒ WOOD MATERIALS Wood is a porous and fibrous structural tissue found in the stems and roots of trees and other woody plants. It is an organic material, a natural composite of cellulose fibers that are strong in tension and embedded in a matrix of lignin that resists compression. Wood is sometimes defined as only the secondary xylem in the stems of trees, or it is defined more broadly to include the same type of tissue elsewhere such as in the roots of trees or shrubs. In a living tree it performs a support function, enabling woody plants to grow large or to stand up by themselves. It also conveys water and nutrients between the leaves, other growing tissues, and the roots. Wood may also refer to other plant materials with comparable properties, and to material engineered from wood, or wood chips or fiber. Wood has been used for thousands of years for fuel, as a construction material, for making tools and weapons, furniture and paper, and as a feedstock for the production of purified cellulose and its derivatives, such as cellophane and cellulose acetate. In 2005, the growing stock of forests worldwide was about 434 billion cubic meters, 47% of which was commercial. As an abundant, carbon-neutral renewable resource, woody materials have been of intense interest as a source of renewable energy. In 1991 approximately 3.5 billion cubic meters of wood were harvested. Dominant uses were for furniture and building construction.

HEARTWOOD Heartwood (or duramen) is wood that as a result of a naturally occurring chemical transformation has become more resistant to decay. Heartwood formation is a genetically programmed process that occurs spontaneously. Some uncertainty exists as to whether the wood dies during heartwood formation, as it can still chemically react to decay organisms, but only once.

Heartwood is often visually distinct from the living sapwood, and can be distinguished in a cross-section where the boundary will tend to follow the growth rings. For example, it is sometimes much darker. However, other processes such as decay or insect invasion can also discolor wood, even in woody plants that do not form heartwood, which may lead to confusion. Sapwood (or alburnum) is the younger, outermost wood; in the growing tree it is living wood, and its principal functions are to conduct water from the roots to the leaves and to store up and give back according to the season the reserves prepared in the leaves. However, by the time they become competent to conduct water, all xylem tracheids and vessels have lost their cytoplasm and the cells are therefore functionally dead. All wood in a tree is first formed as sapwood. The more leaves a tree bears and the more vigorous its growth, the larger the volume of sapwood required. Hence trees making rapid growth in the open have thicker sapwood for their size than trees of the same species growing in dense forests. Sometimes trees (of species that do form heartwood) grown in the open may become of considerable size, 30 cm (12 in) or more in diameter, before any heartwood begins to form, for example, in second-growth hickory, or open-grown pines. The term heartwood derives solely from its position and not from any vital importance to the tree. This is evidenced by the fact that a tree can thrive with its heart completely decayed. Some species begin to form heartwood very early in life, so having only a thin layer of live sapwood, while in others the change comes slowly. Thin sapwood is characteristic of such species as chestnut, black locust, mulberry, osage-orange, and sassafras, while in maple, ash, hickory, hackberry, beech, and pine, thick sapwood is the rule. Others never form heartwood. No definite relation exists between the annual rings of growth and the amount of sapwood. Within the same species the cross-sectional area of the sapwood is very roughly proportional to the size of the crown of the tree. If the rings are narrow, more of them are required than where they are wide. As the tree gets larger, the sapwood must necessarily become thinner or increase materially in volume. Sapwood is relatively thicker in the upper portion of the trunk of a tree than near the base, because the age and the diameter of the upper sections are less. When a tree is very young it is covered with limbs almost, if not entirely, to the ground, but as it grows older some or all of them will eventually die and are either broken off or fall off. Subsequent growth of wood may completely conceal the stubs which will however remain as knots. No matter how smooth and clear a log is on the outside, it is more or less knotty near the middle. Consequently, the sapwood of an old tree, and particularly of a forest-grown tree, will be freer from knots than the inner heartwood. Since in most uses of wood, knots are defects that weaken the timber and interfere with its ease of working and other properties, it follows that a given piece of sapwood, because of its position in the tree, may well be stronger than a piece of heartwood from the same tree. It is remarkable that the inner heartwood of old trees remains as sound as it usually does, since in many cases it is hundreds, and in a few instances thousands, of years old. Every broken limb or root, or deep wound from fire, insects, or falling timber, may afford an entrance for decay, which, once started, may penetrate to all parts of the trunk. The larvae of many insects bore into the trees and their tunnels remain indefinitely as sources of weakness. Whatever advantages, however, that sapwood may have in this connection are due solely to its relative age and position. If a tree grows all its life in the open and the conditions of soil and site remain unchanged, it will make its most rapid growth in youth, and gradually decline. The annual rings of growth are for many years quite wide, but later they become narrower and narrower. Since each succeeding ring is laid down on the outside of the wood previously formed, it follows that unless a tree materially increases its production of wood from year to year, the rings must necessarily become thinner as the trunk gets wider. As a tree reaches maturity its crown becomes more open and the annual wood production is lessened, thereby reducing still more the width of the growth rings. In the case of forest-grown trees so much depends upon the competition of the trees in their struggle for light and nourishment that periods of rapid and slow growth may alternate. Some trees, such as southern oaks, maintain the same width of ring for hundreds of years. Upon the whole, however, as a tree gets larger in diameter the width of the growth rings decreases. Different pieces of wood cut from a large tree may differ decidedly, particularly if the tree is big and mature. In some trees, the wood laid on late in the life of a tree is softer, lighter, weaker, and more even-textured than that produced earlier, but in other trees, the reverse applies. This may or may not correspond to heartwood and sapwood. In a large log the sapwood, because of the time in the life of the tree when it was grown, may be inferior in hardness, strength, and toughness to equally sound heartwood from the same log. In a smaller tree, the reverse may be true.

Strength Physically, wood is strong and stiff but, compared to a material like steel, it's also light and flexible. It has another interesting property too. Metals, plastics, and ceramics tend to have a fairly uniform inner structure and that makes them isotropic: they behave exactly the same way in all directions. Wood is different due to its annual-ring-and-grain structure. You can usually bend and snap a small, dead, tree branch with your bare hands, but you'll find it almost impossible to stretch or compress the same branch if you try pulling or pushing it in the opposite direction. The same holds when you're cutting wood. If you've ever chopped wood with an ax, you'll know it splits really easily if you slice with the blade along the grain, but it's much harder to chop the opposite way (through the grain). We say wood is anisotropic, which means a lump of wood has different properties in different directions.

