Заглавная страница Избранные статьи Случайная статья Познавательные статьи Новые добавления Обратная связь КАТЕГОРИИ: ТОП 10 на сайте Приготовление дезинфицирующих растворов различной концентрацииТехника нижней прямой подачи мяча. Франко-прусская война (причины и последствия) Организация работы процедурного кабинета Смысловое и механическое запоминание, их место и роль в усвоении знаний Коммуникативные барьеры и пути их преодоления Обработка изделий медицинского назначения многократного применения Образцы текста публицистического стиля Четыре типа изменения баланса Задачи с ответами для Всероссийской олимпиады по праву

Мы поможем в написании ваших работ! ЗНАЕТЕ ЛИ ВЫ?

Влияние общества на человека

Приготовление дезинфицирующих растворов различной концентрации Практические работы по географии для 6 класса Организация работы процедурного кабинета Изменения в неживой природе осенью Уборка процедурного кабинета Сольфеджио. Все правила по сольфеджио Балочные системы. Определение реакций опор и моментов защемления |

Ministry of Education and Science of UkraineСтр 1 из 4Следующая ⇒

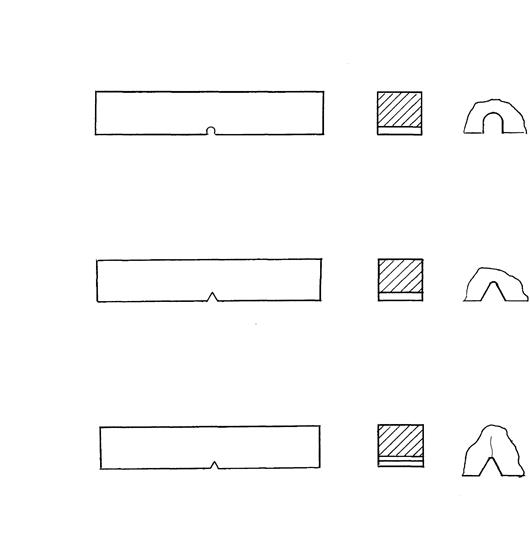

Choice of material and specimens type for pendulum-type impact machine testing, determination of impact toughness The bar reinforcement for reinforced concrete constructions is made from the hot-rolled and heat-strengthened metal of a certain strength level and proper steel grades. In the given the course paper materials for investigation are reinforcement bars of А400 class (steel 25Г2С in hot-rolled state), А600 class (steel 80С, 20ХГ2Т in hot-rolled state) and Ат600С class (25Г2С in heat-strengthened state after rolled heating and furnace heating) of 18mm diameter. The investigated material should be chosen in accordance with the student’s credit book in Appendix 2/ In practice, steel toughness is characterized by the impact bending tests results. The impact toughness is a work spent on deformation of notched specimen impact bending failure of notched specimen in result of its testing on pendulum-type impact machine. Shape and sizes of impact specimens (fig. 3.1), requirements to the test machines, order of testing at normal, low and high temperatures and analysis of obtained results are regulated by GOST–9454–78.

Fig. 3.1. Specimens for the impact bending test. a – U-notched specimen, «Menazhe» Type I; b – V-notched specimen, Type IV; c – T-notched specimen, fatigue crack.

Impact toughness can be found by the formula:

where F is the cross-section area in the notched place before the test, сm2. The values of impact toughness The specimen of type Ι is used as the basic one, so called «Menazhe» specimen. The GOST specifies the obligatory conducting of parallel tests on the specimen of type Ι at determination of impact toughness on the specimens of type II, III, IV. KCV (type IV)

Appendix 3 Test temperature: +100°С

Test temperature: + 60°С

Test temperature: + 20°С

Test temperature: 0°С

Test temperature: - 20°С

Test temperature: - 40°С

Test temperature: - 60°С

Test temperature: - 80°С

Test temperature: – 100°С

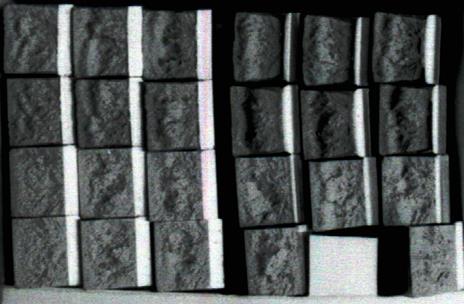

Appendix 4 Steel 80С, hot-rolled

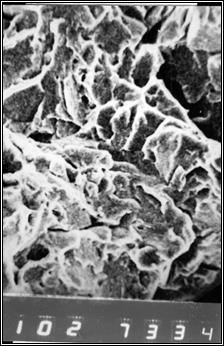

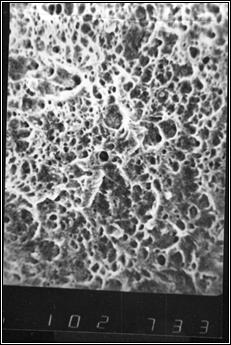

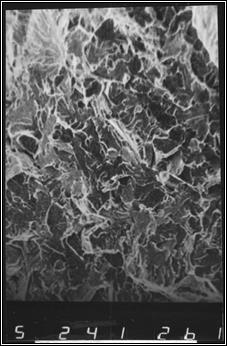

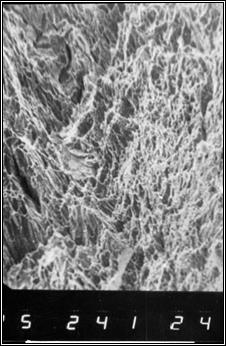

t=+20°C, х240 t=+20°C, х240

t=+20°C, х1000 t=+20°C, х1000

Steel 20ХГ2Т, hot-rolled

t=+20°C, х240 t=+20°C, х240

t=+20°C, х1200 t=+20°C, х1000

Steel 20ХГ2Т, hot-rolled

t=+20°C, х1000 t=-20°C, х240

t=-20°C, х1000 t=-60°C, х240

Steel 20ХГ2Т, hot-rolled

t=-60°C, х240 t=-60°C, х1000

t=-60°C, х1000 t=-60°C, х1000

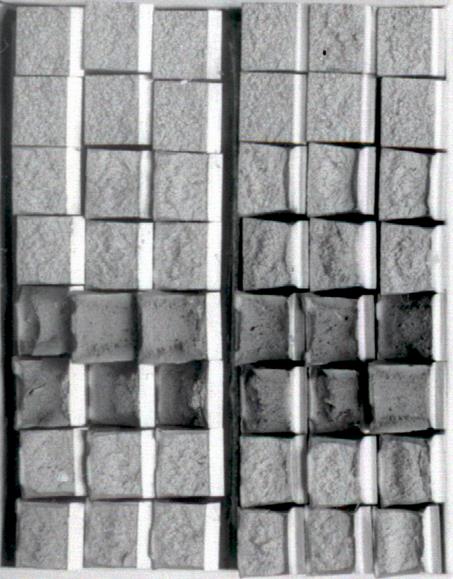

Steel 25Г2C, hot-rolled

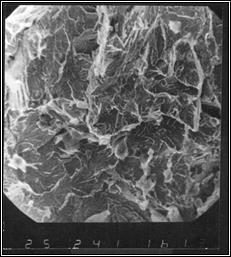

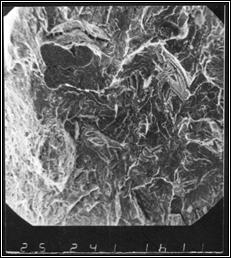

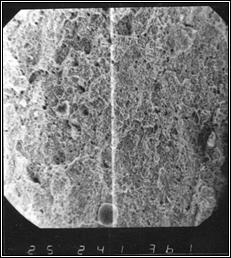

t=+20°C, х240 t=+20°C, х240

t=+20°C, х1000 t=+20°C, х1000

Steel 25Г2C, hot-rolled

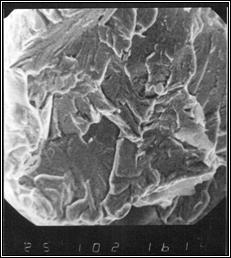

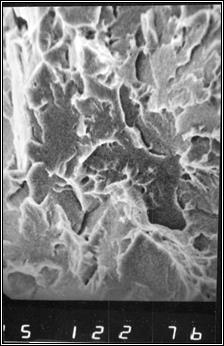

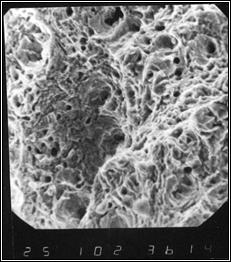

t=-20°C, х240 t=-20°C, х240

t=-20°C, х1000 t=-20°C, х1000

Steel 25Г2C, hot-rolled

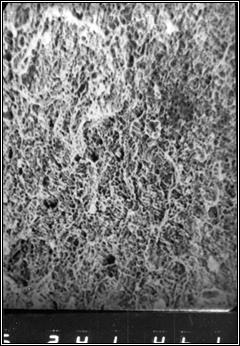

t=-60°C, х240 t=-60°C, х1000

t=-60°C, х1000 t=-60°C, х1000

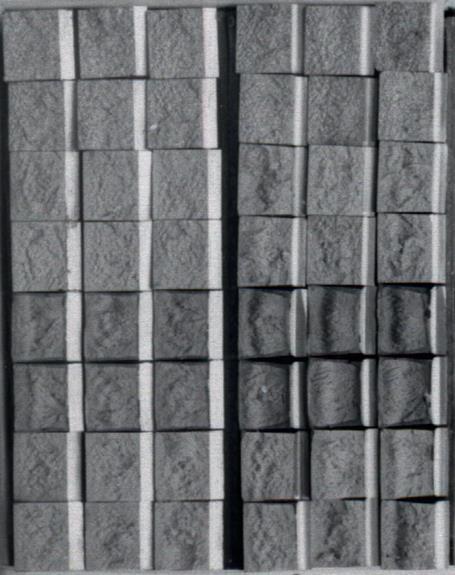

Steel of 25Г2C, TS furnace

t= +20°C, х240 t= +20°C, х240

t= +20°C, х1000 t= +20°C, х1000

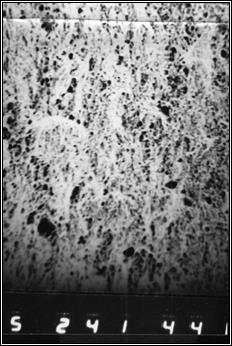

Steel 25Г2C, TS mill

t= +20°C, х240 t= +20°C, х240

t= +20°C, х1000 t= +20°C, х1000 Steel 25Г2C, TS mill

t= -20°C, х240 t= -20°C, х240

t= -20°C, х1000 t= -20°C, х1000

Steel 25Г2C, TS mill

t= -60°C, х240 t= -60°C, х240

t= -60°C, х1000 t= -60°C, х1000 Appendix 5 The explanatory note to the course paper is conventionally subdivided into: - introduction; - main part; - appendix. Introduction Introduction contains the following structural elements: - title page; - task for the course paper; - abstract; - contents; - list of conventional signs, symbols, contractions, terms. Title page A title page contains information that should be represented in the following sequence: a) information about the ministry, higher educational establishment, department; b) complete name of document. The division of words in the heading of title page is forbidden; c) signatures of