That's not just important to someone chopping away in the woodshed: it also matters when you're using wood in construction. Traditional wooden buildings are supported by huge vertical poles that transmit forces down into the ground along their length, parallel to the grain. That's a good way to use wood because it generally has high compressive strength (resistance to squeezing) when you load it in the same direction as the grain. Wooden poles are much weaker placed horizontally; they need plenty of support to stop them bending and snapping. That's because they have lower tensile strength (resistance to bending or pulling forces across the grain). Not all woods are the same, however. Oak has much higher tensile strength than many other woods, which is why it was traditionally used to make the heavy, horizontal beams in old buildings. Other factors such as how well seasoned (dry) a piece of wood is (as discussed below) and how dense it is also affect its strength. Durability One of the best things about wood is how long it lasts. Browsing through the daily news, you'll often read that archeologists have unearthed the buried remains of some ancient wooden article—a wooden tool, perhaps, or a simple rowboat or the remnants of a huge building—that are hundreds or even thousands of years old. Providing a wooden object is properly preserved (something else we discuss later), it will easily outlast the person who made it. But just like that person, a wooden object was once a living thing—and it's a natural material. Like other natural materials, it's subject to the natural forces of decay through a process known as rotting, in which organisms such as fungi and insects such as termites and beetles gradually nibble away the cellulose and lignin and reduce wood to dust and memories.

Wood and water Wood has many other interesting characteristics. It's hygroscopic, which means that, just like a sponge, it absorbs water and swells up in damp conditions, giving out the water again when the air dries and the temperature rises. If, like mine, your home has wooden windows, you'll probably notice that they open much more easily in summer than in winter, when the damp outdoor conditions make them swell into the frames (not necessarily such a bad thing, since it helps to keep out the cold). Why does wood absorb water? Remember that the trunk of a tree is designed to carry water from the roots to the leaves: it's pretty much a water superhighway. A freshly cut piece of "green" wood typically contains a huge amount of hidden water, making it very difficult to burn as firewood without a great deal of smoking and spitting. Some kinds of wood can soak up several times their own weight of water, which is absorbed inside the wood by the very same structures that transported water from the roots of the tree to the leaves when the tree was a living, growing plant.

Environmentally friendly Wood was one of the first natural materials people learned to use, and it's never lost its popularity. These days, it's particularly prized for being a natural and environmentally friendly product. Forestry is a rare example of something that has the potential to be completely sustainable: in theory, if you plant a new tree for every old tree you cut down, you can go on using wood forever without damaging the planet. In practice, you need to replace like with like and forestry is not automatically sustainable, whatever papermakers like us to believe. A brand new tree has much less ecological value than a mature tree that's hundreds of years old so planting a thousand saplings may be no replacement for felling just a handful of ancient trees. Logging can be hugely environmentally damaging, whether it involves clearcutting a tropical rainforest or selectively felling mature trees in old-growth temperate woodland. Some of the processes and chemicals used in forestry and woodworking are also environmentally damaging; chlorine, used to bleach wood fibers to make paper, can cause water pollution in rivers, for example. But on the positive side, growing trees remove carbon dioxide from the atmosphere and planting more of them is one way to reduce the effects of climate change.

STAGE ONE:HARVESTING

Growing plants for food is called agriculture; growing trees for human use is silviculture—and the two things have a great deal in common. Wood is a plant crop that must be harvested just like any other, but the difference is how long trees take to grow, often many years or even decades. How wood is harvested depends on whether trees are growing in plantations (where there are hundreds or thousands of the same species, generally of similar age) or in mature forests (where there's a mixture of different species and trees of widely differing ages).

Planted trees may be grown according to a precise plan and clear-cut (the entire forest is felled) when they reach maturity. A drastic approach like that makes sense if the trees are a fast-growing species planted specifically for use as biomass fuel, for example. Individual trees can also be selectively felled from mixed forests and either dragged away by machine or animal or even (if it makes economic and environmental sense) hauled upward by helicopter, which avoids damaging other nearby trees. Sometimes trees have their bark and small branches removed in the forest before being hauled away to a lumber yard for further processing, though they can also be removed intact, with the entire processing done offsite. It all depends on the value of the tree, the growing conditions, how far away the lumber yard is, and how easy the tree is to transport. Another interesting form of forestry is called coppicing, which involves removing long, thin, low-growing branches from trees such as hazel and willow in a careful and respectful way that does no long-term damage. Stage Three: On Site At the chosen site, the logs are debarked and bucked, or cut to the required length. Then they are cut into boards, using equipment such as circular saws and bandsaws. This is called ‘conversion’. The first stage of conversion is a process called ‘breaking down’ - which means rough sawing. The second stage is called ‘re-sawing’ and refers to more precise cutting and finishing, such as planing and further machining.

Two types of rough sawing can be used in the breaking down process - through sawn and quarter sawn.

The ends of each log is trimmed to ensure they are straight and cut into boards. Large circular saws are then used to further-process the boards, removing the curved edges. Each processed piece of wood now looks like a board. Stage Four: Seasoning Seasoning of natural wood is the process of removing excess water/moisture content. When a tree is felled, it still contains a large proportion of water/moisture – usually between forty to fifty per cent water content. Water is held inside a tree in two ways: 1. Free Water: Water that is held in the vessels and cells in order to distribute nutrients inside the tree. 2. Cell water: Also known as ‘bound’ water, is an essential part of the tree’s cell walls. During the seasoning process, a tree loses its free water and a high proportion of its cell water and as a result, is less likely to warp or deform. Wood that has not been seasoned and still has a high water content is called ‘green wood’ and can be more difficult to work with because it has a tendency to change shape. Engineered wood Alternatively, it is also possible to manufacture similar engineered bamboo from bamboo; and similar engineered cellulosic products from other lignin-containing materials such as rye straw, wheat straw, rice straw, hemp stalks, kenaf stalks, or sugar cane residue, in which case they contain no actual wood but rather vegetable fibers. Flat pack furniture is typically made out of man-made wood due to its low manufacturing costs and its low weight. Plywood Plywood, a wood structural panel, is sometimes called the original engineered wood product. Plywood is manufactured from sheets of cross-laminated veneer and bonded under heat and pressure with durable, moisture-resistant adhesives. By alternating the grain direction of the veneers from layer to layer, or “cross-orienting”, panel strength and stiffness in both directions are maximized. Other structural wood panels include oriented strand board and structural composite panels. Fibreboard Medium-density fibreboard, is made by breaking down hardwood or softwood residuals into wood fibres, combining it with wax and a resin binder, and forming panels by applying high temperature and pressure.

Particle board Particle board is manufactured from wood chips, sawmill shavings, or even sawdust, and a synthetic resin or other suitable binder, which is pressed and extruded. Oriented strand board, also known as flakeboard, waferboard, or chipboard, is similar but uses machined wood flakes offering more strength. Particle board is cheaper, denser and more uniform than conventional wood and plywood and is substituted for them when cost is more important than strength and appearance. A major disadvantage of particleboard is that it is very prone to expansion and discoloration due to moisture, particularly when it is not covered with paint or another sealer. Oriented strand board Oriented strand board (OSB) is a wood structural panel manufactured from rectangular-shaped strands of wood that are oriented lengthwise and then arranged in layers, laid up into mats, and bonded together with moisture-resistant, heat-cured adhesives. The individual layers can be cross-oriented to provide strength and stiffness to the panel. However, most OSB boards are delivered with more strength in one direction. The wood strands in the outmost layer on each side of the board are normally aligned into the strongest direction of the board. Arrows on the product will often identify the strongest direction of the board (When bought in most cases the height (The longest dimension) of the board). Produced in huge, continuous mats, OSB is a solid panel product of consistent quality with no laps, gaps or voids. OSB is delivered in various dimensions, strengths and levels of water resistance. Laminated timber[edit] Glued laminated timber (glulam) is composed of several layers of dimensional timber glued together with moisture-resistant adhesives, creating a large, strong, structural member that can be used as vertical columns or horizontal beams. Glulam can also be produced in curved shapes, offering extensive design flexibility. Laminated veneer Laminated veneer lumber (LVL) is produced by bonding thin wood veneers together in a large billet. The grain of all veneers in the LVL billet is parallel to the long direction. The resulting product features enhanced mechanical properties and dimensional stability that offer a broader range in product width, depth and length than conventional lumber. LVL is a member of the structural composite lumber (SCL) family of engineered wood products that are commonly used in the same structural applications as conventional sawn lumber and timber, including rafters, headers, beams, joists, rim boards, studs and columns. Laminated strand Laminated strand lumber (LSL) and oriented strand lumber (OSL) are manufactured from flaked wood strands that have a high length-to-thickness ratio. Combined with an adhesive, the strands are oriented and formed into a large mat or billet and pressed. LSL and OSL offer good fastener-holding strength and mechanical connector performance and are commonly used in a variety of applications, such as beams, headers, studs, rim boards, and millwork components. These products are members of the structural composite lumber (SCL) family of engineered wood products. LSL is manufactured from relatively short strands—typically about 1 foot long—compared to the 2 foot to 8 foot long strands used in PSL. Beams I-joists and wood I-beams are "I"-shaped structural members designed for use in floor and roof construction. An I-joist consists of top and bottom flanges of various widths united with webs of various depths. The flanges resist common bending stresses, and the web provides shear performance. I-joists are designed to carry heavy loads over long distances while using less lumber than a dimensional solid wood joist of a size necessary to do the same task. Trusses Roof trusses and floor trusses are structural frames relying on a triangular arrangement of webs and chords to transfer loads to reaction points. For a given load, long wood trusses built from smaller pieces of lumber require less raw material and make it easier for AC contractors, plumbers, and electricians to do their work, compared to the long 2x10s and 2x12s traditionally used as rafters and floor joists.

THERMALLY MODIFIED WOOD Thermally modified wood is wood that has been modified by a controlled pyrolysis process of wood being heated (> 180 °C) in absence of oxygen inducing some chemical changes to the chemical structures of cell wall components (lignin, cellulose and hemicellulose) in the wood in order to increase its durability. Low oxygen content prevents the wood from burning at these high temperatures. Several different technologies are introduced using different media including nitrogen gas, steam and hot oil. TYPES · Extruded – made by being forced through an opening in a steel die, with a very consistent size and shape. · Wire-cut – cut to size after extrusion with a tensioned wire which may leave drag marks · Moulded – shaped in moulds rather than being extruded · Machine-moulded - clay is forced into moulds using pressure · Handmade - clay is forced into moulds by a person · Dry-pressed - similar to soft mud method, but starts with a much thicker clay mix and is compressed with great force. Categorized by use: · Common or building – A brick not intended to be visible, used for internal structure · Face – A brick used on exterior surfaces to present a clean appearance · Hollow – not solid, the holes are less than 25% of the brick volume · Perforated – holes greater than 25% of the brick volume · Keyed – indentations in at least one face and end to be used with rendering and plastering · Paving – brick intended to be in ground contact as a walkway or roadway · Thin – brick with normal height and length but thin width to be used as a veneer Specialized use bricks: · Chemically resistant – bricks made with resistance to chemicals · Acid brick – acid resistant bricks · Engineering – a type of hard, dense, brick used where strength, low water porosity or acid (flue gas) resistance are needed. Further classified as type A and type B based on their compressive strength · Accrington – a type of engineering brick from England · Fire or refractory – highly heat-resistant bricks · Clinker – a vitrified brick · Ceramic glazed – fire bricks with a decorative glazing Bricks named for place of origin: · Cream City brick – a light yellow brick made in Milwaukee, Wisconsin · Dutch – a hard light coloured brick originally from the Netherlands · Fareham red brick – a type of construction brick · London stock – type of handmade brick which was used for the majority of building work in London and South East England until the growth in the use of machine-made bricks · Nanak Shahi bricks – a type of decorative brick in India · Roman – a long, flat brick typically used by the Romans · Staffordshire blue brick – a type of construction brick from England Methods of manufacture Mudbrick