supervisors, tutors and the student who executed this the course paper. The signatures of responsible persons are placed in the following order: to the left there should be the white space for the personal signatures. To the right of this white space the posts, surnames, names and patronymics should be pointed in appropriate lines. Below the personal signatures, there should be pointed the dates of signing in Arabic numerals in the following sequence: year, month, date. For example, December, 26, 2002 should be designed as: 2002.12.26. or 02.12.26., verbally-digital dates design is also possible: December, 26, 2002. d) year of explanatory note drawing up. Task of the course paper The supervisor formulates and gives the task. There should be the topic of the course paper, data values, list of questions that should be studied in the task. The timetable of work stages preparation can also be shown in the task. Abstract An abstract is intended for getting acquainted with a work. It is prepared in the official (Ukrainian) language. The abstract should be brief, informative and it should contain all necessary information that allows making the decision about the expedience of all explanatory note or report reading. The abstract is placed directly after a title page. It begins from a new page. The abstract should contain: - information about the note volume, quantity of illustrations, tables, appendixes, resources quantity in accordance with the list of references;

- text of the abstract; - list of keywords. The text of the abstract of the course paper should reflect the information given in the explanatory note in the following sequence: - object or research of the development; - purpose of the work; - research methods and equipment; - results and their novelty; - the main structural, technological and operational data and indices; - recommendations of the work data use; - economic efficiency; -summary. The abstract should contain one A4 page. The keywords are placed after the abstract text. The quantity of keywords should be from 5 to 15 words (word-combinations). The keywords should be written in capital letters in a line with commas. Contents The contents are placed right after the abstract. It begins from a new page. The contents include: introduction; all sections titles consequently listed, subsections titles; conclusions; list of references; appendixestitles and number of pages which the next material begins from.