Fired brick

Normally, bricks contain the following ingredients 1. Silica (sand) – 50% to 60% by weight 2. Alumina (clay) – 20% to 30% by weight 3. Lime – 2 to 5% by weight 4. Iron oxide – ≤ 7% by weight 5. Magnesia – less than 1% by weight Shaping methods

· Molded bricks – These bricks start with raw clay, preferably in a mix with 25–30% sand to reduce shrinkage. The clay is first ground and mixed with water to the desired consistency. The clay is then pressed into steel moulds with a hydraulic press. The shaped clay is then fired ("burned") at 900–1000 °C to achieve strength. · Dry-pressed bricks – The dry-press method is similar to the soft-mud moulded method, but starts with a much thicker clay mix, so it forms more accurate, sharper-edged bricks. The greater force in pressing and the longer burn make this method more expensive. · Extruded bricks – For extruded bricks the clay is mixed with 10–15% water (stiff extrusion) or 20–25% water (soft extrusion) in a pugmill. This mixture is forced through a die to create a long cable of material of the desired width and depth. This mass is then cut into bricks of the desired length by a wall of wires. Most structural bricks are made by this method as it produces hard, dense bricks, and suitable dies can produce perforations as well. The introduction of such holes reduces the volume of clay needed, and hence the cost. Hollow bricks are lighter and easier to handle, and have different thermal properties from solid bricks. The cut bricks are hardened by drying for 20 to 40 hours at 50 to 150 °C before being fired. The heat for drying is often waste heat from the kiln. Kilns

The other major kiln type is the Bull's Trench Kiln (BTK), based on a design developed by British engineer W. Bull in the late 19th century. An oval or circular trench is dug, 6–9 metres wide, 2-2.5 metres deep, and 100–150 metres in circumference. A tall exhaust chimney is constructed in the centre. Half or more of the trench is filled with "green" (unfired) bricks which are stacked in an open lattice pattern to allow airflow. The lattice is capped with a roofing layer of finished brick. In operation, new green bricks, along with roofing bricks, are stacked at one end of the brick pile; cooled finished bricks are removed from the other end for transport to their destinations. In the middle, the brick workers create a firing zone by dropping fuel (coal, wood, oil, debris, and so on) through access holes in the roof above the trench. The advantage of the BTK design is a much greater energy efficiency compared with clamp or scove kilns. Sheet metal or boards are used to route the airflow through the brick lattice so that fresh air flows first through the recently burned bricks, heating the air, then through the active burning zone. The air continues through the green brick zone (pre-heating and drying the bricks), and finally out the chimney, where the rising gases create suction that pulls air through the system. The reuse of heated air yields savings in fuel cost. As with the rail process, the BTK process is continuous. A half-dozen labourers working around the clock can fire approximately 15,000–25,000 bricks a day. Unlike the rail process, in the BTK process the bricks do not move. Instead, the locations at which the bricks are loaded, fired, and unloaded gradually rotate through the trench. Influences on colour

An impervious and ornamental surface may be laid on brick either by salt glazing, in which salt is added during the burning process, or by the use of a slip, which is a glaze material into which the bricks are dipped. Subsequent reheating in the kiln fuses the slip into a glazed surface integral with the brick base. Chemically set bricks Chemically set bricks are not fired but may have the curing process accelerated by the application of heat and pressure in an autoclave. Calcium-silicate bricks

Concrete bricks

Concrete bricks are available in many colours and as an engineering brick made with sulfate-resisting Portland cement or equivalent. When made with adequate amount of cement they are suitable for harsh environments such as wet conditions and retaining walls. They are made to standards BS 6073, EN 771-3. Concrete bricks expand and contract more than clay or sandlime bricks so they need movement joints every 5 to 6 metres, but are similar to other bricks of similar density in thermal and sound resistance and fire resistance. Compressed earth blocks Compressed earth blocks are made mostly from slightly moistened local soils compressed with a mechanical hydraulic press or manual lever press. A small amount of a cement binder may be added, resulting in a stabilised compressed earth block Use