Main part The main part contains the following structural elements: - Introduction; - Essence of explanatory note; - Conclusions; - Recommendations; - List of references. Introduction The introduction is placed on a separate page. The following items are included in the Introduction: - estimation of the modern state of problem, mentioning the solutions of a problem, problems of knowledge that exist in this field, leading scientists and specialists in this field; - world tendencies of pointed problems solutions; - actuality of this work and foundation for its implementation; - purpose of the work and its application field; - correlation with other works.

Essence of explanatory note The essence of the explanatory note is the exposition of reports about subject (object) of investigation or development. These reports are necessary and sufficient for opening of the essence of this work and its results. The material is broken up in sections. Sections can have subsections and paragraphs. If necessary paragraphs are divided into sub-paragraphs. If it is necessary to give complete proofs in the work (for example, mathematical – in the works that have no direct attitude to mathematics) or research details, they are placed in appendixes. Units of IS should be used in the explanatory note. If measuring is conducted in other units, its conversion in unit of IS is obligatory only in the case of the work main points expounding. In the text of explanatory note it is not allowed: - to use different scientific and technical terms for one conception. Also to use foreign words and terms at presence of equivalent words and terms in Russian or Ukrainian; - to use of words abbreviations, except those set by the orthographic rules, punctuation and proper state standards; - To apply mathematical signs without numbers (for example №, %, = and so on) Conclusions The summary is placed right after the expounding of the explanatory note essence beginning from a new page. Results estimation, possible fields of results application, economical and social meaning of the work should be brought up in the summary. The text of conclusions can be divided into paragraphs. List of references The list of resources which are referred in the main part of the explanatory note is cited at the end of the explanatory note text beginning from a new page. Bibliographic descriptions from the list of references are presented in the order according to which they are first mentioned in a text (number references). Bibliographic descriptions in the list of references are brought up in accordance with the real standards of library and edition business. Requirements tо structural elements presentation The following structural elements are obligatory: · title page, · abstract, · introduction, · essence of explanatory note, · conclusions. Title page, task and abstract parts are written in Ukrainian.

Common requirements The explanatory note depending on its features and contents should be prepared in the form of text, illustrations or tables of their contents. The explanatory note is designed on the sheets of А4 format (210´297 mm). The usage of sheets of АЗ format (297 х 420 mm) is assumed if it is necessary. The explanatory note is executed by handwriting or, with administration permission, in printing (with the help of computer) on one side of sheet. If handwritten the explanatory note should contain 30-35 lines on one page, if printed there must be not more than 40 lines on one page, providing the page is uniformly filled and letters are of 1.8 mm height. The explanatory note should be executed with taking the following sizes of indentions into account: left – no less than 30 mm, overhead and lower – no less than 20 mm, right – no less than 10 mm. It is necessary to follow uniform density, contrast and clearness of image in the whole note. All lines, letters, numbers and signs must be of one color (black, violet or dark blue) throughout the note. Separate words, formulas, signs that are brought up in the printed text should be black, the density of inscribed text should maximally approach to the density of basic image. Errors, slips of the pen and graphic inaccuracies are assumed to be corrected by rubbing out or painting out with white paint. Correction should be placed on the same space or between lines. Correction has to be of the same color as the note. Sections and subsections should have titles. Paragraphs and subparagraphs could have titles. Titles of structural elements of the explanatory note and titles of sections should be disposed in the middle of a line, printed in capital letters without a point at the end. Titles should not be underlined. The transfer of words in the title of section is not allowed. Indention has to be the same throughout the whole text of the explanatory note and equal to five signs. Distance between the title and the next or previous text is not less than two lines.

Explanatory note pagination Pages of the explanatory note should be numerated by Arabic numerals with continuous numbering through the whole text of the note. The number of a page is put in the top right corner of the page without a point at the end. The title page is included in general pagination of the explanatory note. The page number on the title page is not placed. Illustrations and tables which are placed on separate pages are included in general pagination of the explanatory note.

Illustrations Illustrations (drafts, pictures, graphs, charts, diagrams, photos) should be placed in the explanatory note right after the text where they are mentioned or on the next page. There should be references to all the illustrations. Points received while testing should be marked on the graphs that contain experimental curves. If a graph is graticulated, then arrows are not marked on coordinate axes. If a graph is not graticulated, then it should end with arrows. If axes are graduated, then it is necessary to specify units.

Tables As a rule, numerical material is designed in the form of tables. The table should be placed right after the text where it is mentioned for the first time or on next page. There have to be references to all the tables in the text of the explanatory note. Tables are numbered by Arabic numerals and serial numbering within the limits of a section. The table should have the title written in small letters (except for the first capital letter) and be disposed above a table. The title have to be brief and significant.

Resources 1. Гуляев А.П. Металловедение. – М: Металлургия, 1978. – 648 с. 2. Фридман Я.Б. Механические свойства металлов. 1, 2 т. – М.: Машиностроение, 1974. 3. Макклинток Ф., Аргон А. Деформация и разрушение материалов. – М.: "Мир", 1970. – 444 с. 4. Мак Лин Д. Механические свойства металлов. – М.: Металлургия, 1965. – 432 с. 5. Берштейн М.А., Займовський В.А. Механические свойства материалов. – М.: Металлургия, 1979. – 495 с. 6. Мак Лин Д. Механические свойства металлов. – М.: Металлургия, 1965. – 431 с. 7. Шапошников Н.А. Механические испытания металлов. – М.: Машгиз, 1951. – 384 с. 8. Авдеев Б.А. Испытательные машины и приборы. – М.: Машгиз, 1957. – 351 с. 9. Золотаревский В.С. Механические свойства металлов. – М.: Металлургия, 1983. – 431 с.

VOcabulary

Contents 1. introduction......................................................................... 3 2. STRUCTURE OF THE COURSE PAPER.................................. 5 3. contents of the course paper parts....................... 6 3.1. Introduction.............................................................................. 6 3.2. Main part.................................................................................. 6 3.2.1. Choice of material and specimens type for pendulum-type impact machine testing, determination of impact toughness.............................................. 6 3.2.2. Description and estimation of fracture type...................... 8 3.2.3. Estimation of influence of impact specimens notch radius on fracture character.................................................................................................. 12 3.2.4. Determination of cold brittleness temperature by means of serial dynamic bending tests........................................................................................... 14 Appendix 1 TASK........................................................................ 17 Appendix 2 impact toughness values after test of impact specimens................................................................................... 18 KCU (type Ι)............................................................................. 18 KCV (type IV)........................................................................... 18

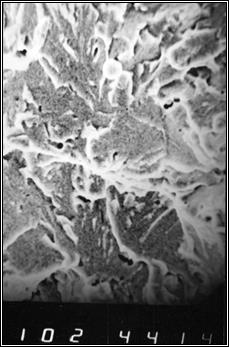

Appendix 3 macrophotographies of fractures... 19 Appendix 4 microphotographies of fractures.... 28 Appendix 5 design regulations of the course paper 39 Introduction.................................................................................. 39 Title page................................................................................... 39 Task of the course paper........................................................... 40 Abstract..................................................................................... 40 Contents.................................................................................... 41 List of conventional signs, symbols, contractions, terms………….41 Main part...................................................................................... 41 Introduction............................................................................... 42 Essence of the explanatory note................................................ 42 Conclusions............................................................................... 43 List of references....................................................................... 43 Requirements tо structural elements presentation..................... 43 Rules of explanatory note design Resources.................................................................................. 46 Vocabulary.............................................................................. 47

Ministry of Education and Science of Ukraine Prydniprovs’ka State Academy of Civil Engineering and Architecture

Materials Science and Materials Treatment Department

Methodical instructions for accomplishment of the course paper “Mechanical properties and structural strength of materials”

Dnipropetrovs’k – 2008 UDK 669.017: 620.17 Methodical instructions for accomplishment of the course paper in “Mechanical Properties and Structural Strength of Materials” in Applied Materials Science / Authors: Bolshakov V.I., Laukhin D.V., Tchaikovs’ky O.A., Tchaikovs’ka A.O., Beketov O.V., Bereza М.К., Kuksenko V.I., Ryazanova A.V. – Dnipropetrovs'k, PSACE&A, 2007. – 47 pages.

Methodical instructions for accomplishment of the course paper «Mechanical Properties and Structural Strength of Materials» are designed for students of «Applied Materials Science» specialty of internal and extra-mural forms of studies (6.090100, 7.090101). The main aims of methodical instructions are to consolidate knowledge acquired at the discipline study, to train ability to choose and to use correctly the estimation method of steel ductile properties, on the basis of which it is possible to find out the effect of different factors on liability to brittle fracture, to know the physical meaning of impact toughness and its constituents and to know the estimation criteria of ductile-brittle steel transition.

Authors: Doctor of Technical Sciences Bolshakov V.I., Ph.D. Laukhin D.V., Teacher of English Bereza M.K. Ph.D. Tchaikovs’ky O.A., Assistant Tchaikovs’ka A.O., Ph.D. Beketov A.V., Ph.D. student Kuksenko V.I., Student Ryazanova A.V.