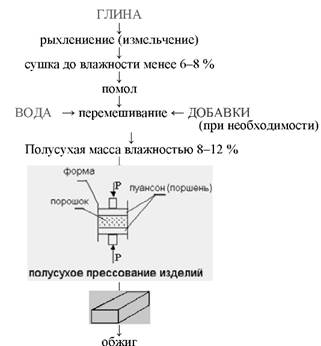

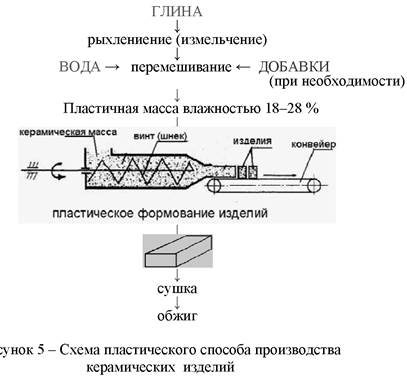

In the United States, bricks have been used for both buildings and pavements. Examples of brick use in buildings can be seen in colonial era buildings and other notable structures around the country. Bricks have been used in pavements especially during the late 19th century and early 20th century. The introduction of asphalt and concrete reduced the use of brick pavements, but it is used as a method of traffic calming or as a decorative surface in pedestrian precincts. For example, in the early 1900s, most of the streets in the city of Grand Rapids, Michigan, were paved with bricks. Today, there are only about 20 blocks of brick-paved streets remaining (totalling less than 0.5 percent of all the streets in the city limits). Much like in Grand Rapids, municipalities across the United States began replacing brick streets with inexpensive asphalt concrete by the mid-20th century. Bricks in the metallurgy and glass industries are often used for lining furnaces, in particular refractory bricks such as silica, magnesia, chamotte and neutral (chromomagnesite) refractory bricks. This type of brick must have good thermal shock resistance, refractoriness under load, high melting point, and satisfactory porosity. There is a large refractory brick industry, especially in the United Kingdom, Japan, the United States, Belgium and the Netherlands. In Northwest Europe, bricks have been used in construction for centuries. Until recently, almost all houses were built almost entirely from bricks. Although many houses are now built using a mixture of concrete blocks and other materials, many houses are skinned with a layer of bricks on the outside for aesthetic appeal. Engineering bricks are used where strength, low water porosity or acid (flue gas) resistance are needed. In the UK a redbrick university is one founded and built in the Victorian era. The term is used to refer to such institutions collectively to distinguish them from the older Oxbridge institutions, the post-war 'plate glass' universities, and the "new" universities of the 1990s. Colombian architect Rogelio Salmona was noted for his extensive use of red bricks in his buildings and for using natural shapes like spirals, radial geometry and curves in his designs.[ Most buildings in Colombia are made of brick, given the abundance of clay in equatorial countries like this one. ДРЕВЕСИНА В строительстве в основном используют древесину хвойных пород - сосну, ель, лиственницу, пихту, кедр. Из лиственных пород используют преимущественно дуб, ясень, бук, березу, осину. In construction, they mainly use coniferous wood - pine, spruce, larch, fir, cedar. Of the deciduous species, oak, ash, beech, birch, and aspen are used predominantly. Положительные свойства древесины. Как строительный материал, древесина обладает достаточно высокой прочностью, легкостью, низкой теплопроводностью, легкостью обработки и простотой скрепления деталей друг с другом. В благоприятных условиях эксплуатации деревянные постройки и строительные детали долговечны, сохраняются десятки и сотни лет. Positive properties of wood. As a building material, wood has a sufficiently high strength, lightness, low heat conductivity, ease of processing and ease of fastening parts to each other. In favorable operating conditions, wooden buildings and construction details are durable, tens and hundreds of years are preserved. С целью устранения в процессе эксплуатации изделий из древесины коробления, гниения она должна быть предварительно высушена. Кроме того, для предупреждения загнивания древесина должна быть изолирована от грунта, кирпича, бетона и других каменных материалов гидроизоляционными материалами (битумом, рубероидом, полиэтиленом и др.). Наиболее радикальным средством защиты древесины от гниения, поражения грибами и насекомыми является пропитка антисептиками - специальными химическими веществами. In order to eliminate during the operation of wood products warping, rotting, it must be pre-dried. In addition, to prevent decay, the wood must be isolated from soil, brick, concrete and other stone materials with waterproofing materials (bitumen, roofing material, polyethylene, etc.). The most radical means of protecting wood from decay, damage by fungi and insects is impregnation with antiseptics - special chemicals. КЕРАМИЧЕСКИЕ МАТЕРИАЛЫ Керамическими называют искусственные каменные материалы, получаемые из тонкодисперсного минерального сырья, преимущественно глинистого, путем формования, сушки и обжига. Ceramic are called artificial stone materials obtained from finely dispersed mineral raw materials, mainly clay, by molding, drying and firing. Глины - это породы, имеющие в своём составе мельчайшие частицы глинистых минералов с размерами менее 5 мкм - каолинит, монтмориллонит, гидрослюды, - обеспечивающие глинам в увлажнённом состоянии пластичность, некоторую прочность после сушки и камнеподобные свойства после обжига (прочность, водостойкость, морозостойкость). Clays are rocks containing the smallest particles of clay minerals with sizes less than 5 microns - kaolinite, montmorillonite, hydromica, which provide clay in a moistened state, plasticity, some strength after drying and stone-like properties after firing (strength, water resistance, frost resistance). В зависимости от способа приготовления керамической массы и формования изделий различают полусухой, пластический и литьевой способы производства керамических изделий. Depending on the method of preparation of the ceramic mass and the molding of products, there are semi-dry, plastic and injection methods for the production of ceramic products. Полусухой способ (рисунок 4) - получают полусухой порошок с влажностью 8-12 %, из которого методом одно- или двухстороннего прессования получают изделия, которые можно сразу обжигать. Semi-dry method (Figure 4) - a semi-dry powder with a moisture content of 8-12% is obtained, from which products can be burned immediately by single or double-sided pressing. punch, piston – пуансон, поршень Loosening, shredding – рыхление, измельчение, grinding - помол moisture content - влажность powder - порошок Пластический способ (рисунок 5) - получают пластичную массу с влажностью 18-28 %, из которой методом выдавливания и последующей разрезки получают изделия, которые сушат и обжигают. Plastic method (Figure 5) - a plastic mass with a moisture content of 18-28% is obtained, from which products are dried and calcined by extrusion and subsequent cutting. Loosening, shredding – рыхление, измельчение, molding – формование screw – шнек conveyor belt – ленточный конвеер drying - сушка firing - обжиг Сушат керамические изделия чаще всего на вагонетках или конвейерах в туннельных сушилках, а обжигают - в туннельных печах. Температура обжига изделий зависит от количества и типа плавней, содержащихся в глинах, или специально добавляемых при производстве изделий и может быть от 900 до 1380°С. С целью улучшения поверхностей и повышения долговечности керамические изделия могут покрываться глазурью Ceramic products are most often dried on trolleys or conveyors in tunnel dryers, and burned in tunnel kilns. The firing temperature of products depends on the amount and type of fluffs contained in clays, or specially added in the manufacture of products and can be from 900 to 1380 ° C. С целью улучшения поверхностей и повышения долговечности керамические изделия могут покрываться глазурью. In order to improve surfaces and increase durability, ceramic products may be coated with glaze. Литьевой способ - глину и измельчённые добавки смешивают с 35-45 % воды и получают текучую массу (шликер), которую разливают в пористые (гипсовые) формы или на пористые (керамические) поддоны. Injection method - clay and crushed additives are mixed with 35-45% of water and a fluid mass (slip) is obtained, which is poured into porous (gypsum) forms or onto porous (ceramic) pallets. Ceramic wall materials Керамический кирпич К керамическим материалам для стен относятся кирпичи и камни. Их получают из легкоплавких глин, содержащих повышенное количество гидроксида железа, являющегося плавнем. Он окрашивает глину в жёлто-коричневые тона, а готовые изделия в красные вследствие его разложения при обжиге и превращения в оксид железа. Кирпич и камни формуют в основном пластическим способом, реже - полусухим, затем сушат и обжигают при 900-1000°С. Кирпич полусухого прессования в некоторых случаях уступает кирпичу пластического формования по прочности при изгибе и морозостойкости. Ceramic materials for walls include bricks and stones. They are obtained from fusible clays containing an increased amount of iron hydroxide, which is smooth. It stains clay in yellow-brown tones, and finished products in red due to its decomposition during firing and conversion to iron oxide. Brick and stones are molded mainly in a plastic way, less often semi-dry, then dried and fired at 900-1000 ° С. Semi-dry pressing bricks in some cases are inferior to plastic molding bricks in terms of bending strength and frost resistance. По размерам чаще всего изготавливают следующие изделия: 250 х 120 х 65 - кирпич одинарный; 250 x 120 x 65 - single brick; 250 х 120 х 88 - кирпич утолщенный; 250 x 120 x 88 - thickened brick; 250 х 120 х 140 - камень (двойной кирпич). 250 x 120 x 140 - stone (double brick). Реже изготавливают другие изделия - кирпич и камни модульных размеров, крупноформатные камни с размерами до 510 х 250 х 219 мм. Other products are less commonly made - bricks and stones of modular sizes, large-format stones with sizes up to 510 x 250 x 219 mm. Кирпичи и камни с вышеуказанными размерами по прочности делят на марки 100, 125, 150, 175, 200, 250, 300 (прочность при сжатии 10-30 МПа). Крупноформатные камни имеют другие марки по прочности. Bricks and stones with the above dimensions in strength are divided into grades 100, 125, 150, 175, 200, 250, 300 (compressive strength 10-30 MPa). Large-format stones have other brands in strength. По морозостойкости в водонасыщенном состоянии изделия делят на марки F25, F35, F50 F75, F100 (25-100 циклов). According to frost resistance in a water-saturated state, the products are divided into brands F25, F35, F50 F75, F100 (25-100 cycles). Керамические кирпичи и камни делят на лицевые, применяемые для кладки лицевых поверхностей, и рядовые, применяемые для внутренних стен, перегородок и т.д. К лицевым изделиям применяют более высокие требования по внешнему виду, прочности, морозостойкости, отклонениям от размеров. Ceramic bricks and stones are divided into face bricks, used for masonry of front surfaces, and ordinary, used for internal walls, partitions, etc. Facial products are subject to higher requirements in terms of appearance, strength, frost resistance, and dimensional deviations. Применение. Керамический кирпич и камни применяют во всех частях зданий для кладки каменных и армокаменных конструкций, в том числе сырых и влажных помещений, подвалов, цоколей, а также дымовых труб. Application. Ceramic bricks and stones are used in all parts of buildings for masonry of stone and reinforced stone structures, including damp and wet rooms, basements, socles, and chimneys. Ceramic tiles Керамическая плитка бывает трёх видов: для внутренних стен, для фасадов, для пола. Отличается большим разнообразием по форме и размерам, свойствам. Основным сырьём для плиток служит глина. Широко применяют и добавки: плавни (полевой шпат и др.), отощающие (снижают пластичность и усадку глины - кварцевый песок, обожженная глина и др.). В настоящее время керамические плитки формуют преимущественно полусухим прессованием. После формования плитки сушат, потом обжигают при температуре от 950 до 1200°С для разных плиток. При производстве глазурованных плиток после сушки или после обжига наносят глазурь, затем обжигают. Ceramic tiles come in three forms: for interior walls, for facades, for floors. Differs in a wide variety in the form and sizes, properties. The main raw material for tiles is clay. Additives are widely used: melt (feldspar, etc.), thinning (reduce plasticity and shrinkage of clay - quartz sand, calcined clay, etc.). Currently, ceramic tiles are formed mainly by semi-dry pressing. After molding, the tiles are dried, then fired at a temperature of from 950 to 1200 ° C for different tiles. In the production of glazed tiles after drying or after firing, glaze is applied, then fired. Porcelain tile Керамогранит - современный облицовочный материал, получаемый более тщательной подготовкой исходных материалов - высококачественной глины, отощающих добавок и плавней, прессуемый при более высоких удельных давлениях - 40-50 МПа и обжигаемый при более высоких температурах - 1200-1300°С. В результате получается керамический материал, сравнимый по свойствам с природным гранитом по прочности, водопоглощению, морозостойкости. Керамогранит применяют для облицовки фасадов, полов, для мощения дорожек. Porcelain tile is a modern facing material obtained by a more thorough preparation of the starting materials - high-quality clay, thinning additives and fluffs, pressed at higher specific pressures - 40-50 MPa and fired at higher temperatures - 1200-1300 ° С. The result is a ceramic material comparable in properties to natural granite in strength, water absorption, and frost resistance. Porcelain tile is used for facing facades, floors, for paving paths. Sanitary-technical ceramics Санитарно-техническая керамика включает более 30 наименований изделий, предназначенных для санитарного благоустройства зданий - раковины, унитазы, биде и др. Sanitary-technical ceramics includes more than 30 items of products intended for sanitary improvement of buildings - sinks, toilets, bidets, etc. Санитарно-технические изделия могут быть фаянсовыми или полуфарфоровыми, или фарфоровыми, отличающимися разным соотношением сырьевых материалов, основным компонентом которых являются беложгущиеся огнеупорные глины 45-50%. В качестве плавней используют полевой шпат в количестве 2-5% у фаянса, 7-12% у полуфарфора и 18-22% у фарфора. Остальное до 100% - отощающие добавки, чаще всего кварц. Sanitary products can be earthenware or semi-porcelain, or porcelain, differing in different ratios of raw materials, the main component of which are white-burning refractory clays of 45-50%. Feldspar in the amount of 2-5% in earthenware, 7-12% in semi-porcelain and 18-22% in porcelain are used as fluxes. The rest up to 100% are exhausting additives, most often quartz. Производство. Размалывают в мельницах все компоненты, смешивают их друг с другом и с водой (35-45 % воды от массы сухих компонентов), заливают смесь в гипсовые формы, извлекают изделия из форм, сушат, наносят глазурь и обжигают: фаянс при температуре до 1280°С, полуфарфор - до 1350°С, фарфор - до 1380°С. Production. Grind all the components in the mills, mix them with each other and with water (35-45% of the water by weight of the dry components), pour the mixture into gypsum molds, remove the products from the molds, dry, apply glaze and burn: faience at temperatures up to 1280 ° C, semi-porcelain - up to 1350 ° С, porcelain - up to 1380 ° С. Expanded clay Керамзит - пористый материал в виде округлых гранул, получаемый из глины, путем ее вспучивания во время обжига. Из глины, воды и добавок (мазут, уголь и др.) готовят пластичную массу, которую выдавливают из пресса через решетку с отверстиями. Полученные гранулы сушат и обжигают в цилиндрической вращающейся слегка наклонённой печи (рисунок 7). При температуре 1200-1250°С в печи гранулы расплавляются и вспучиваются парами воды и газами, выделяющимися при сгорании добавок. После охлаждения керамзит рассеивают на фракции: 0-5 мм - керамзитовый песок; 5-40 мм - керамзитовый гравий. Керамзит используют как заполнитель в легких бетонах со средней плотностью 800-1200 кг/м3, как теплоизоляционную засыпку для повышения теплоизоляции полов, перекрытий, стен. Expanded clay is a porous material in the form of rounded granules obtained from clay by swelling it during firing. From clay, water and additives (fuel oil, coal, etc.) a plastic mass is prepared, which is squeezed out of the press through a grid with holes. The obtained granules are dried and fired in a cylindrical rotating slightly tilted furnace (Figure 7). At a temperature of 1200-1250 ° C in the furnace, the granules melt and swell with water vapor and gases released during the combustion of additives. After cooling, expanded clay is dispersed into fractions: 0-5 mm - expanded clay sand; 5-40 mm - expanded clay gravel. Expanded clay is used as a filler in lightweight concrete with an average density of 800-1200 kg / m3, as a heat-insulating backfill to increase the thermal insulation of floors, ceilings, walls. WOOD MATERIALS Wood is a porous and fibrous structural tissue found in the stems and roots of trees and other woody plants. It is an organic material, a natural composite of cellulose fibers that are strong in tension and embedded in a matrix of lignin that resists compression. Wood is sometimes defined as only the secondary xylem in the stems of trees, or it is defined more broadly to include the same type of tissue elsewhere such as in the roots of trees or shrubs. In a living tree it performs a support function, enabling woody plants to grow large or to stand up by themselves. It also conveys water and nutrients between the leaves, other growing tissues, and the roots. Wood may also refer to other plant materials with comparable properties, and to material engineered from wood, or wood chips or fiber. Wood has been used for thousands of years for fuel, as a construction material, for making tools and weapons, furniture and paper, and as a feedstock for the production of purified cellulose and its derivatives, such as cellophane and cellulose acetate. In 2005, the growing stock of forests worldwide was about 434 billion cubic meters, 47% of which was commercial. As an abundant, carbon-neutral renewable resource, woody materials have been of intense interest as a source of renewable energy. In 1991 approximately 3.5 billion cubic meters of wood were harvested. Dominant uses were for furniture and building construction. HEARTWOOD Heartwood (or duramen) is wood that as a result of a naturally occurring chemical transformation has become more resistant to decay. Heartwood formation is a genetically programmed process that occurs spontaneously. Some uncertainty exists as to whether the wood dies during heartwood formation, as it can still chemically react to decay organisms, but only once. Heartwood is often visually distinct from the living sapwood, and can be distinguished in a cross-section where the boundary will tend to follow the growth rings. For example, it is sometimes much darker. However, other processes such as decay or insect invasion can also discolor wood, even in woody plants that do not form heartwood, which may lead to confusion. Sapwood (or alburnum) is the younger, outermost wood; in the growing tree it is living wood, and its principal functions are to conduct water from the roots to the leaves and to store up and give back according to the season the reserves prepared in the leaves. However, by the time they become competent to conduct water, all xylem tracheids and vessels have lost their cytoplasm and the cells are therefore functionally dead. All wood in a tree is first formed as sapwood. The more leaves a tree bears and the more vigorous its growth, the larger the volume of sapwood required. Hence trees making rapid growth in the open have thicker sapwood for their size than trees of the same species growing in dense forests. Sometimes trees (of species that do form heartwood) grown in the open may become of considerable size, 30 cm (12 in) or more in diameter, before any heartwood begins to form, for example, in second-growth hickory, or open-grown pines. The term heartwood derives solely from its position and not from any vital importance to the tree. This is evidenced by the fact that a tree can thrive with its heart completely decayed. Some species begin to form heartwood very early in life, so having only a thin layer of live sapwood, while in others the change comes slowly. Thin sapwood is characteristic of such species as chestnut, black locust, mulberry, osage-orange, and sassafras, while in maple, ash, hickory, hackberry, beech, and pine, thick sapwood is the rule. Others never form heartwood. No definite relation exists between the annual rings of growth and the amount of sapwood. Within the same species the cross-sectional area of the sapwood is very roughly proportional to the size of the crown of the tree. If the rings are narrow, more of them are required than where they are wide. As the tree gets larger, the sapwood must necessarily become thinner or increase materially in volume. Sapwood is relatively thicker in the upper portion of the trunk of a tree than near the base, because the age and the diameter of the upper sections are less. When a tree is very young it is covered with limbs almost, if not entirely, to the ground, but as it grows older some or all of them will eventually die and are either broken off or fall off. Subsequent growth of wood may completely conceal the stubs which will however remain as knots. No matter how smooth and clear a log is on the outside, it is more or less knotty near the middle. Consequently, the sapwood of an old tree, and particularly of a forest-grown tree, will be freer from knots than the inner heartwood. Since in most uses of wood, knots are defects that weaken the timber and interfere with its ease of working and other properties, it follows that a given piece of sapwood, because of its position in the tree, may well be stronger than a piece of heartwood from the same tree. It is remarkable that the inner heartwood of old trees remains as sound as it usually does, since in many cases it is hundreds, and in a few instances thousands, of years old. Every broken limb or root, or deep wound from fire, insects, or falling timber, may afford an entrance for decay, which, once started, may penetrate to all parts of the trunk. The larvae of many insects bore into the trees and their tunnels remain indefinitely as sources of weakness. Whatever advantages, however, that sapwood may have in this connection are due solely to its relative age and position. If a tree grows all its life in the open and the conditions of soil and site remain unchanged, it will make its most rapid growth in youth, and gradually decline. The annual rings of growth are for many years quite wide, but later they become narrower and narrower. Since each succeeding ring is laid down on the outside of the wood previously formed, it follows that unless a tr