Responsible for the edition: Bolshakov V.I. Doctor of Technical Science, professor. Reviewer: Kharchenko V.I., Ph.D., professor of Materials Science and Materials Treatment Department

Approved at the meeting of Materials Science and Materials Treatment Department Protocol №10 05.02.08 The Head of the Department professor V.I. Bolshakov Approved at the methodical council meeting of Prydneprovs’ka State Academy of Civil Engineering and Architecture Protocol № 4 (50) 25.03.2008 1. introduction Preparation of the course paper in discipline «Mechanical Properties and Structural Strength of Materials» for the students of «Applied Materials Science» specialty is intended: to consolidate knowledge acquired at the discipline study, to train ability to choose and to use correctly the evolution method of steel ductile properties, on the basis of which it is possible to find out the effect of different factors on liability to brittle fracture, to know the physical meaning of impact toughness and its constituents and to know the estimation criteria of ductile-brittle steel transition. The course paper is accomplished in accordance with the general theme «Impact toughness test of hot-rolled and heat-strengthened steel reinforcement». At tasks distribution a teacher determines the variant that directly formulates the theme of the course paper. Physical and mechanical properties of metals depend on the atomic-crystalline structure, micro- and macrostructures and on such factors as temperature and charts of the stressed state. Consequently, for preparation of the course paper it is necessary not only to be oriented in the studied discipline but also to be able to use knowledge in different branches of physics, resistance of materials, crystallography and metallography. Accomplishment of the course paper should be started with the diligent analysis of literary resources that are recommended in the given methodical instructions and those found as a result of bibliographic search on this topic. After the literature review, a student should know: - the main statements about toughness; - fracture types, visual estimation of fracture, effect of notch radius of impact specimens on fracture character; - serial curves of toughness characteristics; - determination of critical temperature - physical sense of fracture appearance transition temperature (FATT) ТК determined by serial curves.

The studied information is necessary for the solution of such problems as serial curves construction, critical temperatures determination, fracture types determination, comparative analysis of ductile properties of reinforced, hot-rolled and heat-strengthened steels prepared by different technologies. The course paper is designed on the sheets of paper of А4 format according to the USDC requirements for design of research reports taking into account instructions of the Appendix 5. A student should defend the designed work after correction by a teacher.

2. STRUCTURE OF THE COURSE PAPER According to the Appendix 5 the designed course paper should contain: 1. Title page. 2. Contents. 3. Abstract. 4. Introduction. 5. Main part. 5.1. Choice of material and type of specimens for pendulum-type impact testing machine (Appendix 1). 5.2. Construction of serial curves on the base of defined data of impact toughness for different materials (Appendix 2). 5.3. Determination of cold brittleness temperature for different materials on the base of dynamic bending tests. 5.4. Determination of influence of notch type of impact specimens on fracture character. 5.5. Macrofractographic analysis of specimens fractures for dynamic tests (Appendix 3). 5.6. Comparison of fractures of different steels at the same tests temperatures. 5.7. Determination of impact specimens test temperature influence on fracture character. 5.8. Microfractographic analysis of specimens fractures for dynamic tests (Appendix 4). 5.9. Determination of impact specimens test temperature influence on fracture character. - Conclusions. - Resources. - Appendixes. 3. contents of the course paper parts 3.1. Introduction In the introduction to the course paper it is necessary to sketch the role of problem of brittle fracture in result of difficult conditions of work of machines and buildings at the constant increase of working stresses, rise of dynamic loadings and decrease of working temperatures. It is necessary to formulate the task of the work. The introduction should be about 2 pages. 3.2. Main part

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Последнее изменение этой страницы: 2016-12-28; просмотров: 155; Нарушение авторского права страницы; Мы поможем в написании вашей работы! infopedia.su Все материалы представленные на сайте исключительно с целью ознакомления читателями и не преследуют коммерческих целей или нарушение авторских прав. Обратная связь - 18.191.26.53 (0.218 с.) |

,

, is the work spent on specimen failure at the test,

is the work spent on specimen failure at the test, are defined to within 0,1 kg×m/сm2 (at the International system of units 1 kg×m/сm2 is equal to ~ 10-1 МN×m/m2).

are defined to within 0,1 kg×m/сm2 (at the International system of units 1 kg×m/сm2 is equal to ~ 10-1 МN×m/m2).

by serial curves of impact toughness;

by serial curves of impact toughness;