|

||

|

Последнее изменение этой страницы: 2021-07-19; просмотров: 178; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 3.143.228.40 (0.006 с.) |

Unfired bricks, also known as mudbricks, are made from a wet, clay-containing soil mixed with straw or similar binders. They are air-dried until ready for use.

Unfired bricks, also known as mudbricks, are made from a wet, clay-containing soil mixed with straw or similar binders. They are air-dried until ready for use. Fired bricks are burned in a kiln which makes them durable. Modern, fired, clay bricks are formed in one of three processes – soft mud, dry press, or extruded. Depending on the country, either the extruded or soft mud method is the most common, since they are the most economical.

Fired bricks are burned in a kiln which makes them durable. Modern, fired, clay bricks are formed in one of three processes – soft mud, dry press, or extruded. Depending on the country, either the extruded or soft mud method is the most common, since they are the most economical. Three main methods are used for shaping the raw materials into bricks to be fired:

Three main methods are used for shaping the raw materials into bricks to be fired: In many modern brickworks, bricks are usually fired in a continuously fired tunnel kiln, in which the bricks are fired as they move slowly through the kiln on conveyors, rails, or kiln cars, which achieves a more consistent brick product. The bricks often have lime, ash, and organic matter added, which accelerates the burning process.

In many modern brickworks, bricks are usually fired in a continuously fired tunnel kiln, in which the bricks are fired as they move slowly through the kiln on conveyors, rails, or kiln cars, which achieves a more consistent brick product. The bricks often have lime, ash, and organic matter added, which accelerates the burning process. The fired colour of tired clay bricks is influenced by the chemical and mineral content of the raw materials, the firing temperature, and the atmosphere in the kiln. For example, pink bricks are the result of a high iron content, white or yellow bricks have a higher lime content. Most bricks burn to various red hues; as the temperature is increased the colour moves through dark red, purple, and then to brown or grey at around 1,300 °C (2,372 °F). The names of bricks may reflect their origin and colour, such as London stock brick and Cambridgeshire White. Brick tinting may be performed to change the colour of bricks to blend-in areas of brickwork with the surrounding masonry.

The fired colour of tired clay bricks is influenced by the chemical and mineral content of the raw materials, the firing temperature, and the atmosphere in the kiln. For example, pink bricks are the result of a high iron content, white or yellow bricks have a higher lime content. Most bricks burn to various red hues; as the temperature is increased the colour moves through dark red, purple, and then to brown or grey at around 1,300 °C (2,372 °F). The names of bricks may reflect their origin and colour, such as London stock brick and Cambridgeshire White. Brick tinting may be performed to change the colour of bricks to blend-in areas of brickwork with the surrounding masonry. Calcium-silicate bricks are also called sandlime or flintlime bricks, depending on their ingredients. Rather than being made with clay they are made with lime binding the silicate material. The raw materials for calcium-silicate bricks include lime mixed in a proportion of about 1 to 10 with sand, quartz, crushed flint, or crushed siliceous rock together with mineral colourants. The materials are mixed and left until the lime is completely hydrated; the mixture is then pressed into moulds and cured in an autoclave for three to fourteen hours to speed the chemical hardening.[17] The finished bricks are very accurate and uniform, although the sharp arrises need careful handling to avoid damage to brick and bricklayer. The bricks can be made in a variety of colours; white, black, buff, and grey-blues are common, and pastel shades can be achieved. This type of brick is common in Sweden, especially in houses built or renovated in the 1970s. In India these are known as fly ash bricks, manufactured using the FaL-G (fly ash, lime, and gypsum) process. Calcium-silicate bricks are also manufactured in Canada and the United States, and meet the criteria set forth in ASTM C73 – 10 Standard Specification for Calcium Silicate Brick (Sand-Lime Brick).

Calcium-silicate bricks are also called sandlime or flintlime bricks, depending on their ingredients. Rather than being made with clay they are made with lime binding the silicate material. The raw materials for calcium-silicate bricks include lime mixed in a proportion of about 1 to 10 with sand, quartz, crushed flint, or crushed siliceous rock together with mineral colourants. The materials are mixed and left until the lime is completely hydrated; the mixture is then pressed into moulds and cured in an autoclave for three to fourteen hours to speed the chemical hardening.[17] The finished bricks are very accurate and uniform, although the sharp arrises need careful handling to avoid damage to brick and bricklayer. The bricks can be made in a variety of colours; white, black, buff, and grey-blues are common, and pastel shades can be achieved. This type of brick is common in Sweden, especially in houses built or renovated in the 1970s. In India these are known as fly ash bricks, manufactured using the FaL-G (fly ash, lime, and gypsum) process. Calcium-silicate bricks are also manufactured in Canada and the United States, and meet the criteria set forth in ASTM C73 – 10 Standard Specification for Calcium Silicate Brick (Sand-Lime Brick). Bricks formed from concrete are usually termed as blocks, and are typically pale grey. They are made from a dry, small aggregate concrete which is formed in steel moulds by vibration and compaction in either an "egglayer" or static machine. The finished blocks are cured, rather than fired, using low-pressure steam. Concrete blocks are manufactured in a much wider range of shapes and sizes than clay bricks and are also available with a wider range of face treatments – a number of which simulate the appearance of clay bricks.

Bricks formed from concrete are usually termed as blocks, and are typically pale grey. They are made from a dry, small aggregate concrete which is formed in steel moulds by vibration and compaction in either an "egglayer" or static machine. The finished blocks are cured, rather than fired, using low-pressure steam. Concrete blocks are manufactured in a much wider range of shapes and sizes than clay bricks and are also available with a wider range of face treatments – a number of which simulate the appearance of clay bricks.